Professional Documents

Culture Documents

Wheel & Axle

Uploaded by

hayatmdazhar0 ratings0% found this document useful (0 votes)

135 views18 pagesThe document discusses wheel maintenance procedures for rolling stock. It describes how wheels must be paired during wheel changes based on diameter to ensure equal wear. It then lists and defines various wheel defects like sharp flanges, thin flanges, and hollow tires that can develop during use. Threshold measurements are provided for determining when wheel defects require replacement. The document also discusses worn wheel profiles used to increase wheel life and describes the single bearing axle box assembly typically used in Indian railway passenger coaches.

Original Description:

jjj

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses wheel maintenance procedures for rolling stock. It describes how wheels must be paired during wheel changes based on diameter to ensure equal wear. It then lists and defines various wheel defects like sharp flanges, thin flanges, and hollow tires that can develop during use. Threshold measurements are provided for determining when wheel defects require replacement. The document also discusses worn wheel profiles used to increase wheel life and describes the single bearing axle box assembly typically used in Indian railway passenger coaches.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

135 views18 pagesWheel & Axle

Uploaded by

hayatmdazharThe document discusses wheel maintenance procedures for rolling stock. It describes how wheels must be paired during wheel changes based on diameter to ensure equal wear. It then lists and defines various wheel defects like sharp flanges, thin flanges, and hollow tires that can develop during use. Threshold measurements are provided for determining when wheel defects require replacement. The document also discusses worn wheel profiles used to increase wheel life and describes the single bearing axle box assembly typically used in Indian railway passenger coaches.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 18

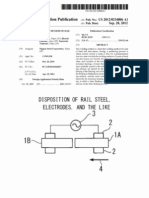

The movement of rolling stock on the track is

possible only with the help of wheels. The

complete wheel set is shown in the figure with

the assembly components.

PAIRING OF WHEELS

At the time of wheel changing the pairing to be

done where Diameter of wheel is the criteria.

So when wheel change of any Rolling Stock

under taken then, the measurement of wheel

(except the defective one) to be taken and wheel

set to be satisfy the following conditions.

In same Trolley Between the Trolleys

5 mm 13mm

New wheel Diameter. Condemning Diameter

915 mm 813 mm

Wheel Diameter

The following defects developed on the wheel

during its run.

Sharp Flange

Radius too small (RTS) at the root of the flange

Thin flange

Deep flange

Hollow tyre

Flat place on tyre

Wheel gauge slack/tight

Wheel cracks

Wheel diameter reaches below condemning limit

Tyre profile is checked by TYRE DEFECT

GAUGE.

Sharp Flange Flat Place

Radius too Small

Deep Flange

Hollow Tyre

Thin Flange

SHARP FLANGE

When the flange tip radius reached to less than 5mm,

its forms a fine sharp edge and the flange is called

sharp flange. Due to this the wheel set can take two

roads at slightly gapping point.

RADIUS TOO SMALL AT THE ROOT OF FLANGE

When radius at root of the flange becomes less than

13mm, it is called radius to small.

THIN FLANGE

When thickness of the flange reduced to 16mm, the

flange is called thin flange. But for higher speed

coaches (run on 110 KMPH or more ) the allowable

flange thickness is 22mm.

DEEP FLANGE

Due to excessive wear on tread, the height of the flange

increases and the flange is called Deep flange. When

the depth of the flange measured from the top of the

flange to a point on the tread (63.5mm away from the

back of BG wheel) becomes more than 35mm it is call

deep flange.

HOLLOW TYRE

When excessive wear takes place on the tread of the

tyre, the projection of the outer edge of the wheel tread

below the hallow of the tyre exceeds 5mm, the worn

tread is called hollow tyre.

FLAT PLACE

Due to wheel skidding or brake binding the tread of the

wheel becomes flat called Flat place on tyre.

The maximum permissible value of flatness on a BG

wheel is Coaching stock-50mm.

