Professional Documents

Culture Documents

Classical Beam Theory Application

Uploaded by

PravinKulkarni0 ratings0% found this document useful (0 votes)

68 views20 pagesThis document discusses classical laminate theory for analyzing composite materials. It covers:

1) Defining stress-strain relationships for isotropic and anisotropic composite materials using stiffness matrices.

2) Describing how stresses and strains transform when moving between global and local coordinate systems, especially for angled plies.

3) Developing equations to relate mid-plane strains and curvatures to applied loads using the laminate stiffness matrix for a composite laminate.

4) Providing an example problem to calculate mid-plane strains/curvatures and stresses in a composite laminate under a given load.

Original Description:

Classical beam theory application

Original Title

Classical beam theory application

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses classical laminate theory for analyzing composite materials. It covers:

1) Defining stress-strain relationships for isotropic and anisotropic composite materials using stiffness matrices.

2) Describing how stresses and strains transform when moving between global and local coordinate systems, especially for angled plies.

3) Developing equations to relate mid-plane strains and curvatures to applied loads using the laminate stiffness matrix for a composite laminate.

4) Providing an example problem to calculate mid-plane strains/curvatures and stresses in a composite laminate under a given load.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

68 views20 pagesClassical Beam Theory Application

Uploaded by

PravinKulkarniThis document discusses classical laminate theory for analyzing composite materials. It covers:

1) Defining stress-strain relationships for isotropic and anisotropic composite materials using stiffness matrices.

2) Describing how stresses and strains transform when moving between global and local coordinate systems, especially for angled plies.

3) Developing equations to relate mid-plane strains and curvatures to applied loads using the laminate stiffness matrix for a composite laminate.

4) Providing an example problem to calculate mid-plane strains/curvatures and stresses in a composite laminate under a given load.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 20

Mechanics of composite lamina and laminate

(Classical Laminate Theory)

1

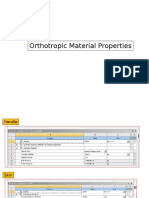

For a linear isotropic material in a 3D stress state, the stressstrain relationships as per Hookes law at a

point in an xyz orthogonal system in matrix form are :

Shear Modulus G = E/2(1+v)

Compliance matrix

[S]

Stiffness matrix [C]

Strain energy per unit volume is,

For Composite material which

are non-isotropic, generalized

Hookes law presents 36

constants in stiffness matrix

relating stresses & strains in an

1-2-3 orthogonal system

1 2

4

3

1

=

Stiffness for various types of materials

2

The stress strain relation in eq. 4 can be expressed as

where 4 = 23 , 5 = 31 , 6 = 12 and

4 = 23 , 5 = 31 , 6 = 12

So the strain energy equation can be expressed as

which is same as

Partial differential of SE equation gives and

So Cij = Cji and thus the 36 constants can be reduced to 21 constants for Anisotropic

material

Other cases of material

symmetry

# of constants

Monoclinic 13

Orthotropic 9

Transverse Orthotropic 5

Isotropic 2

3

Case of 2D angle lamina

Stresses in the global x-y and local 1-2

directions in the angle lamina are related

to each other through the angle of the

lamina, as,

For a 2D laminate all the laminae

are not in same directions and

some laminae are at an angle to

the global x-y direction

where [T], the transformation matrix is defined

as

c = Cos() and s = Sin()

4a

In terms of the strains,

Strain transformations relation

where

is Reuter matrix

[28]

So,

So,

The stress-strain relations can

be written in terms of

transformed reduced stiffness

matrix Q

ij

5

4b

5

Thus the normal, shear

stresses & strains are coupled

for a generally orthotropic

angular lamina and varies with

fiber angle.

For thin lamina with no out of

plane loads, the plane stress

condition gives

where

E1 = longitudinal Youngs modulus (in direction 1)

E2 = transverse Youngs modulus (in direction 2)

12 = major Poissons ratio while ij = ratio of ve

of

normal strain in j to normal strain in i when

load is

applied in i dir.

