Professional Documents

Culture Documents

African Minerals LTD

Uploaded by

hoangtien1991Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

African Minerals LTD

Uploaded by

hoangtien1991Copyright:

Available Formats

IRON ORE PROCESSING

STAGE 1B

AT

AFRICAN MINERALS LTD.,

TONKOLILI

Overview of Presentation

Industry Overview

Process Overview

Iron ore Process

Project Overview

System Architecture

Softwares used

PLC Code Programming Structure

SCADA

Industry Overview

African Minerals has been active in Sierra

Leone since 1996.

Phase I production capacity increased from

15Mtpa to 20Mtpa and low cash costs expected

at under $30/t..

Industry Overview

Established in 1991 .

Mining industry experts - for the delivery of turnkey

Mining process projects.

AML Plant total designed by Ausenco.

Industry Overview

LV Systems

Instrumentation

Control Systems

Plant Management Systems

Support & Maintenance

Plant Installations

What is Iron Ore??

Iron ore is any rock or mineral from which

iron can economically be extracted form

of iron oxides such as magnetite.

Ore contain between 25% to 60% iron.

Iron Ore Process

overview

Iron Ore Process

ROM bin continuous level transmitter Lo Level to

activate Green light for front end loaders to fill the

ROM bin.

Hi Level to activate Red light for front end loaders to stop

filling the ROM bin

Apron Feeder

Speed Controlled by WIC in Automatic mode, or Operator set

point in Manual

Roller Screen

Roller Screen Contain 8 motors. If any motor stopped due to

Motor jam. Then all 8 motors stop and wait 5 sec Restart the

Roller in Reverse. Run the Roller in Reverse for 10 seconds

Stop the Roller for 5 seconds. Start the Roller Forward. All the

operation in Auto mode

Iron Ore Process

Over Land Conveyer after primary crushed iron

ore Transfer to Scrubber by using over land

conveyer.

(2.5 Km Power Regeneration Drive)

The Over Land Conveyer generated

1 Mw Power.

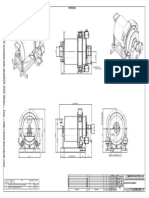

DOUBLE ROLLS CRUSHER

The drive cannot be started/stopped individually from the

PCS. The Crusher Drives Will Start and Stop as One Drive

Iron Ore Process

Scrubber Feed Diverter Chute

Move to Dump position when either Scrubber, CV003,

Screen1 or Process water pumps any one stop Diverter Chute

move to Dump position

Iron Ore Process

Crushed ore delivered from the

overland conveyor discharges into

the scrubber where process water is

added. The ore is scrubbed and clay

minerals are washed from the ore

surface before discharging from the

scrubber via the discharge trammel,

which has a screen aperture size of

32mm. The trammel oversize

material discharges to the cone

crushing circuit while the undersize

material gravitates to the coarse

screen.

Scrubber

Iron Ore Process

Tailing Thickener

The coarse screen (8mm aperture) oversize discharges onto the

lump product conveyor, and undersize slurry gravitates to the

fines dewatering cyclones feed hopper. Slurry from the fines

dewatering cyclones hopper is pumped in two parallel closed

circuits of feed pumps, dewatering cyclones and dewatering

screens. Overflow from the cyclones discharges to the tailings

thickener.

Thickener under flow

There are three thickener underflow pumps, each with

dedicated discharge lines to the tailings hopper. To enable

recycling of slurry back to the thickener, when required, two

of the pumps are provided with recycle lines to the thickener

feed tank.

All three of the pumps can be variable speed controlled and

have dedicated Flow & Pressure Cascade control loops. The

number of pumps required to run at any one time will depend

upon the ore type being fed into the process. More pumps will

be required to run if the ore contains a large amount of fine

material.

Iron Ore Process

From Scrubber over Size ore going to

Cone Crusher and Normal Size go to

Dry Screen. Cone Crusher Crushed the

ore and send to Dry Screen. After

Screen Lump Ore transfer to Lump

Product House.