RADIUS TOO SMALL (R.T.S)

Worn Profile

New Profile

DEEP FLANGE & HALLOW TYRE

New Profile

Hollow Tyre more

than 5mm

Worn Profile

THIN FLANGE

Worn Profile

New Profile

13mm

New Profile

Worn Profile

SHARP FLANGE

Flat Place

FLAT PLACE

EXCESSIVELY WORN OUT & DEEP FLANGE FLATE SURFACE

EXCESSIVELY DEPTH - 35mm

THIN FLANGE

SHARP FLANGE

ROOT RADIUS TOO SMALL DEPTH OF FLANGE

WHEEL GAUGE SLACK/TIGHT

Wheel gauge Standard -1600mm

Minimum - 1599mm

Maximum - 1602mm

Wheel should be gauged after the same

being taken out from the trolley (i.e. in no

load condition)

In addition to normal checks exercised on wheel

condition during primary / secondary

maintenance of coach a detailed inspection of

wheels should be done for the following defects.

Shattered Rim Fracture on the tread or flange.

Spread Rim- Spreading the rim on front face.

Shelled tread- Shelling, break out piece of metal,

fine thermal cracks.

Thermal cracks- Decoloration or blue-black

heating mark, crack on tread in a transverse or

radial direction.

Heat checks- Dense cracks on tread or heating

& cooling cycle.

WORN WHEEL PROFILE

To increase the life of the wheel sets by reducing least

possible materials at the time of turning, a new profile

instead of IRS profile has been inducted call WORN

WHEEL PROFILE

There are three intermediate sizes of WWP.

Stage I Flange thickness 25mm, Flange tip radius-

11.5mm, Root radius 14mm

Stage-II Flange thickness -22mm, Flange tip radius-

10mm , Root radius-14mm

Stage-III Flange thickness -20mm, Flange tip radius-

9mm , Root radius-14mm

N.B: Wheel of Stage-I will be fitted to high speed coach at

the of wheel changing .

Intermediate WWP Stage III for High Speed

Coaches

AXLE BOX ASSEMBLY

In passenger coaches of Indian Railway

system, only single bearing type axle box

arrangement is used. The inner ring of the

bearing is provided with either a cylindrical

bore (Direct Mounted type) or with a taper

bore and withdrawal sleeve (Sleeve

Mounted type). All new passenger

coaches built by Indian Railways, use only

direct mounted type spherical roller

bearings.

ROLLER BEARINGS

Spherical roller bearing consist of an outer

ring having a continuous spherical

raceway within which operate, two rows of

barrel shaped rollers, which in turn are

guided by an inner ring with two raceways

separated by a centre rib. The spherical

roller bearings have self-aligning

properties and therefore can automatically

adjust to any deviation in the centre line of

the axle.

You might also like

- Mechanical Hand-Outs on Wheel Types, Profiles, Defects & TerminologyDocument25 pagesMechanical Hand-Outs on Wheel Types, Profiles, Defects & TerminologyTapas kumarNo ratings yet

- Track ManualDocument22 pagesTrack ManualSivaneswaran SabaratnamNo ratings yet

- Elastic FasteningsDocument74 pagesElastic FasteningsMohamad SaquibNo ratings yet

- WHEEL DEFECTS & WHEEL SHELLING (Soft Copy) - 0Document17 pagesWHEEL DEFECTS & WHEEL SHELLING (Soft Copy) - 0mehrotraprashant06No ratings yet

- Bogie SKRDocument24 pagesBogie SKRhayatmdazharNo ratings yet

- Civil Engineering Student Presents Terms Related to Ballast and Railway Track FormationDocument68 pagesCivil Engineering Student Presents Terms Related to Ballast and Railway Track FormationVetri VelanNo ratings yet

- Dynamics of Railway Vehicles: - Tractive & Braking Motion - Parasitic MotionDocument14 pagesDynamics of Railway Vehicles: - Tractive & Braking Motion - Parasitic MotionBimal BhattacharyaNo ratings yet

- Uic Comfort Tests Investigation of Ride Comfort and Comfort Disturbance On Transition and Circular CurvesDocument130 pagesUic Comfort Tests Investigation of Ride Comfort and Comfort Disturbance On Transition and Circular CurvescezarNo ratings yet

