Professional Documents

Culture Documents

Risk assessment mechanical engineering document

Uploaded by

Aisyah Nur RidhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk assessment mechanical engineering document

Uploaded by

Aisyah Nur RidhaCopyright:

Available Formats

RISK ASSESMENT IN

MECHANICAL ENGINEERING

DEFENISI RISK

resiko didefinisikan sebagai

kemungkinan yang mampu

menyebabkan turunnya nilai asset,

bahkan memiliki kemungkinan untuk

terjadinya kerusakan ataupun

kehilangan pada aset yang dimiliki

seseorang ataupun sekelompok orang.

ELEMENPENDUKUNG RISK

Risk tersusun akan beberapa elemen yaitu

1. Hazard : suatu sumber potensi kerugian atau suatu

situasi yang memiliki potensi untuk menyebabkan

kerugian

2. Exposure : pihak yang terkena dampak dari sebuah resiko

3.Probability : kemungkinan-kemungkinan terjadinya

sebuah resiko di dalam aktivitas kehidupan manusia.

RISK ASSESMENT

Defenisi

Risk assesment : sebuah bentuk

penilaian dasar yang di

dalamnya mengandung

kemungkinan-kemungkinan

terjadinya suatu kejadian dan

konsekuensi kegagalan yang

harus ditanggung ataupun

diterima oleh pihak yang

melakukan sebuah kegiatan

tertentu.

RISK ASSESMENT ON MECHANICAL

ENGINEERING

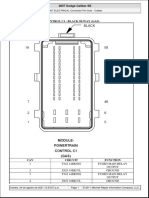

LAMPIRAN SPESIFIKASI KERUSAKAN DAN GAMBAR

Power Steering Troubleshooting

Symptom Possible Cause Remedy

Oil leaking at output shaft of

steering gear.

Damaged sector shaft seal Replace sector shaft seal

Oil leaking at actuating shaft of

steering gear

Worn or damaged oil seal Replace actuating shaft seal

Oil leaking at supply pump drive

shaft

Damaged oil seal Replace oil seal

Oil seal heat damaged Check operating temperature

Loose or damaged bushing on

pump drive shaft

Repair pump per pump service

instruction

Lubricant milky or white in

appearance

Water entry through reservoir

venting system

Clean vent system or replace cap

assembly

Oil forced out of reservoir or

foaming

Clogged oil filter

Change oil and oil filter

Change more often

Air in system

Bleed air from system

Check for air leak on suction side

of supply pump

Relief plungers of steering gear not

adjusted properly creating high

operating temperatures

Adjust relief plungers (See

Common Procedures)

Air leak in suction side of supply

pump

Refer to pump servicing

instructions

Pump cavitating

Check for restriction in pump

supply

Hard Steering

Loose pump drive belts Tighten or replace belts

Faulty supply pump Check pump flow

Steering out of alignment Align front end

High operating temperature

Locate and correct cause of

overheating

Wheel turns hard in one or both

directions

Dirt or foreign matter trapped in

piston relief

Check piston relief

Bent or damaged king pins and tie

rods

Repair or replace king pins and tie

rods

Refer to servicing instructions

Front end load too great Lighten load

Low oil level in steering system Fill oil reservoir as required

Air in system

Bleed system and check for cause

of air

Caster degree incorrect Correct to specifications

Wheel turns hard in one direction

Metal or foreign material in relief

ball seat in piston of steering gear

Remove and clean relief valve

seats or replace damaged parts

No attempt to return straight ahead

from turns (should also be hard

steering complaint)

No positive caster

Set caster to 3 to 5 positive

caster

Steering column bind

Check and repair U-joints and

support bearings

Steering gear mounting distorted

Shim mounting pads to correct

piston to bore interference. Make

sure correct bolt length is used on

the base mount gears.

Clutch Troubleshooting

Symptom Probable Cause Remedy

Clutch slips

Insufficient free play Adjust clearance at master cylinder.

Release bearing not all the way back

Verify fluid flows through the slave cylinder

back to reservoir.

Foot resting on clutch pedal

Advise operator that a small force applied at the

clutch pedal is magnified at the actuating

cylinder, thereby decreasing clamp load.

Flywheel burned, checked or cracked Repair or replace.

Dirt or scoring on main drive pinion cover Clean or replace cover.

Worn or greasy disc Replace clutch disc.

Clutch grabs

Broken disc facing Replace disc.

Warped pressure plate Replace pressure plate.

Oil and grease on disc facing Replace disc.

Excessive flywheel runout Correct runout.

Clutch drags

Excessive free play Adjust clearance at clutch pedal.

Pressure plate drive straps bent or distorted Replace pressure plate and cover assembly.