Cone Crusher

Controlled by vendor supplied LCP but remotely started and

stopped from the PCS. The amount of cone crushers to run

will be determined and selected by the operator based on the

type and amount of ore being fed to the process. The cone

crusher is selected to Auto on the LCP if it is required to start

and stop remotely.

Iron Ore Process

From Product House to Stock Dump

yard going through Stackers

(Lumps & Fines).

Stackers

The finished Iron Ore transferred

to Port by Train.

And Fine direct Separated from

Scrubber Outlet its transfer to fine

Product house.

IRON ORE PROCESSING

STAGE 1B

AT

AFRICAN MINERALS LTD.,

TONKOLILI

The Aim of This Project was :-

1. To reduce the Time and Logistic

This Process plant to increase in production

1800Tph.

Overall increase in capacity 15Mtpa to

20Mtpa .

System Architecture

This project utilizes Schneider-Quantum-140 CPU

652 60 02.40, No- 4 PLCS

ModiconM340-BMX P34 2020 02.10, No-4 PLCs

Software-Unity Pro XL V 6.0,Vijeo Citect 7.2,

Pro Soft V 2.3.2.2, Power Suite v 2.6.1.

System Architecture

FO

Primary Crusher

Area

Dry Screen Area

Raw Water Area

Jozi Power Area

Server Room

EH

Op station 2 Op station 1 Engg station

Scrubber Area

Scrubber Area PLC Configuration

Schneider-Quantum-140 CPU 652 60 02.40, No- 2 PLCS

PLC-1

Digital IP-2M-64 I/O

Analog IP-2M-32 I/O

Digital OP-1M-32 I/O

Analog OP-2M-8 I/O

PLC-11

Digital IP-2M-64 I/O

Analog IP-2M-32 I/O

Digital OP-1M-32 I/O

Analog OP-3M-12 I/O

Dry screen & Primary Area PLC Configuration

Schneider-Quantum-140 CPU 652 60 02.40, No- 1 PLC

PLC-2

Digital IP-4M-128 I/O

Analog IP-1M-16 I/O

Digital OP-1M-32 I/O

Analog OP-1M-4 I/O

Schneider-Quantum-140 CPU 652 60 02.40, No- 1 PLC

PLC-4

Digital IP-4M-128 I/O

Analog IP-1M-16 I/O

Digital OP-1M-32 I/O

Analog OP-1M-4 I/O

Jozi power & Raw water Area PLC Configuration

ModiconM340-BMX P34 2020 02.10, No- 1PLC

PLC-96

Digital IP-2M-32 I/O

Analog IP-3M-12 I/O

Digital OP-1M-16 I/O

Analog OP-1M-4 I/O

ModiconM340-BMX P34 2020 02.10, No- 1PLC

PLC-91

Digital IP-1M-16 I/O

Analog IP-2M-8 I/O

Digital OP-1M-16 I/O

Analog OP-1M-4 I/O

ProfiBus Communication module

ProfiBus Communication module

Supporting for Schneider PLCs

Baud Rate Support Up to 12,000 K Bit/Sec

ProSoft Configuration

ProfiBus Communication

ProSoft Description

TeSys T Protection Relay

Spider controller for Scrubber

Siemens CP 342-5 for Cone Crusher

Control Techniques Unidrive SP for VSDs

This all GS* files

All the above GS* files Communicated with Schneider PLCs

PLC Programming Structure

Sequence logic was distributed in different Section

known as the.

Analogs:A1061LIT6102.

PID Loops:A1051FIC5126.

Drives:A1051PU15.

Valves:A1051XV5145.

E.g. Analogs:A1061LIT6102

A1061- Area, LIT- Instrument, 6102- Number

PLC Programming Structure

Sequences are known as the -

Sequence:SQPU038_STT.

Sequence:SQPU038_STP.