- CEASAR and PDMS SoftwareDocument10 pagesCEASAR and PDMS Softwarehayatmdazhar100% (1)

- CEASAR and PDMS SoftwareDocument10 pagesCEASAR and PDMS Softwarehayatmdazhar100% (1)

- Rolling StockDocument130 pagesRolling StockMonu ChaudharyNo ratings yet

- Write Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersDocument9 pagesWrite Like An Academic: Designing An Online Advanced Writing Course For Postgraduate Students and ResearchersLexi TronicsNo ratings yet

- Braking DistanceDocument11 pagesBraking Distancekr_abhijeet72356587100% (1)

- CBCDocument15 pagesCBCabheypriyaNo ratings yet

- Eurox Cross Flow ScrubberDocument8 pagesEurox Cross Flow ScrubberRobin LayogNo ratings yet

- Innovations in Coach Design - SK Suri RCFDocument74 pagesInnovations in Coach Design - SK Suri RCFraveenNo ratings yet

- Introduction Handbook On FIAT BogieDocument95 pagesIntroduction Handbook On FIAT BogieVijay Anand100% (2)

- Mathcad - Ampacity CalculationDocument76 pagesMathcad - Ampacity CalculationAlex Ribeiro100% (4)

- Draft Training Module On LHB Coaches For JEs SSEsDocument12 pagesDraft Training Module On LHB Coaches For JEs SSEsRajeev ranjan kumar100% (1)

- Points and Crossings 2Document52 pagesPoints and Crossings 2dkaviti100% (2)

- Wheel DefectsDocument13 pagesWheel Defectsdeep0987654321100% (4)

- Flash Butt Welding Method for Rail Steel with Controlled Heat-Affected ZoneDocument20 pagesFlash Butt Welding Method for Rail Steel with Controlled Heat-Affected ZoneRakesh SrivastavaNo ratings yet

- Track MaintenanceDocument39 pagesTrack MaintenanceAbdulhmeed Mutalat100% (1)

- GMRT2466 Iss 1 - Railway WheelsetsDocument90 pagesGMRT2466 Iss 1 - Railway WheelsetsSofia D'AlessandroNo ratings yet

- Factors Effecting PerformanceDocument47 pagesFactors Effecting Performancebembie83No ratings yet

- Failures of Bearings and Axles in Railway Freight WagonsDocument11 pagesFailures of Bearings and Axles in Railway Freight WagonsLuis LozadaNo ratings yet

- RDSO Training Report Wagon PDFDocument55 pagesRDSO Training Report Wagon PDFVikas RajpootNo ratings yet

- B10 Life of An Axle ShaftDocument8 pagesB10 Life of An Axle ShaftGaddipati Mohankrishna100% (1)

- RDSO Training Report WagonDocument55 pagesRDSO Training Report WagonGaurav Pathak0% (1)

- Evaluation of Design of Rear AxleDocument6 pagesEvaluation of Design of Rear AxleAbhijeet PandeyNo ratings yet

- ICF Bogie: Sanjay Kumar Lecturer/IRIMEEDocument35 pagesICF Bogie: Sanjay Kumar Lecturer/IRIMEENeelesh SinghNo ratings yet

- E 410Document9 pagesE 410rahatNo ratings yet

- Carriage WorkshopDocument26 pagesCarriage WorkshopSwethaNo ratings yet

- Seminar Report Railway's WheelsDocument33 pagesSeminar Report Railway's WheelsAli Asgar KhanNo ratings yet

- BOGIE Book Final25.03Document48 pagesBOGIE Book Final25.03Anandhasekar100% (1)

- Retrofit BMBS InstructionsDocument3 pagesRetrofit BMBS InstructionsPradipta SahooNo ratings yet

- Advanced Bogie Brakes Improve Safety and EfficiencyDocument5 pagesAdvanced Bogie Brakes Improve Safety and EfficiencyAndy AcousticNo ratings yet