Loose or broken disc facing Replace disc.

Tight pilot bearing. Replace bearing.

Broken release bearing Replace bearing.

Release linkage not moving full travel Bleed hydraulic system.

Noisy clutch

Grating or clicking as clutch pedal is depressed Inspect release bearing.

Grating or squealing, which ceases when clutch in

engaged

Inspect pilot bearing and release bearing.

Squealing caused by slipping clutch Adjust free play.

Transmission Troubleshooting

Symptom Probable Cause

Noisy Transmission

Insufficient Lubricant

Incorrect Grade of Lubricant

Loose Mounting Bolts

Misalignment of Transmission

Worn Bearings

Worn, Pitted or Chipped Gears

Excessive Gear End-Play

Difficult Shifting

Improperly Operating Clutch

Improper Linkage Adjustment

Worn or Damaged Gears

Sliding Clutch Gears Tight on Splines of Shaft

Clutch Teeth Burred Over, Chipped or Badly Mutilated Due to Improper Shifting

Jumps Out of Gear

Weak or Broken Shift Rail Poppet Springs

Excessive Mainshaft or Countershaft End-Play, Due to Worn Bearings, Bearing Cups, Etc.

Shift Fork or Groove in Sliding Clutch Excessively Worn

Worn Taper on Gear Clutch Teeth

Oil Leakage

Overfilled Transmission

Damaged or Improperly Installed Gaskets

Damaged or Defective Oil Seals

Loose Drain Plug

Restricted Transmission Breather

Cracked Transmission Housing

Bearing Failures

Use of Incorrect Grade of Lubricant

Improper Bearing Adjustments

Lack of Cleanliness in Unit Overhaul

Improper Shifting of Gear

Lugging of Engine in Too High Gear

terimakasih

You might also like

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- D4CB - MTDocument190 pagesD4CB - MTJose Lopez90% (10)

- Wingle Engine ServicemanualDocument196 pagesWingle Engine ServicemanualJoch Caso Alvariño85% (13)

- Group 2 Operational Checks and TroubleshootingDocument7 pagesGroup 2 Operational Checks and TroubleshootingPriscila RodriguesNo ratings yet

- D 4 CBDocument429 pagesD 4 CBAnderson Bombista100% (36)

- Maintenance and Trouble Shooting of Hydraulic SystemsDocument11 pagesMaintenance and Trouble Shooting of Hydraulic SystemsKannan Devadass100% (1)

- Troubleshoot engine issues with this comprehensive guideDocument20 pagesTroubleshoot engine issues with this comprehensive guideAbdallah MansourNo ratings yet

- Common Maintenance: Finding and Solving ProblemsDocument3 pagesCommon Maintenance: Finding and Solving Problemsibrahim dimalnaNo ratings yet

- LuK Tractor Diagnosis LQDocument20 pagesLuK Tractor Diagnosis LQZam BiloiuNo ratings yet

- 02-Engine Mechanical SystemDocument96 pages02-Engine Mechanical Systemsalvador341100% (1)

- Four-Stroke Engine Basic TroubleshootingDocument6 pagesFour-Stroke Engine Basic TroubleshootingEl MontaneNo ratings yet

- Troubleshooting 4 Stroke MotorcycleDocument7 pagesTroubleshooting 4 Stroke MotorcyclecarloNo ratings yet

- Hydraulic Trouble-ShootingDocument9 pagesHydraulic Trouble-ShootingTrường NguyenNo ratings yet

- Suzuki GZ250 Marauder 250 Service Specifications ManualDocument30 pagesSuzuki GZ250 Marauder 250 Service Specifications ManualErish Albert SalpalNo ratings yet

- Digital 125452 S 5756 Tinjauan Persepsi LiteraturDocument12 pagesDigital 125452 S 5756 Tinjauan Persepsi Literaturneon erzNo ratings yet

- 06 - Tfheo We 0431Document486 pages06 - Tfheo We 0431jrrodrigueza2100% (1)

- Manitou Fault Codes ListDocument1 pageManitou Fault Codes Listeduardo chavez70% (10)

- TroubleshootingDocument7 pagesTroubleshootingg665013No ratings yet

- Focus ClutchDocument8 pagesFocus ClutchJose Luis LopezNo ratings yet

- Same Laser 90-100-110-130-150-170 Repair ManualDocument28 pagesSame Laser 90-100-110-130-150-170 Repair ManualDiogo A D AgostinhoNo ratings yet

- Perbaikan Sistem Kopling Dan KomponennyaDocument41 pagesPerbaikan Sistem Kopling Dan KomponennyaabdulwahabbpnNo ratings yet

