Professional Documents

Culture Documents

PQI

Uploaded by

Bit Squad100%(1)100% found this document useful (1 vote)

1K views8 pagesCase analysis of PQI: Management of Suppliers

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCase analysis of PQI: Management of Suppliers

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views8 pagesPQI

Uploaded by

Bit SquadCase analysis of PQI: Management of Suppliers

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 8

PQI: Management of suppliers

Global Sourcing and Supply Chain Management

Group N 6:

Pranav Goyal

Patricia Guht

Michaela Novotna

Margarida Tenente

Case overview

The memory industry

Power Quontient International Co. Ldt (PQI):

Taiwan-based electronics company, specialized in memory manufacturing

Established in 1997

2008: PQI was ranked the 10th largest supplier in DRAM modules, flash cards and

USB flash drives in the world

Manufacturing plants in Taiwan and Suzhou in China

Subsidiaries in the US, Netherlands, Japan, Korea, Hong Kong and China more than

900 employees around the world

PQIs purchasing department is divided into general purchasers (70 people) and

strategic purchasers (20 people)

Suppliers are classified within Tier 1, Tier 2 and Tier 3 groups

.

Classification of suppliers

Transaction costs and risk

Transaction costs Risk

Tier 1 Suppliers

- Global

- Strategic partners

search and information cost

bargaining cost (economies of

scale)

policing and enforcement cost

Higher risk suppliers are

strategically important need

for close relationships

Tier 2 Suppliers

-Regional

-Standard products

search and information cost

bargaining cost

policing and enforcement cost

Lower risk

Tier 3 Suppliers

-Local

-Low-end/structural

components

search and information cost

bargaining cost

policing and enforcement cost

Highest transaction cost

Responsiveness

- Suppliers who can work fast

will become long-term strategic

partners

Protection of IP

Analysis of the biannual score sheets

Multiple tier 3 suppliers who were strong in technical and commercial

performance received average scores

PQI had not reviewed its supplier evaluation process

.

The evaluation TODAY:

The analysis is the sum of points for each criteria

Same criteria for all suppliers

Possible trade off between being fast and responsive

vs. cost effective (lower prices)

.

Recommendations

Assign different weights to each criteria according to the importance

of the criteria to PQI more quantitative approach

Group the criteria into different categories

specific to the suppliers business:

Cost: 5-6,

Responsiveness: 9-13,

Good Relationship with customer: 14-16,

Quality control: 17-19 & 7

Technological capacity: 20, 8, 1-4.

Attribute average points in those categories

Based on the importance for PQI, a decision on suppliers can be taken

Sharing of results with suppliers

The impact on management

Results should be shown and discussed with suppliers

Sharing develops two-way mutually beneficial relationships

Reduces risk and suppliers realize new value

Motivates suppliers to work in the direction of PQIs ultimate strategy

Expands the scope of interaction with key suppliers

Would help supplier know about the expectations of the PQI

.

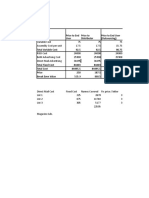

Choosing a supplier using established method with

weights for grouped criteria

Order involves die casting Tier 3 suppliers (standardized process)

Supplier A B C

Score

Choose supplier C

Important criteria:

Responsiveness rush order

Lower volume less emphasis on cost

Thank you for your attention.

You might also like

- PQI: Management of Suppliers: Global Sourcing and Supply Chain ManagementDocument8 pagesPQI: Management of Suppliers: Global Sourcing and Supply Chain ManagementIsrar AhmedNo ratings yet

- PGP12101 B Akula Padma Priya DADocument20 pagesPGP12101 B Akula Padma Priya DApadma priya akulaNo ratings yet

- PQI Management, Group 5, Section BDocument6 pagesPQI Management, Group 5, Section BPrabhavShuklaNo ratings yet

- Innovation Simulation: Breaking News: HBP Product No. 8678Document9 pagesInnovation Simulation: Breaking News: HBP Product No. 8678Karan ShahNo ratings yet