- Rail Wheel Interaction 02Document44 pagesRail Wheel Interaction 02kr_abhijeet723565870% (1)

- AttachmentDocument44 pagesAttachmentSekhar KantipakaNo ratings yet

- LWR BasicsDocument53 pagesLWR BasicsViswanadh Lvs KuchibhotlaNo ratings yet

- Abaqus Unified Intro-SummaryDocument32 pagesAbaqus Unified Intro-SummaryJugurtha MassinissaNo ratings yet

- ME2114-2 Combined Bending & TorsionDocument11 pagesME2114-2 Combined Bending & TorsionWei QuanNo ratings yet

- Railway Braking PDFDocument6 pagesRailway Braking PDFTANYA AGARWALNo ratings yet

- Bogie Mounted Air Brake SystemDocument14 pagesBogie Mounted Air Brake SystemPradipta SahooNo ratings yet

- Pandrol DFC - Operation & Maintenance ManualDocument20 pagesPandrol DFC - Operation & Maintenance ManualOon Chee Koon100% (1)

- Obhs & CTSDocument39 pagesObhs & CTSManohara BabuNo ratings yet

- Analysis and Design of Tractor Rear Axle Using Finite Element Method - 52881Document5 pagesAnalysis and Design of Tractor Rear Axle Using Finite Element Method - 52881Zulfadzli RidzuanNo ratings yet

- Final Report Complete Reduction in TR Exam Time 29.1.2020 PDFDocument23 pagesFinal Report Complete Reduction in TR Exam Time 29.1.2020 PDFMk SharmaNo ratings yet

- Pelgage Voidmeter: Essential Tool For Measuring Track GeometryDocument2 pagesPelgage Voidmeter: Essential Tool For Measuring Track GeometrySivaneswaran SabaratnamNo ratings yet

- Equilibrium Elevation.: FC (W V) / (G R)Document12 pagesEquilibrium Elevation.: FC (W V) / (G R)BEN NARENDRANNo ratings yet

- Coil Spring Groups: Engineering Standard Rolling StockDocument10 pagesCoil Spring Groups: Engineering Standard Rolling Stockoliveira1305No ratings yet

- (IRFCA) Indian Railways FAQ - Rolling Stock - IDocument20 pages(IRFCA) Indian Railways FAQ - Rolling Stock - ILaxman SahooNo ratings yet

- ICF Bogie OverhaulingDocument10 pagesICF Bogie OverhaulingSaptarshi PalNo ratings yet

- Revised Codal LifeDocument11 pagesRevised Codal Lifebvdas0% (1)

- Quality Audit Check Sheet For Wagon DepotDocument32 pagesQuality Audit Check Sheet For Wagon Depotmukesh_singh_16100% (2)

- Datasheet 5C-2Document2 pagesDatasheet 5C-2mkashkooli_scribd0% (1)

- Railways, Rail GaugesDocument45 pagesRailways, Rail GaugesabubakarNo ratings yet

- RCFDocument16 pagesRCFAmitShuklaNo ratings yet

- H Type CouplerDocument10 pagesH Type CouplerSantosh Sharma50% (2)

- Course Book Mse MJR Iii Workshop PDFDocument133 pagesCourse Book Mse MJR Iii Workshop PDFPratap Singh GangwarNo ratings yet

- RCF KapurthallaDocument18 pagesRCF KapurthallaSudhir Kumar50% (2)

- Axle CounterDocument30 pagesAxle CounterArvind NangareNo ratings yet

- General and Subsidary Rules South Central RailwayDocument501 pagesGeneral and Subsidary Rules South Central Railwayhodibaaba1No ratings yet

- South East Central Railway (SECR) Bilaspur Mechanical Vocational Training Report 1-Haxxo24 I IDocument42 pagesSouth East Central Railway (SECR) Bilaspur Mechanical Vocational Training Report 1-Haxxo24 I Ihaxxo24No ratings yet

- Types of Railway Turnouts and Their ComponentsDocument10 pagesTypes of Railway Turnouts and Their ComponentsrobbsNo ratings yet