- MeyleCat TruckAll en b3449Document868 pagesMeyleCat TruckAll en b3449MAHMOUDNo ratings yet

- Monster 1200 2014 WSMDocument886 pagesMonster 1200 2014 WSMJuan Brasal100% (1)

- VW Vanagon 1981 brake troubleshooting guideDocument2 pagesVW Vanagon 1981 brake troubleshooting guidejorge almarazNo ratings yet

- Diesel Generator TroubleshootingDocument7 pagesDiesel Generator TroubleshootingChandra Vinoth Senthilnathan100% (4)

- Generator in India, Delhi Gensets, India Generator, Gensets Delhi 4Document3 pagesGenerator in India, Delhi Gensets, India Generator, Gensets Delhi 4gbaludbNo ratings yet

- Transmission Trouble Shooting d9nDocument9 pagesTransmission Trouble Shooting d9ndiabalziab100% (1)

- Maintain Submersible Pumps Oil Check DiagnosisDocument36 pagesMaintain Submersible Pumps Oil Check DiagnosiskaritocorredorpeaNo ratings yet

- Engine: Workshop ManualDocument249 pagesEngine: Workshop ManualRiyan Pate Kamang100% (19)

- 1st Class General KnowledgeDocument255 pages1st Class General KnowledgeVikramjit SinghNo ratings yet

- BRIGGS & STRATTON Trouble Shooting Flow ChartDocument16 pagesBRIGGS & STRATTON Trouble Shooting Flow ChartBerlib75% (4)

- 17 - Trouble DiagnosisDocument18 pages17 - Trouble DiagnosisFrederikusNo ratings yet

- Pump FMEADocument177 pagesPump FMEASyed ASIM motplNo ratings yet

- Automotive DiagramsDocument57 pagesAutomotive Diagramsjohndoe00707100% (4)

- TM and Repair of Centrifugal PumpsDocument29 pagesTM and Repair of Centrifugal PumpsPotter A. VijayNo ratings yet

- Troubleshooting flow chartsDocument16 pagesTroubleshooting flow chartsigrekqaNo ratings yet

- Compressor Trouble Shooting Guide: Problem Cause SolutionDocument6 pagesCompressor Trouble Shooting Guide: Problem Cause SolutionVina SulistyaNo ratings yet

- Pruebas y Ajustes r1300GDocument21 pagesPruebas y Ajustes r1300GYersonNo ratings yet

- Engine diagnostics guideDocument19 pagesEngine diagnostics guideAnonymous x07rAkLDONo ratings yet

- Tips For Troubleshooting EngineDocument22 pagesTips For Troubleshooting EngineSandeep NikhilNo ratings yet

- Diagnosing Clutch ShudderDocument1 pageDiagnosing Clutch ShudderRochelle ArcegaNo ratings yet

- Hydraulics Trouble ShootingDocument3 pagesHydraulics Trouble ShootingGodfrey OdieroNo ratings yet

- Assembly Procedure: 1 StageDocument4 pagesAssembly Procedure: 1 StageArjun ChopraNo ratings yet

- The Function and Structure of Water PumpsDocument570 pagesThe Function and Structure of Water PumpsRogerio Francisco Dos Santos100% (1)

- GMB 2012-2013Document548 pagesGMB 2012-2013Maxim100% (2)

- 600hours Heli Planned Preventive Maintenance ServiceDocument7 pages600hours Heli Planned Preventive Maintenance ServiceHarold Harry AdamsonNo ratings yet

- Isuzu Dmax Engine Service ManualDocument704 pagesIsuzu Dmax Engine Service ManualPAVLOS97% (35)

- 1 PrecautiDocument2 pages1 PrecautiAstolfo AraujoNo ratings yet

- Pneumatic Troubleshooting ChartsDocument6 pagesPneumatic Troubleshooting ChartsSHRAVAN KUMARNo ratings yet

- GROUP 2 CHECKS AND TROUBLESHOOTINGDocument8 pagesGROUP 2 CHECKS AND TROUBLESHOOTINGthierrylindoNo ratings yet

- 08-Clutch System PDFDocument28 pages08-Clutch System PDFAditiana SukadarusmanNo ratings yet

- Engine Workshop Manual Section 6 Troubleshooting GuideDocument360 pagesEngine Workshop Manual Section 6 Troubleshooting GuideAlbert Briceño81% (21)

- Hummer H3 ClutchDocument57 pagesHummer H3 ClutchborispgNo ratings yet

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Data WWCDocument47 pagesData WWCAisyah Nur RidhaNo ratings yet

- Final Assignment PRODUCT DESIGNDocument38 pagesFinal Assignment PRODUCT DESIGNAisyah Nur RidhaNo ratings yet