E.g. Sequence:SQPU038_STT

SQ-Sequence, PU038-Pump Number, STT-Start

PLC Code Structure

PLC Code for Analogs

PLC Code for PID Loops

PLC Code for Drives

PLC Code for Valves & Sequences

PLC Code for inter PLC communication

BIT9 A1012CV002BRS2FLT

BIT11 A1012CV002BRS6A

BIT4 A1012CV002BDS8A

BIT7 A1021SB001_RUNUP

BIT12 A1012ZSH1282

BIT14 A1012ZSH1284A

BIT6 A1012CV002BDS10A

BIT1 A1012CV002BDS5A

BIT10 A1012CV002BRS5A

BIT3 A1012CV002BDS7A

BIT15 A1012ZSH1284B

BIT13 A1012ZSH1283

BIT5 A1012CV002BDS9A

BIT2 A1012CV002BDS6A

BIT8 A1012CV002BRS2RLS

BIT0 %S6 OUT

.31

BIT_TO_WORD

16

BIT9 A1021PU088_RUNUP

BIT11 A1021PU089_RUNUP

BIT4 A1022CR003_RUN

BIT7 A1022CR004_RUNUP

BIT12 A1021PU090_RUN

BIT14 A1012ZSO1293A

BIT6 A1022CR004_RUN

BIT1 A1012ZSO1285

BIT10 A1021PU089_RUN

BIT3 A1012ZSO1292A

BIT15 A1012ZSO1294A

BIT13 A1021PU090_RUNUP

BIT5 A1022CR003_RUNUP

BIT2 A1012ZSO1291A

BIT8 A1021PU088_RUN

BIT0 A1012ZSH1284C OUT

.32

BIT_TO_WORD

20

REAL_IN

BOOL3_IN

BOOL4_IN

BOOL1_IN

BOOL2_IN

INT_IN

PUB_OUT PLC1_EGD

FBI_230

COMMS_PUB

22

BIT9 A1022CV003_RUNDN

BIT11 A1072CV010_SEQSTP_TPLC2

BIT4 A1072ST002_AUTOSTT_HMI_TPLC2

BIT7 A1022CV003_SEQRDY

BIT12

BIT14 A1072ST002_AUTOSTP_TPLC2

BIT6 A1072CV010_AUTO_TPLC2

BIT1 A1072ST002_BELT_STT_TPLC2

BIT10 A1072CV012_SEQSTP_TPLC2

BIT3 A1072CV010_SEQSTT_TPLC2

BIT15 A1023CV006_RUNUP

BIT13 A1072ST002_BELT_STP_TPLC2

BIT5 A1072CV012_AUTO_TPLC2

BIT2 A1072CV012_SEQSTT_TPLC2

BIT8 A1022CV003_RUNUP

BIT0 A1072ST002_AUTOSTT_TPLC2 OUT

.1

BIT_TO_WORD

17

BIT9 A1021FIC2102_LLA

BIT11 A1061PU056_RUNUP

BIT4 A1021SC001_RUNDN

BIT7 A1022CV003_RUN

BIT12

BIT14

BIT6 A1061PU045_SEQSTP_TPLC11

BIT1 A1023CV006_SEQRDY

BIT10 A1061PU001_RUNUP

BIT3 A1021SC001_RUNUP

BIT15

BIT13

BIT5 A1061PU020_SEQSTP_TPLC11

BIT2 A1021SC001_SEQRDY

BIT8 A1021SC001_RUN

BIT0 A1023CV006_RUNDN OUT

.2

BIT_TO_WORD

21

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

CH16

CH17

CH18

CH19

CH20

CH21

CH22

CH23

CH24

CH25

CH26

CH27

CH28

CH29

CH30

CH31

CH32

INT_Array

FBI_231

PUB_INT

18

CH1 TMWG

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

CH16

CH17

CH18

CH19

CH20

CH21

CH22

CH23

CH24

CH25

CH26

CH27

CH28

CH29

CH30

CH31

CH32

REAL_Array

FBI_232

PUB_REAL

19

Publ i sh Data

PLC Code for inter PLC communication

Data_IN

INT_CH_3

INT_CH_31

INT_CH_28

INT_CH_22

INT_CH_25

INT_CH_19

INT_CH_16

INT_CH_13

INT_CH_7

INT_CH_10

INT_CH_4

INT_CH_1 A1022WQIT2229_RAWPV

INT_CH_32