- Philips Lighting CAB Eden GardensDocument5 pagesPhilips Lighting CAB Eden GardensVinayNo ratings yet

- Atlantic Computer - A Bundle of Pricing OptionsDocument6 pagesAtlantic Computer - A Bundle of Pricing OptionsAashi JainNo ratings yet

- MDCM Case Write UpDocument16 pagesMDCM Case Write UpKurt MarshallNo ratings yet

- Group5 - B 3rd CaseDocument2 pagesGroup5 - B 3rd CaseRisheek SaiNo ratings yet

- Does IT Payoff? Strategies of Two Banking Giants: Submitted By: Group 4, Section BDocument5 pagesDoes IT Payoff? Strategies of Two Banking Giants: Submitted By: Group 4, Section BNeha Bhomia GuptaNo ratings yet

- EFI Case - Mukund - Kabra - Sales ManagementDocument2 pagesEFI Case - Mukund - Kabra - Sales ManagementMukund KabraNo ratings yet

- BM - Group - Num - 8Document8 pagesBM - Group - Num - 8Suraj GavhaneNo ratings yet

- DocDocument3 pagesDocAbbas Raza ShafqatNo ratings yet

- Section B Group 7 CyworldDocument12 pagesSection B Group 7 CyworldlaxmanNo ratings yet

- Module 01 Class 01: Introduction To SCMDocument10 pagesModule 01 Class 01: Introduction To SCMVINAYAKA G P MECH.No ratings yet

- Case Analysis - Michigan Manufacturing CorporationDocument2 pagesCase Analysis - Michigan Manufacturing CorporationhemanthillipilliNo ratings yet

- Integrated L & SCM Case StudyDocument21 pagesIntegrated L & SCM Case Studyrahul_thorat01No ratings yet

- Avari Ramada Hotel Case Study ReportDocument6 pagesAvari Ramada Hotel Case Study ReportAvishek Hota100% (1)

- Case MethodDocument10 pagesCase MethodEka Moses MarpaungNo ratings yet

- A Cat - Corp - Case - 401508007Document10 pagesA Cat - Corp - Case - 401508007akshay kushNo ratings yet

- Metro Cash & CarryDocument9 pagesMetro Cash & CarrySaurav SanganeriaNo ratings yet

- Case Analysis: Netflix: Pricing Decision 2011: Group 3Document7 pagesCase Analysis: Netflix: Pricing Decision 2011: Group 3vedant thakreNo ratings yet

- Merloni Elettrodomestici Spa: The Transit Point Experiment: Supply Chain ManagementDocument5 pagesMerloni Elettrodomestici Spa: The Transit Point Experiment: Supply Chain ManagementSaumya GautamNo ratings yet

- Callaway Golf Company StrategyDocument2 pagesCallaway Golf Company StrategySam Narjinary0% (1)

- Dwo PHD01003 Harshad Savant Term2 EndtermDocument8 pagesDwo PHD01003 Harshad Savant Term2 EndtermHarshad SavantNo ratings yet

- SCM Karnataka Engineering CaseDocument6 pagesSCM Karnataka Engineering CaseJSNo ratings yet

- Tale of Two Companies, Case SummaryDocument3 pagesTale of Two Companies, Case Summaryshershah hassan0% (1)

- Prithvi Electricals B2B Motor StrategyDocument4 pagesPrithvi Electricals B2B Motor StrategyOishik BanerjiNo ratings yet

- KVA Anusha - PGP12021 - BADocument8 pagesKVA Anusha - PGP12021 - BAAditi Pareek100% (1)

- Eastman Kodak CompanyDocument9 pagesEastman Kodak CompanyArveen KaurNo ratings yet

- Case 4.1 - Group 3Document10 pagesCase 4.1 - Group 3Trần Nguyễn Thanh ThoaNo ratings yet

- MGCR352-004 - Fall 2018Document6 pagesMGCR352-004 - Fall 2018Burak SoydanNo ratings yet

- Weikang Case AnalysisDocument11 pagesWeikang Case AnalysisVamsi GunturuNo ratings yet

- Strategic Management ProjectDocument9 pagesStrategic Management Projectnaeem sarwarNo ratings yet

- Barilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryDocument3 pagesBarilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryRichaNo ratings yet

- Ingersoll-Rand (A) : Managing Multiple Channels: 1985Document5 pagesIngersoll-Rand (A) : Managing Multiple Channels: 1985miteshgajjarNo ratings yet

- RCF's Supply Chain Management StrategiesDocument24 pagesRCF's Supply Chain Management Strategiesmalik_samnani100% (1)

- Case Study On Convertible Alternative Reference Securities: Xlri-Pgcbm-37Document7 pagesCase Study On Convertible Alternative Reference Securities: Xlri-Pgcbm-37Senthil KumarNo ratings yet

- PKCLDocument11 pagesPKCLonkar joshi100% (1)

- 1Document4 pages1Mayank RajNo ratings yet

- BM Kurlon CaseDocument6 pagesBM Kurlon CaseArun A RNo ratings yet

- Loctite Case StatsDocument8 pagesLoctite Case StatsBharat SinghNo ratings yet

- Movie Rental Business PDFDocument6 pagesMovie Rental Business PDFAmir khanNo ratings yet

- 4 - Supply Chain Coordination and Contracts in The Sharing Economy - A Case Study at CargoDocument25 pages4 - Supply Chain Coordination and Contracts in The Sharing Economy - A Case Study at CargoAbhishekRathourNo ratings yet

- Reinventing Officer's Choice Whisky: Spoiled For Choice: Group 3, Section BDocument4 pagesReinventing Officer's Choice Whisky: Spoiled For Choice: Group 3, Section BDeepu TiwariNo ratings yet

- Cashlet 4Document3 pagesCashlet 4Vinay SharmaNo ratings yet

- Microsoft Slide Part 1Document13 pagesMicrosoft Slide Part 1Camilla CenciNo ratings yet

- CASE STUDY ANALYSIS: LONDON OLYMPICS 2012 TICKET PRICINGDocument6 pagesCASE STUDY ANALYSIS: LONDON OLYMPICS 2012 TICKET PRICINGSwati Babbar0% (1)

- Ingersoll Rand Sec B Group 1Document8 pagesIngersoll Rand Sec B Group 1biakNo ratings yet

- Reinventing Best Buy Through Customer-Centric StrategyDocument4 pagesReinventing Best Buy Through Customer-Centric StrategyShubham ThakurNo ratings yet

- Rupesh Kumar Gupta-1421229 (Conglomerate Inc Case Study)Document8 pagesRupesh Kumar Gupta-1421229 (Conglomerate Inc Case Study)RupeshGupta50% (2)

- InfoTech CorporationDocument11 pagesInfoTech CorporationSomdipta MaityNo ratings yet

- HasbroPOX (A)Document6 pagesHasbroPOX (A)Parnamoy DuttaNo ratings yet

- Li & FungDocument30 pagesLi & FungShiva RamNo ratings yet

- DPS 304 Sourcing Strategies & PoliciesDocument34 pagesDPS 304 Sourcing Strategies & PoliciesSehar AdilNo ratings yet

- Profile: Muhammad Rahies KhanDocument16 pagesProfile: Muhammad Rahies KhanHassan AliNo ratings yet

- MODULE-II Sourcing ManagementDocument14 pagesMODULE-II Sourcing ManagementumeshNo ratings yet

- Supplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLDocument38 pagesSupplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLsrkadaliNo ratings yet

- Computational ThinkingDocument10 pagesComputational ThinkingHà Vi ĐinhNo ratings yet

- Procurement: EIN 5346 Logistics EngineeringDocument65 pagesProcurement: EIN 5346 Logistics EngineeringGayatri NaiduNo ratings yet

- OpMan - Supply ChainDocument10 pagesOpMan - Supply ChainKaila Mae Tan DuNo ratings yet

- Supply ChainDocument2 pagesSupply ChainBit SquadNo ratings yet

- Zappos Case StudyDocument11 pagesZappos Case StudyBit Squad100% (3)

- PQIDocument8 pagesPQIBit Squad100% (1)