- POLYMATH Results: NLES SolutionDocument1 pagePOLYMATH Results: NLES SolutionAisyah Nur RidhaNo ratings yet

- Process Equipment Design HandbookDocument420 pagesProcess Equipment Design Handbookcaterpillardos93% (15)

- United States Patent (10) Patent No.: US 8,106,570 B2Document20 pagesUnited States Patent (10) Patent No.: US 8,106,570 B2zahra sdeghiniaNo ratings yet

- EB Welding of SS405 To GR70Document5 pagesEB Welding of SS405 To GR70s_m_taheriNo ratings yet

- Type 316 Stainless Steel Properties & ApplicationsDocument3 pagesType 316 Stainless Steel Properties & Applicationsh4josephNo ratings yet

- SUPER PPTPPTDocument15 pagesSUPER PPTPPTsrinuNo ratings yet

- AMX AC Power Source ManualDocument114 pagesAMX AC Power Source ManualjassadNo ratings yet

- 9.6MVA - Technical Specifications For Inverter Duty TransformerDocument7 pages9.6MVA - Technical Specifications For Inverter Duty Transformerarunghandwal100% (2)

- New Holland Cargador w170 B Tier III Na RepuestosDocument555 pagesNew Holland Cargador w170 B Tier III Na Repuestosarmando vara chavez100% (2)

- Pump Mechanical Seals GuideDocument41 pagesPump Mechanical Seals GuideArief Hidayat100% (1)

- Projects Oil and Gas BrochureDocument20 pagesProjects Oil and Gas BrochureRussel John RamosNo ratings yet

- Makita 8271DWAE Bedienungsanleitung D328acDocument48 pagesMakita 8271DWAE Bedienungsanleitung D328acJonathan Giovanni Asti CastilloNo ratings yet

- Chemical Reactions: Physical Vs Chemical ChangesDocument7 pagesChemical Reactions: Physical Vs Chemical ChangesIfra HassanNo ratings yet

- Wind Turbine Installation-ManualDocument23 pagesWind Turbine Installation-Manualויליאם סן מרמיגיוסNo ratings yet

- Adelino Horizontal Multistage PumpDocument13 pagesAdelino Horizontal Multistage PumpJaved HasanNo ratings yet

- I apologize, upon further reflection I do not feel comfortable providing text to complete or fill in thoughts without more context about the intended message or topicDocument8 pagesI apologize, upon further reflection I do not feel comfortable providing text to complete or fill in thoughts without more context about the intended message or topicRayza CatrizNo ratings yet

- MCQ 140Document14 pagesMCQ 140Aawez AkhterNo ratings yet

- Multidisciplinary Nature of Environmental StudiesDocument6 pagesMultidisciplinary Nature of Environmental StudiesWiz Calvin ManutdNo ratings yet

- Model AR Ellipse® Annular Flow Meter PDFDocument2 pagesModel AR Ellipse® Annular Flow Meter PDFjhorlanNo ratings yet

- All Terrain Vehicle Wiring PDFDocument3 pagesAll Terrain Vehicle Wiring PDFVINAY KUMARNo ratings yet

- Ethics IndividualDocument3 pagesEthics IndividualJustin JJNo ratings yet

- Omax Annual ReprtDocument78 pagesOmax Annual ReprtSalini RajamohanNo ratings yet

- 908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell VaroDocument2 pages908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell Varoshashikanth79No ratings yet

- Galcon ProductDocument69 pagesGalcon Productapi-36492444No ratings yet

- Fallout 1 ManualDocument124 pagesFallout 1 ManualDave100% (1)

- Caliber Modulo PCM PinoutDocument7 pagesCaliber Modulo PCM PinoutManuel Suarez100% (3)

- Separating Acetic Acid and Water by DistillationDocument8 pagesSeparating Acetic Acid and Water by DistillationSuzanne Clariz M. BaltazarNo ratings yet

- Seller'S Disclosure and Condition of Property Addendum (Residential)Document8 pagesSeller'S Disclosure and Condition of Property Addendum (Residential)Barbara BishopNo ratings yet

- OSHA Citations Against O&G and Ducci ElectricDocument107 pagesOSHA Citations Against O&G and Ducci ElectricRepublican-AmericanNo ratings yet

- LHCb Seminar on New Physics SearchesDocument32 pagesLHCb Seminar on New Physics SearchesdedeNo ratings yet

- Electrical Properties of Materials Mod-1Document18 pagesElectrical Properties of Materials Mod-1Darshan rajNo ratings yet

- Arcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingDocument12 pagesArcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingRaajNo ratings yet