G12 = in-plane shear modulus (in plane 12)

5c

5b

Analysis of Failure theories of composite lamina

6

Theory Criteria Remarks

Maximum stress theory

(failure occurs if max normal or shear

stress in local axes exceeds ultimate

strength of lamina)

Similar to isotropic materials

and each stress component is

considered separate to others

Maximum strain theory

[St. Venant]

(failure occurs if max normal or shear

strain in local axes exceeds ultimate strain

of lamina)

Similar to max stress theory but

due to poissons ratio effect,

gives different results

Tsai hill theory

[Von Mises distortion energy theory]

(failure occurs when when the distortion

energy is greater than the failure

distortion energy of the material)

Considers the interaction

among the three strength

parameters 1, 2, 12

More conservative than above

2 for applicable stress

Does not give mode of failure

Close to experimental results

Tsai-Wu theory [Beltrami strain energy]

Distinguishes between tensile

and compressive strengths of

lamina

Gives better applicable stress

than all other theories

Close to experimental results

like Tsai-Hill theory

H6 = 0,

Stress strain analysis of composite laminates

7

[0/45/902/60/0] [0/45/60]s [0/45/902/60/0]

Stacking notations

Assumptions

each lamina is orthotropic,

homogeneous and elastic

Shear strains in xz and yz are

zero

Plane stress : z = xz = yz = 0

Displacements are small

compared to lamina thickness

and No inter-lamina slip

Resultant forces and moments on a

laminate

Laminate strain displacement relations

8

Relationship between displacements

w through the thickness of a plate to

mid-plane displacements u, v and

curvatures

u0, v0, w0 are displacements

at mid-plane and u, v, and w

are displacement at any point

in the thickness

u = u0 zx where =

u = u0 z

Similarly in y-z plane v = v0 - z

x =

xy

=

=

y =

Mid plane

strain

Mid plane

curvature

So

,

5d

9

The strain-displacement equations can be written in matrix form as

Stresses change over at ply

since Qij depend upon

material and ply orientation

Global stresses, strain can be transformed to local system 1-2 and so can be used to check failure

criteria

Next, we will find the mid-plane strains and curvatures when the loads are known

6

Laminate mid-plane strains and curvatures

10

Mid plane

Ply positioning inside a laminate

Consider a system of n laminae in a laminate each having thickness of tk with

h being total thickness of laminate. The z coordinate of various plies are,

Top surface

Top surface

Bottom surface Bottom surface

6b

11

If,

Nx, Ny = normal force per unit length

Nxy = shear force per unit length

Mx, My = bending moments per unit length

Mxy = twisting moments per unit length

Integrating stresses global stresses in each lamina

In matrix form,

12

So Eq 6 for relation of global stresses and mid-plane strains and curvatures can be written as,

Since mid-plane strains and curvatures are independent of z coord. and [Qk]

stiffness matrix is constant for each ply. Hence,

7a

7b

13

Considering ,

8a

8b

Extensional stiffness

matrix

Bending stiffness matrix

Coupling stiffness matrix

9

14

Relates in-plane

forces to in-plane

strains

Relates bending

moment to plate

curvatures

Couples force and

moments to mid-plane

strains, curvatures

10

15

Ref: Similar to Ex 4.3 from Mechanics of composite materials, A.K Kaw

A [0/30/45] glass/epoxy laminate is subjected to a load of Nx = Ny = 1000 N/m., Mx

= 50 N-m

Using the properties of unidirectional glass/epoxy below and assuming that each

lamina is 5 mm thick, aim is to find

1. Mid-plane strains and curvatures

2. Global and local stresses on top surface of 30 ply

3. Percentage of load, Nx, taken by each ply

Example Problem

Property Symbol Unit Value

Longitudinal elastic modulus E1 GPa 38.6

Transverse elastic modulus E2 Gpa 8.27

Major Poissons ratio 12 0.26

Shear modulus G12 Gpa 4.14

21 = 12 x E2/E1

= 0.26 X 8.27/38.6

= 0.0557

Steps

16

1. Find the value of the reduced stiffness matrix [Q] for each ply using its four

elastic moduli, E1, E2, 12, and G12 in Equation (5b).

2. Find the value of the transformed reduced stiffness matrix for each ply using

the [Q] matrix calculated in step 1 and the angle of the ply in Equation (5c)

3. Knowing the thickness, tk, of each ply, find the coordinate of the top and

bottom surface, hi, i = 1, n, of each ply, using Equation (6b).

4. Use the matrices from step 2 and the location of each ply from step 3 to find

the three stiffness matrices [A], [B], and [D] from Equation (9).

5. Substitute the stiffness matrix values found in step 4 and the applied forces

and moments in Equation (10).

6. Solve the six simultaneous equations (10) to find the mid-plane strains and

curvatures.

7. Now that the location of each ply is known, find the global strains in each ply

using Equation (5d).