- UIC 515-1 OR - General Provisions For Trailer Bogie Compone - 1Document25 pagesUIC 515-1 OR - General Provisions For Trailer Bogie Compone - 1xxNo ratings yet

- Immediate Payment NotificationsDocument2 pagesImmediate Payment NotificationshayatmdazharNo ratings yet

- Ftyk Ifj"Kn) Lhrke +H R'RH Ek? Fed F'K (KD Fu Kstu & 2012 Vksicaf/Kd Es/Kk LWPH Fo"K %& Lald'R Izf'Kf (KRDocument42 pagesFtyk Ifj"Kn) Lhrke +H R'RH Ek? Fed F'K (KD Fu Kstu & 2012 Vksicaf/Kd Es/Kk LWPH Fo"K %& Lald'R Izf'Kf (KRhayatmdazharNo ratings yet

- Solar Energy 21 SepDocument21 pagesSolar Energy 21 SephayatmdazharNo ratings yet

- TL1 2008Document31 pagesTL1 2008hayatmdazharNo ratings yet

- Measurement of Solar Energy RadiationDocument11 pagesMeasurement of Solar Energy RadiationhayatmdazharNo ratings yet

- Tank CleaningDocument2 pagesTank CleaninghayatmdazharNo ratings yet

- Non Conventional SyllabusDocument1 pageNon Conventional SyllabushayatmdazharNo ratings yet

- Cad Cam Lab FinalDocument16 pagesCad Cam Lab FinalhayatmdazharNo ratings yet

- Energy Reserve and Estimates: Manoj Kumar Jha Asst. Professor, Mechanical Engineering Department, Sharda UniversityDocument18 pagesEnergy Reserve and Estimates: Manoj Kumar Jha Asst. Professor, Mechanical Engineering Department, Sharda UniversityhayatmdazharNo ratings yet

- Photovoltaic Solar SystemsDocument32 pagesPhotovoltaic Solar SystemshayatmdazharNo ratings yet

- TL1 2008Document31 pagesTL1 2008hayatmdazharNo ratings yet

- DampingDocument24 pagesDampinghayatmdazharNo ratings yet

- Safety Hazard Identification On Construction ProjectsDocument19 pagesSafety Hazard Identification On Construction ProjectshayatmdazharNo ratings yet

- ConsultancyDocument2 pagesConsultancyhayatmdazharNo ratings yet

- Qwerty keyboard layout guideDocument1 pageQwerty keyboard layout guidehayatmdazharNo ratings yet

- Boiler Safety: Furnace InspectionDocument4 pagesBoiler Safety: Furnace Inspectionhayatmdazhar100% (1)

- Ftyk Ifj"Kn) Lhrke +H R'RH Ek? Fed F'K (KD Fu Kstu & 2012 Vksicaf/Kd Es/Kk LWPH Fo"K %& Lald'R Izf'Kf (KRDocument42 pagesFtyk Ifj"Kn) Lhrke +H R'RH Ek? Fed F'K (KD Fu Kstu & 2012 Vksicaf/Kd Es/Kk LWPH Fo"K %& Lald'R Izf'Kf (KRhayatmdazharNo ratings yet

- SSC - Nic.in Notice Examnotice CGLE-2014 NoticeDocument40 pagesSSC - Nic.in Notice Examnotice CGLE-2014 NoticehayatmdazharNo ratings yet

- Ielts Venue 07jul 12 KTM PokharaDocument14 pagesIelts Venue 07jul 12 KTM PokharahayatmdazharNo ratings yet

- Product Broucher All ProductsDocument10 pagesProduct Broucher All ProductshayatmdazharNo ratings yet

- 01 EcologyDocument24 pages01 EcologykhilanvekariaNo ratings yet

- D T C +TIME+TABLE+dt +19 12 13Document723 pagesD T C +TIME+TABLE+dt +19 12 13Kehs IhbaNo ratings yet

- Area Manager Product Sales - JDDocument1 pageArea Manager Product Sales - JDhayatmdazharNo ratings yet