- Make or BuyDocument11 pagesMake or BuyBit SquadNo ratings yet

- MR Bengal Sponsorship ProposalDocument15 pagesMR Bengal Sponsorship ProposalJoy SinhaNo ratings yet

- Samsung Mobile Application Distribution AgreementDocument14 pagesSamsung Mobile Application Distribution AgreementBen EdelmanNo ratings yet

- Strategic Management The New Challenge of The New CenturyDocument3 pagesStrategic Management The New Challenge of The New CenturyElla100% (3)

- Introduction To Business AdvisorDocument12 pagesIntroduction To Business Advisorshanza.rdnNo ratings yet

- Sugar Free CaseDocument14 pagesSugar Free CaseVimal Singh ChauhanNo ratings yet

- Insura CoDocument151 pagesInsura CoSiyuan SunNo ratings yet

- Consumer Behaviour and Impulsive Buying BehaviourDocument38 pagesConsumer Behaviour and Impulsive Buying BehaviourNeeraj Purohit100% (3)

- Know Your Customer for Effective AdvertisingDocument24 pagesKnow Your Customer for Effective AdvertisingMass Comm AssignmentsNo ratings yet

- Form 4 Pob - Scheme of Work - Term 3Document9 pagesForm 4 Pob - Scheme of Work - Term 3pratibha jaggan martinNo ratings yet

- Chap 11Document8 pagesChap 11Emmanuel MariaNo ratings yet

- Digital Media Lead Application Pack PDFDocument6 pagesDigital Media Lead Application Pack PDFaasim kNo ratings yet

- ME Module 3Document51 pagesME Module 3Shreevas NandanNo ratings yet

- Bharat Engineering Works Limited Is A Major Manufacturer of IndustrialDocument2 pagesBharat Engineering Works Limited Is A Major Manufacturer of IndustrialSatish NagireddyNo ratings yet

- Safexpress 160626045039Document22 pagesSafexpress 160626045039SahilDhimanNo ratings yet

- ERP Book Excerpts Zaveri RevisedDocument116 pagesERP Book Excerpts Zaveri RevisedMuthu Kumaran100% (2)

- SWOT AnalysisDocument3 pagesSWOT AnalysisScott James67% (3)

- 11 Rachel PedersenDocument14 pages11 Rachel PedersenNanang Warno100% (18)

- Online Advertising BLUE BOOK: The Guide To Ad Networks & ExchangesDocument28 pagesOnline Advertising BLUE BOOK: The Guide To Ad Networks & ExchangesmThink100% (1)

- Business Plan Pizza DonutDocument83 pagesBusiness Plan Pizza DonutBlackChemistry Guipetacio100% (1)

- Principles of Marketing ModuleDocument75 pagesPrinciples of Marketing ModuleJecelle BalbontinNo ratings yet

- 2nd Quarter Exam EntrepreneurshipDocument5 pages2nd Quarter Exam Entrepreneurshipjeo nalugon100% (1)

- QB BBA Operations ManagementDocument23 pagesQB BBA Operations ManagementFuad100% (2)

- q4 Marketing Plan Principles of MarketingDocument3 pagesq4 Marketing Plan Principles of MarketingCharlene EbordaNo ratings yet

- Gapped SentencesDocument3 pagesGapped Sentencesinesregueira8958100% (1)

- Marketing Plan (Autosaved)Document19 pagesMarketing Plan (Autosaved)JayanneNo ratings yet

- This Is MarketingDocument201 pagesThis Is Marketingmarketing joviste100% (21)

- Avt Brand 1dfdfdfDocument100 pagesAvt Brand 1dfdfdfRohanPuthalathNo ratings yet

- Agricultural Marketing Handout Final Ready To PrintDocument56 pagesAgricultural Marketing Handout Final Ready To Printisohunexs67% (3)

- Udah Bener'Document4 pagesUdah Bener'Shafa AzahraNo ratings yet

- ADIDAS and Its Promotional StrategiesDocument17 pagesADIDAS and Its Promotional StrategiesMythil Meshram100% (1)