INT_CH_29

INT_CH_26

INT_CH_23

INT_CH_17

INT_CH_20

INT_CH_14

INT_CH_11

INT_CH_8

INT_CH_2

INT_CH_5

INT_CH_27

INT_CH_30

INT_CH_24

INT_CH_21

INT_CH_18

INT_CH_12

INT_CH_15

INT_CH_9

INT_CH_6

FBI_1953

COMMS_INT

4

RSTI

IP3 2

IP4 22

IP1 10

Chn1Data PLC2_EGD

StartAddress 1200

IP2 0

Data PLC2_Data

Comms_Dest PLC2_COMMS

Al armChn1 PLC1R2_CommsChn1A

Al armChn2 PLC1R2_CommsChn2A

Al arm PLC2_CommsA

FBI_1927

COMMS_SELECT

1

PUB_OUT

REAL_CH_3

REAL_CH_31

REAL_CH_28

REAL_CH_22

REAL_CH_25

REAL_CH_19

REAL_CH_16

REAL_CH_13

REAL_CH_7

REAL_CH_10

REAL_CH_4

REAL_CH_1 A1023WIT2329_PV_FPLC2

REAL_CH_32

REAL_CH_29

REAL_CH_26

REAL_CH_23

REAL_CH_17

REAL_CH_20

REAL_CH_14

REAL_CH_11

REAL_CH_8

REAL_CH_2 A1023WIT2339_PV_FPLC2

REAL_CH_5

REAL_CH_27

REAL_CH_30

REAL_CH_24

REAL_CH_21

REAL_CH_18

REAL_CH_12

REAL_CH_15

REAL_CH_9

REAL_CH_6

FBI_1952

COMMS_REAL

3

Data_IN

BOOL_CH_3 A1072CV010_RUN_Comms

BOOL_CH_31

BOOL_CH_28

BOOL_CH_22

BOOL_CH_25 A1022CV004_RUN

BOOL_CH_19 A1021SC001_SEQSTT

BOOL_CH_16 A1022CV003_SEQSTT

BOOL_CH_13 A1072ST002_ILOC_FPLC2

BOOL_CH_7 A1072CV010_RUNDN_FPLC2

BOOL_CH_10 A1072CV012_RUNDN_FPLC2

BOOL_CH_4 A1023CV006_SEQSTT

BOOL_CH_1 PLC2_Watchdog

BOOL_CH_32

BOOL_CH_29

BOOL_CH_26

BOOL_CH_23

BOOL_CH_17 A1022CV003_SEQSTP

BOOL_CH_20 A1021SC001_SEQSTP

BOOL_CH_14 A1072ST002_IRDY_FPLC2

BOOL_CH_11 A1072CV012_RUNUP_FPLC2

BOOL_CH_8 A1072ST002_IRUN_FPLC2

BOOL_CH_2 A1071CV007_RUN_Comms

BOOL_CH_5 A1023CV006_SEQSTP

BOOL_CH_27

BOOL_CH_30

BOOL_CH_24

BOOL_CH_21

BOOL_CH_18 A1021SC001_AUTO_FPLC2

BOOL_CH_12 A1072CV012_SEQRDY_FPLC2

BOOL_CH_15 A1022CV003_AUTO_FPLC2

BOOL_CH_9 A1072CV010_SEQRDY_FPLC2

BOOL_CH_6 A1023CV006_AUTO_FPLC2

FBI_1954

COMMS_BOOL1

5

PLC2 recei ved data

Data_IN BOOL_CH_33

BOOL_CH_34

BOOL_CH_35

BOOL_CH_36

BOOL_CH_37

BOOL_CH_38

BOOL_CH_39

BOOL_CH_40

BOOL_CH_41

BOOL_CH_42

BOOL_CH_43

BOOL_CH_44

BOOL_CH_45

BOOL_CH_46

BOOL_CH_47

BOOL_CH_48

BOOL_CH_49

BOOL_CH_50

BOOL_CH_51

BOOL_CH_52

BOOL_CH_53

BOOL_CH_54

BOOL_CH_55

BOOL_CH_56

BOOL_CH_57

BOOL_CH_58

BOOL_CH_59

BOOL_CH_60

BOOL_CH_61

BOOL_CH_62

BOOL_CH_63

BOOL_CH_64

FBI_1955

COMMS_BOOL2

2

PLC2_Data PLC2_Data PLC2_Data PLC2_Data

Analogs & Drives Popup

Analogs Motors & Pumps Conveyers VSDs

PID Loops

Valves & Sequences

Presentation Prepared By GHT

Thanks for your attendance.

You might also like