8. For finding the global stresses, use the stressstrain Equation (5).

9. For finding the local strains, use the transformation Equation (4b).

10. For finding the local stresses, use the transformation Equation (4a).

Solution

17

For the 0 deg

ply,

= 39.17 GPa

= 2.182 GPa

= 8.392 GPa

= 4.14 GPa

39.17 2.18

0

2.18 8.39 0

0 0

4.14

For the 30 deg

ply

26.38 7.58 9.54

7.58 11.07 3.78

9.54 3.78 9.12

For the 45 deg

ply

17.11 9.38 -

6.65

9.38 17.11 -6.65

-6.65 -6.65 10.27

Aij =

39.17 2.18

0 2.18 8.39

0

0 0

4.14

x(-0.0025)-(-0.0075)x10

9

+

x(0.0025)-(-0.0025)x10

9

26.38 7.58 9.54

7.58 11.07 3.78

9.54 3.78 9.12

+

17.11 9.38 -

6.65 9.38 17.11 -6.65

-6.65 -6.65

10.27

x(0.0075)-(0.0025)x10

9

Aij =

41.33 9.57

1.45

9.57 18.29 -1.43

1.45 -1.43 11.77

x 10

6

Pa-

m

18

Bij = 1/2

39.17 2.18

0 2.18 8.39

0

0 0

4.14

x(-0.0025)

2

-(-0.0075)

2

x10

9

+

x(0.0025)

2

-(-

0.0025)

2

x10

9

26.38 7.58

9.54

7.58 11.07

3.78

9.54 3.78

9.12

+

17.11 9.38 -

6.65 9.38 17.11 -6.65

-6.65 -6.65

10.27

x(0.0075)

2

-(0.0025)

2

x10

9

1/2

+ 1/2

Bij

=

-9.79 -0.55 -

1.66

-0.55 2.1 -1.66

-1.66 -1.66 3.6

x 10

5

Pa-

m2

Dij = 1/3

39.17 2.18

0 2.18 8.39

0

0 0

4.14

x(-0.0025)

3

-(-0.0075)

3

x10

9

+

x(0.0025)

3

-(-

0.0025)

3

x10

9

26.38 7.58

9.54

7.58 11.07

3.78

9.54 3.78

9.12

+

17.11 9.38 -

6.65 9.38 17.11 -6.65

-6.65 -6.65

10.27

x(0.0075)

3

-(0.0025)

3

x10

9

1/3

+ 1/3

7.88 1.61 -0.79

4.89 3.53 -

0.85

-0.79 -0.85

2.03

Dij

=

x 10

3

Pa-

m3

19

1.45 -1.43 11.77

41.33 9.57

1.45

9.57 18.29 -1.43

-9.79 -0.55 -

1.66

-0.55 2.1 -

1.66

-1.66 -1.66 3.6

x

10

6

x

10

5

-9.79 -0.55 -

1.66

-0.55 2.1 -

1.66

-1.66 -1.66 3.6

x

10

5

7.88 1.61 -0.79

4.89 3.53 -

0.85

-0.79 -0.85

2.03

x 10

3

=

-

17.2

90.7

39.9

-

56.3

-

4415.2

-

2936.5

m/m

1/m

x

10

6

30

0

top

-

17.2

90.7

39.9

+ (-0.025)

-

56.3

-4415.2

-2936.5

=

-17.06

101.8

47.24

x 10

-

6

30

0

top

30 deg

ply

26.38 7.58 9.54

7.58 11.07 3.78

9.54 3.78 9.12

=

x

10

9

-17.06

101.8

47.24

x 10

-6

=

77.2

65.29

117.6 x 10

4

Pa

Mid-plane strain, curvature

Global strains

Global stress

The global strains and stress in the 30 ply at the top surface

A

B

20

The local strains and stress in the 30 ply at the top surface

=

0.75 0.25 0.866

0.25 0.75 -

0.866

-0.433 0.433 0.5

-17.06

101.8

47.24

x 10

-

6

=

53.56

31.17

75.08

x 10

-

6

0.75 0.25 0.866

0.25 0.75 -

0.866

-0.433 0.433 0.5

=

77.2

65.29

117.6 x 10

4

Pa

=

143.9

50.9

50.14

x 10

4

Pa

Local stress

Global strains

This process can be repeated for middle and bottom surface for 0

0

and -45

0

plies

C

D

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Wind Effects On Structures: Five Days Training Programme OnDocument2 pagesWind Effects On Structures: Five Days Training Programme OnPravinKulkarniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Smal Blade Fatigue Analysis Revised 12dec2016 PKDocument50 pagesSmal Blade Fatigue Analysis Revised 12dec2016 PKPravinKulkarniNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Smal Blade Fatigue Analysis Revised 14dec2016 PKDocument50 pagesSmal Blade Fatigue Analysis Revised 14dec2016 PKPravinKulkarniNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Cohesive Material PropDocument24 pagesCohesive Material PropPravinKulkarniNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Wind Turbine Composite Blade Fatigue Analysis Using Wind Load Prediction - Published PaperDocument26 pagesWind Turbine Composite Blade Fatigue Analysis Using Wind Load Prediction - Published PaperPravinKulkarniNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Wind Turbine Composite Blade Fatigue Analysis Using Wind Load Prediction - Published PaperDocument26 pagesWind Turbine Composite Blade Fatigue Analysis Using Wind Load Prediction - Published PaperPravinKulkarniNo ratings yet