- HVAC Design Engineer: Mistral Airconditioning Services (MEP Consultanat)Document1 pageHVAC Design Engineer: Mistral Airconditioning Services (MEP Consultanat)hayatmdazharNo ratings yet

- Engineer Job Description FormDocument1 pageEngineer Job Description FormhayatmdazharNo ratings yet

- Componentsofcomputer 130602112330 Phpapp01Document13 pagesComponentsofcomputer 130602112330 Phpapp01hayatmdazharNo ratings yet

- Process Sizing CriteriaDocument91 pagesProcess Sizing CriteriaMohammad BadakhshanNo ratings yet

- An70983 001-70983Document24 pagesAn70983 001-70983अमरेश झाNo ratings yet

- Shivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursDocument4 pagesShivam Public School: Half Yearly Exam (2019-20) Class-VII Subject - S.S.T Time:3 HoursSHIVAM TAYALNo ratings yet

- Grade 6 Science PuzzleDocument4 pagesGrade 6 Science Puzzlemargie riveraNo ratings yet

- Design of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockDocument10 pagesDesign of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockStalynMEcNo ratings yet

- Teaching Methodology (Handout)Document1 pageTeaching Methodology (Handout)Sharjeel Ahmed KhanNo ratings yet

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 pagesUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWNo ratings yet

- MGS3750 28FDocument4 pagesMGS3750 28FAndi Z Pasuloi PatongaiNo ratings yet

- ANR causes and solutionsDocument2 pagesANR causes and solutionsPRAKHAR SRIVASTAVANo ratings yet

- VNX Power UP Down ProcedureDocument8 pagesVNX Power UP Down ProcedureShahulNo ratings yet

- Sources of Release Schedule For Hazardous Area ClassificationDocument1 pageSources of Release Schedule For Hazardous Area ClassificationMachmud Ragil'sNo ratings yet

- Educational Technology & Education Conferences - January To June 2016 - Clayton R WrightDocument93 pagesEducational Technology & Education Conferences - January To June 2016 - Clayton R WrightEsperanza Román MendozaNo ratings yet

- Performance Estimation of Ofdm-Wimax Network: Vishal Sharma & Navneet KaurDocument8 pagesPerformance Estimation of Ofdm-Wimax Network: Vishal Sharma & Navneet KaurTJPRC PublicationsNo ratings yet

- PJ1117CM-2 5VDocument6 pagesPJ1117CM-2 5VАлексей ГомоновNo ratings yet

- RDSO - Specification No.M&C NDT 125 2004 Rev IDocument6 pagesRDSO - Specification No.M&C NDT 125 2004 Rev INiking ThomsanNo ratings yet

- GestioIP 3.0 Installation GuideDocument17 pagesGestioIP 3.0 Installation GuidepiterasNo ratings yet

- Transient and Random VibrationDocument19 pagesTransient and Random VibrationAman SharmaNo ratings yet

- Pivot Part NumDocument2 pagesPivot Part Numrossini_danielNo ratings yet

- Man Power PlanningDocument5 pagesMan Power PlanningKarthik AchinNo ratings yet

- Grant Park Platform Bedroom Set Furniture RowDocument1 pageGrant Park Platform Bedroom Set Furniture Rowjyzjz6sr65No ratings yet

- Touch Screen TechnologyDocument18 pagesTouch Screen TechnologySmîlērNo ratings yet

- Infantry WeaponsDocument61 pagesInfantry WeaponsKaran SahotaNo ratings yet

- January 2021 price list for Petro motor oils and diesel engine oilsDocument2 pagesJanuary 2021 price list for Petro motor oils and diesel engine oilsSAFIR ULLAHNo ratings yet

- Nec 2006Document59 pagesNec 2006loots69No ratings yet

- G12gasa Group5 PR2Document7 pagesG12gasa Group5 PR2Lizley CordovaNo ratings yet

- Breaking Water Protection Paradigms: RTM Composite DomesDocument52 pagesBreaking Water Protection Paradigms: RTM Composite DomesaerostressNo ratings yet