- The Vulnerability Economy - Zero-Days, Cybersecurity, and Public PolicyDocument11 pagesThe Vulnerability Economy - Zero-Days, Cybersecurity, and Public PolicyAyejuyole SolaNo ratings yet

- Falk Quadrive Shaft Mounted Drive - Interchange Guide 371810Document12 pagesFalk Quadrive Shaft Mounted Drive - Interchange Guide 371810Anonymous ntE0hG2TPNo ratings yet

- IPJ2400 Version 5 PDFDocument37 pagesIPJ2400 Version 5 PDFRoberto CalderonNo ratings yet

- Amphibious Multipurpose DredgerDocument14 pagesAmphibious Multipurpose DredgerArif Ahmed100% (1)

- Report For 92MW Power Plant of UltratechDocument52 pagesReport For 92MW Power Plant of UltratechNirav Parmar100% (1)

- LP Series Limpsfield Combustion Operating and Maintenance Manual Iss3Document63 pagesLP Series Limpsfield Combustion Operating and Maintenance Manual Iss3hoangtien1991No ratings yet

- Crushing Plant For Sale1Document18 pagesCrushing Plant For Sale1Vicky NonatoNo ratings yet

- Packing List SamplerDocument2 pagesPacking List SamplerJuan Jose Coila P.No ratings yet

- The Frothbuster - A Solution To Frothing Thickeners Authors: Ian Arbuthnot - Outokumpu Technology Pty LTD Carla Kaboth - Normandy Mining LTD (Golden Grove)Document2 pagesThe Frothbuster - A Solution To Frothing Thickeners Authors: Ian Arbuthnot - Outokumpu Technology Pty LTD Carla Kaboth - Normandy Mining LTD (Golden Grove)Víctor SandovskyNo ratings yet

- Multotec Injection Moulded Screening Systems-Digital-4c504Document6 pagesMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoNo ratings yet

- FanSave53 RevDocument48 pagesFanSave53 RevHo Dac ThanhNo ratings yet

- 6040 Wear Chart PDFDocument10 pages6040 Wear Chart PDFAnthony MendoNo ratings yet

- BI6517010001 Procedure To Locate The Soft Spot On Slew Rings On Certain 6040-6090FS Hydraulic Mining ShovelsDocument3 pagesBI6517010001 Procedure To Locate The Soft Spot On Slew Rings On Certain 6040-6090FS Hydraulic Mining ShovelsVictor Marcos BautistaNo ratings yet

- Unidad Hidráulica PF1019Document2 pagesUnidad Hidráulica PF1019Juan Carlos Lopez TorresNo ratings yet

- Waterwell Catalog WebDocument96 pagesWaterwell Catalog WebJuan Carlos Sequeira RoblesNo ratings yet

- Toromocho Project: Minera Chinalco Peru S.ADocument93 pagesToromocho Project: Minera Chinalco Peru S.ALuis Valdez espinozaNo ratings yet

- ZARANDASDocument3 pagesZARANDASRaphael PalaciosNo ratings yet

- Information: Equipment To April, 1999 - Crushers I. Primary CrusherDocument22 pagesInformation: Equipment To April, 1999 - Crushers I. Primary CrusherJose Carlos Garcia MamaniNo ratings yet