- Wind Turbine Composite Blade Fatigue Analysis Using Wind Load Prediction - Published PaperDocument26 pagesWind Turbine Composite Blade Fatigue Analysis Using Wind Load Prediction - Published PaperPravinKulkarniNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Formula Derived Physical QuantityDocument6 pagesFormula Derived Physical QuantityPravinKulkarniNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Getting Started With DockerDocument8 pagesGetting Started With DockerdenisaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Blade Material Properties - OrthoDocument3 pagesBlade Material Properties - OrthoPravinKulkarniNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- FatigueDocument116 pagesFatigueSezgin BayrakNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- FatigueDocument116 pagesFatigueSezgin BayrakNo ratings yet

- BEM Method For Wind Turbine Blade AnalysisDocument21 pagesBEM Method For Wind Turbine Blade AnalysisPravinKulkarniNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- John Brown Background EssayDocument2 pagesJohn Brown Background Essayapi-315671250No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Dgcis Report Kolkata PDFDocument12 pagesDgcis Report Kolkata PDFABCDNo ratings yet

- Cruise Ship Its Anatomy Facilities and ADocument14 pagesCruise Ship Its Anatomy Facilities and AAhmad MuhajirNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Marvel EncyclopediaDocument7 pagesMarvel EncyclopediaKris Guillermo25% (4)

- List of Compositions by ChopinDocument16 pagesList of Compositions by Chopindamdidam1No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Philippine AirlinesDocument3 pagesPhilippine AirlinesDyann GarciaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- QMLDocument410 pagesQMLMani Rathinam RajamaniNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- HP 319Document14 pagesHP 319Keenan HydeNo ratings yet

- Asp Et Opacification Digestive Tim 2Document56 pagesAsp Et Opacification Digestive Tim 2Micuss La Merveille BoNo ratings yet

- Year 4 Optional Maths SAT Paper ADocument18 pagesYear 4 Optional Maths SAT Paper Apace_saNo ratings yet

- Train To PakistanDocument7 pagesTrain To Pakistanvineela_13120% (1)

- Essl Connection Diagram For AllDocument5 pagesEssl Connection Diagram For Allpushkar.mulayNo ratings yet

- Low Anode 2Document3 pagesLow Anode 2dusan1962No ratings yet

- Sesión 14 Grupo Caso Familia Fundamentos de MercadeoDocument10 pagesSesión 14 Grupo Caso Familia Fundamentos de MercadeoJoe BalenciagaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Devoir Anglais 4AM4.5 T1 2015Document3 pagesDevoir Anglais 4AM4.5 T1 2015boutkhilNo ratings yet

- IC-ON-LINE - CN dm0365r 44840Document20 pagesIC-ON-LINE - CN dm0365r 44840MoscandoNo ratings yet

- Newcastle-327 Hatil FurnitureDocument1 pageNewcastle-327 Hatil FurnitureARS KHANNo ratings yet

- Two-Step Story Problems Freebie: by Jan GervaisDocument10 pagesTwo-Step Story Problems Freebie: by Jan Gervaisapi-311208292No ratings yet

- 493 - Reported Speech Test b1 Grammar ExercisesDocument3 pages493 - Reported Speech Test b1 Grammar ExercisesmariNo ratings yet

- ReviewerDocument93 pagesReviewerGeorgette Marie B. Tejada50% (2)

- Networks-Lab 6632853 PowerpointDocument22 pagesNetworks-Lab 6632853 PowerpointVivek Kumar SinhaNo ratings yet

- Turandot Study GuideDocument37 pagesTurandot Study GuideBoran SavranNo ratings yet

- City of DijishyDocument59 pagesCity of DijishyPeter Bearden100% (8)

- Australian Law IndexDocument34 pagesAustralian Law IndexBashNo ratings yet

- Crop ImprovementDocument7 pagesCrop Improvementshahena sNo ratings yet

- TVXCBCVBDocument6 pagesTVXCBCVBElaine Iris AbastaNo ratings yet

- Inspectors and Authorities MannualDocument20 pagesInspectors and Authorities MannualHenry DengNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Don Featherstone Colonial RulesDocument2 pagesDon Featherstone Colonial RulesA Jeff ButlerNo ratings yet

- Diet Analysis MyPlate TableDocument3 pagesDiet Analysis MyPlate TableAde AzikweNo ratings yet