- Lubricantes - HPGR StartupDocument1 pageLubricantes - HPGR StartupElios TorreblancaNo ratings yet

- Yakuhin Limeslaker PDFDocument2 pagesYakuhin Limeslaker PDFEly TharNo ratings yet

- SAG Mill ManufacturerDocument2 pagesSAG Mill ManufacturerRodrigo GarcíaNo ratings yet

- Ficha Técnica Panel Solar Jinko 370WpDocument2 pagesFicha Técnica Panel Solar Jinko 370WpAlvaro Trigoso67% (3)

- Probebrochure Rev8Document7 pagesProbebrochure Rev8Matheus TorresNo ratings yet

- Valu King Screen 1Document3 pagesValu King Screen 1RAUL PEREZ NEGREIROSNo ratings yet

- Slurry Pumps MCU Introduction (English)Document33 pagesSlurry Pumps MCU Introduction (English)Jose Antonio RojasNo ratings yet

- New Parts: Item Number Item Name Where Used Price Qty On HandDocument7 pagesNew Parts: Item Number Item Name Where Used Price Qty On HandcarrialdiNo ratings yet

- MultitecDocument96 pagesMultitecarietilang100% (1)

- Improper Crusher Feeding: Jaw CrushersDocument1 pageImproper Crusher Feeding: Jaw CrushersbfygNo ratings yet

- Squat TableDocument1 pageSquat TableTakis RappasNo ratings yet

- Flow Sheet (Solis Egusquiza Ronald)Document83 pagesFlow Sheet (Solis Egusquiza Ronald)Dan PerezNo ratings yet

- Kurva RPM THDDocument3 pagesKurva RPM THDWulan MaharaniNo ratings yet

- Diemme FiltrationDocument8 pagesDiemme FiltrationAbu Fathi Mifth Huda100% (1)

- Cross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4Document4 pagesCross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4raulNo ratings yet

- Grinding Mill DrawingDocument1 pageGrinding Mill DrawingHans ManriqueNo ratings yet

- Lightnin Compact Series MixersDocument21 pagesLightnin Compact Series Mixersmiguel_vera6592No ratings yet

- Tarea 3 - Ejercicio CURVA SDocument2 pagesTarea 3 - Ejercicio CURVA SDaniel Castillo GonzalezNo ratings yet

- Mineralizaciones de Cu de Tipo SkarnDocument10 pagesMineralizaciones de Cu de Tipo SkarnJorge Rios RNo ratings yet

- 15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Document66 pages15 - Load - Construction - Type - Resultado Cabeceras (Area 3000)Juan Jose San Martin AlfaroNo ratings yet

- Less Is MoreDocument3 pagesLess Is Moresnarf273No ratings yet

- Fine Grinding in The Australian Mining IndustryDocument11 pagesFine Grinding in The Australian Mining IndustryATon GarsaNo ratings yet

- Gearless Drives For Medium-Power Belt Conveyors: MotionDocument6 pagesGearless Drives For Medium-Power Belt Conveyors: MotionchalogdNo ratings yet

- Alimentador VibratorioDocument24 pagesAlimentador VibratoriojgarciacochachiNo ratings yet

- OBGETIVO: Un Sistema Integral de Protección Contra Rayos": Prof. Eduardo A. Cano PlataDocument28 pagesOBGETIVO: Un Sistema Integral de Protección Contra Rayos": Prof. Eduardo A. Cano PlataMauro AllaixNo ratings yet

- SBP7 Indar MotorsDocument16 pagesSBP7 Indar Motorsamk2009No ratings yet

- Brochure Leaching 4824 01 23 en MNGDocument8 pagesBrochure Leaching 4824 01 23 en MNGOsamaNo ratings yet

- Outotec Oktop Agitator Unit UpgradeDocument2 pagesOutotec Oktop Agitator Unit UpgradegicntNo ratings yet

- Bi0068130001 - Manual de PartesDocument677 pagesBi0068130001 - Manual de PartesMiguel angel Guerra Briceño100% (1)

- Volumen 1 Number 1Document32 pagesVolumen 1 Number 1dyka_737536No ratings yet

- Pebble Crusher Specific EnergyDocument10 pagesPebble Crusher Specific Energy12milehillNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภNo ratings yet

- AUMUND Apron FeedersDocument12 pagesAUMUND Apron Feederschannakeshava pandurangaNo ratings yet

- CRSH-OI-0004ENG TC-Series Cone Crushers Operation Instruction Manual - NOV2012Document72 pagesCRSH-OI-0004ENG TC-Series Cone Crushers Operation Instruction Manual - NOV2012Justice Machiwana100% (1)

- Peças CH430Document9 pagesPeças CH430Adriano MessiasNo ratings yet

- Series 800: Hydraulic Cable Winches - Standard FeaturesDocument6 pagesSeries 800: Hydraulic Cable Winches - Standard Featurespaolita_mahecha1265No ratings yet

- DE140 Spec Sheet 02 2018Document5 pagesDE140 Spec Sheet 02 2018Zeus ChillopaNo ratings yet

- Centrifugal Slurry Pumps: WarmanDocument2 pagesCentrifugal Slurry Pumps: WarmanDirceu ValadaresNo ratings yet

- NHI Brief IntroductionDocument56 pagesNHI Brief IntroductionThanhluan NguyenNo ratings yet

- SamplingDocument8 pagesSamplingSreedhar BellaryNo ratings yet

- Operation Philosophy ZLD-1 R-01Document11 pagesOperation Philosophy ZLD-1 R-01Ayon BoseNo ratings yet

- 502mva Transformer Installation ScheduleDocument4 pages502mva Transformer Installation ScheduleNaukhez A. KashifNo ratings yet

- Paper - Lufkin - Value of AutomationDocument9 pagesPaper - Lufkin - Value of AutomationMohamed GhareebNo ratings yet

- 1214-P Parber Industry Fine and UFC PCCDocument21 pages1214-P Parber Industry Fine and UFC PCCJuanDi Moreno CalderónNo ratings yet

- An Analysis of The Manufacturing Messaging SpecifiDocument15 pagesAn Analysis of The Manufacturing Messaging Specifihoangtien1991No ratings yet

- Star UMLDocument459 pagesStar UMLhoangtien1991No ratings yet

- DL8 User Manual PDFDocument158 pagesDL8 User Manual PDFhoangtien1991No ratings yet

- Product Ci853 ComliDocument3 pagesProduct Ci853 Comlihoangtien1991No ratings yet

- DL8 User Manual PDFDocument158 pagesDL8 User Manual PDFhoangtien1991No ratings yet

- Product Ci867 Modbus TCPDocument3 pagesProduct Ci867 Modbus TCPhoangtien1991No ratings yet

- Fault and Outage Management External WebinarDocument37 pagesFault and Outage Management External Webinarhoangtien1991No ratings yet

- InfoPLC Net FB CTRL FPBA 01 AC500 GuideDocument160 pagesInfoPLC Net FB CTRL FPBA 01 AC500 Guidehoangtien1991No ratings yet

- SD Memory Card Basic Module: Scalable PLC AC500Document46 pagesSD Memory Card Basic Module: Scalable PLC AC500hoangtien1991No ratings yet

- 3BDS011224 Eng Function DesignerDocument618 pages3BDS011224 Eng Function Designerhoangtien1991No ratings yet

- OEE-Industrial LED Displays PDFDocument3 pagesOEE-Industrial LED Displays PDFPartho SenguptaNo ratings yet

- PRO1 02E Training UnitsDocument10 pagesPRO1 02E Training UnitsMarinel MoraruNo ratings yet

- 12-CAD-CAM Modified by MR - Sanjay Kumar-11.9.2013 PDFDocument58 pages12-CAD-CAM Modified by MR - Sanjay Kumar-11.9.2013 PDFRajaReddyNo ratings yet

- High-Power-Rectifier-Systems-CATALOGO TECNICODocument16 pagesHigh-Power-Rectifier-Systems-CATALOGO TECNICOEdgardo Kat ReyesNo ratings yet

- Sewer System Design Standards: Adopted by The Santa Rosa City Council Resolution No. 25372 September 10, 2002Document32 pagesSewer System Design Standards: Adopted by The Santa Rosa City Council Resolution No. 25372 September 10, 2002Mohamed ElfawalNo ratings yet

- Project Life-Cycle MGT - JedDocument25 pagesProject Life-Cycle MGT - JedAndrew Ogwang OumaNo ratings yet

- Geh-6421 Vol I Mkvi Vol2Document350 pagesGeh-6421 Vol I Mkvi Vol2Bouazza100% (4)

- PLC ProgramiranjeDocument7 pagesPLC ProgramiranjeИван ЈовановићNo ratings yet

- Altivar 312: Variable Speed Drives For Asynchronous Motors PROFIBUS DP Communication ManualDocument37 pagesAltivar 312: Variable Speed Drives For Asynchronous Motors PROFIBUS DP Communication ManualMarcos AldrovandiNo ratings yet

- Automation Product Guide PDFDocument24 pagesAutomation Product Guide PDFLOTFI MEZGHANINo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- Premium and Atrium Using Unity Pro: Fipway Network User ManualDocument126 pagesPremium and Atrium Using Unity Pro: Fipway Network User ManualarfeemNo ratings yet

- Sequence Control RelayDocument10 pagesSequence Control RelayaggarwalakankshaNo ratings yet

- What Is AutomationDocument2 pagesWhat Is AutomationFaiz Syed MohammedNo ratings yet

- Engineering Change NoticeDocument30 pagesEngineering Change NoticeImam MansyurNo ratings yet

- Ansaldo SFC With High Generator Voltage - Automation & Control Engineering ForumDocument1 pageAnsaldo SFC With High Generator Voltage - Automation & Control Engineering ForumHBNBILNo ratings yet

- PLC Selection CriteriaDocument4 pagesPLC Selection Criteriasushant_jhawerNo ratings yet

- Take Up Brochure - Web PDFDocument16 pagesTake Up Brochure - Web PDFM Sulaiman0% (1)

- AJ5619 - Installation & Pre-Commissioning ReportDocument45 pagesAJ5619 - Installation & Pre-Commissioning ReportDeepakkumarNo ratings yet

- Home Downloads Live PLC Questions and Answers PLC Ebooks Contact Us Privacy Policy Advertise HereDocument2 pagesHome Downloads Live PLC Questions and Answers PLC Ebooks Contact Us Privacy Policy Advertise Hereskaderbe1100% (1)

- Rhapsody Fault Finding IZ132-5Document11 pagesRhapsody Fault Finding IZ132-5Jibjab7No ratings yet

- DELTA IA-HMI Allen Bradley Ethernet IP MicroLogix SLC500 CM en 20130823Document5 pagesDELTA IA-HMI Allen Bradley Ethernet IP MicroLogix SLC500 CM en 20130823MIke3479No ratings yet

- WT Micro Temperature Controller CatalogueDocument7 pagesWT Micro Temperature Controller CataloguepngchanhNo ratings yet

- Automation Lab ManualDocument56 pagesAutomation Lab ManualAthul BornNo ratings yet

- FX CommunicationDocument818 pagesFX CommunicationdinhvanbkNo ratings yet

- Anual: Movidrive MDX61B Extended Positioning Via Bus ApplicationDocument78 pagesAnual: Movidrive MDX61B Extended Positioning Via Bus Applicationleomar_bNo ratings yet

- TX-I/O™: Building TechnologiesDocument10 pagesTX-I/O™: Building Technologiessheraaz87No ratings yet

- Application of Scada For Water Treatment Plant: - by Shraddha Malve MT19ENV017Document34 pagesApplication of Scada For Water Treatment Plant: - by Shraddha Malve MT19ENV017Shraddha Malve100% (1)

- Lab ReportDocument84 pagesLab ReportusmanzahidNo ratings yet