Professional Documents

Culture Documents

1.0 Fundamentals of Casting

Uploaded by

Loo Tong ShianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.0 Fundamentals of Casting

Uploaded by

Loo Tong ShianCopyright:

Available Formats

1.

Fundamentals of Metal Casting

MANUFACTURIN

G PROCESSES

BFF 2423

CASTING

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Chapter Outline

1.

2.

3.

4.

5.

6.

Introduction

Solidification of Metals

Fluid Flow

Fluidity of Molten Metal

Heat Transfer

Defects

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

What is Metal Casting ?

It is defined as the process of producing a

metallic component by pouring and

allowing the liquid (metal or alloy) to

solidify in side a mold cavity of predesigned shape.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Terminology !!

Do not confuse

Casting (Verb): Process

Casting (noun) : Component

Casting process

2005 Pearson Education South Asia Pte Ltd

made by

1.0

Fundamentals of Metal Casting

Introduction

Casting is one of the most versatile

manufacturing processes

An ancient art with primitive skills

First metals cast were probably gold and

copper.

Cu melts at 1084 C

Gold melts at 1064 C

Egyptians were expert at investing or

lost wax casting

Allowed small intricate shapes to be cast.

Bronze casting

Made when people realized that copper tin alloys cast

much easier than copper alone.

Bronze casting of bells became important

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

What is casting??

One of the oldest processes

a) Melt metal/ alloy

b) pouring molten metal

into a mold cavity

c) Solidification (by

cooling the melt in the

mold)

d) remove the cast

component (also called

as casting) from the

mold

e) Finishing

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Advantages of Casting

Low cost and quick

Easier to manufacture

Can produce parts in one piece

Best suited for composite components

Can produce intricate shapes and internal

openings

Important Considerations

Flow of molten metal

Solidification and cooling

Type of mold material

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Solidification of Metals

After molten metal is poured into a mold, a series of events takes place during the

solidification of the metal and its cooling to ambient temperature.

These events greatly influence the size, shape, uniformity, and chemical composition of

the grains formed throughout the casting, which in turn influence its overall properties.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Pure Metals

Temperature as a function of time

for the solidification

2005 Pearson Education South Asia Pte Ltd

Density as a function of time

1.0

Fundamentals of Metal Casting

Pure Metals

After the temperature of the molten metal

drops to its freezing point, its temperature

remains constant while the latent heat of

fusion is given off.

At the mold walls, which are at ambient

temperature or at least are much cooler than

the molten metal, the metal cools rapidly and

produces a solidified skin or shell of fine

equiaxed grains.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Pure Metals

Pure metals

2005 Pearson Education South Asia Pte Ltd

Solidsolution

alloys

Nucleating

agents

1.0

Fundamentals of Metal Casting

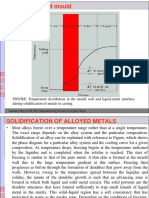

Alloys

Solidification in alloys begins when the

temperature drops below the liquidus, TL , and

is complete when it reaches the solidus, TS

Fig 10.4 shows the Schematic illustration of

alloy solidification and temperature distribution

in the solidifying metal.

Note the formation of dendrites in the mushy

zone.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Alloys

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Alloys

Within this temperature range, the alloy is

in a mushy or pasty state consisting of

columnar dendrites.

The width of the mushy zone (where both

liquid and solid phases are present) is an

important factor during solidification.

This zone is described in terms of a

temperature difference, known as the

freezing range, as follows:

Freezing range TL TS

2005 Pearson Education South Asia Pte Ltd

(10.1)

1.0

Fundamentals of Metal Casting

Alloys

For alloys, a short freezing range generally

involves a temperature difference of less than

50C, and a long freezing range greater than

110C.

Note that after 11 minutes of cooling, dendrites

reach each other, but the casting is still mushy

throughout. It takes about two hours for this

casting to solidify completely.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Alloys

Gray cast iron

Carbon steels

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Alloys

Effects of Cooling Rates

Slow cooling rates course grain structures,

large spacing between dendrite arms.

Faster cooling rates finer grain structures.

Grain size influence the properties of the

casting.

As grain size decreases, the strength and the

ductility of the cast alloy increase, prevent hot

tearing and/or cracks.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluid Flow

Fig 10.8 shows the schematic illustration of

a typical riser-gate casting.

Risers serve as reservoirs, supplying molten

metal to the casting as it shrinks during

solidification.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluid Flow

Basic casting system:

Fluid is pored though a pouring basin

Flows though the gating system into the mold cavit

1. Sprue is a vertical channel

though which the molten metal

flows downward in the mold

2. Runners channels that carry the

molten metal from the sprue to the

mold cavity

3. Gate is the portion of the runner

which the molten metal enters the

mold cavity

4. Risers serve as reservoirs to

supply the molten metal

necessary to prevent shrinkage.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluid Flow

Two basic principles of fluid flow:

Bernoullis theorem

This theorem is based on the principle of the

conservation of energy and relates pressure,

velocity, the elevation of the fluid at any

location in the system, and the frictional

losses in a system that is full of liquid.

Mass Continuity

The law of mass continuity states that for

incompressible liquids and in a system with

impermeable walls the rate of flow is constant.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluid Flow

Flow Characteristics

Turbulence is an important consideration in gating

systems.

Reynolds Number is used to quantify this aspect

0 < Re < 2000 laminar flow

2000<Re<20,000 mixture of laminar & turbulent flow

Re > 20 000 => severe turbulence

Techniques for minimizing turbulence

Avoid sudden changes in flow direction

Dross or slag can be eliminated by vacuum casting

Use of filters eliminates turbulent flow in the runner

system

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluidity of a Molten Metal

The capability of the molten metal to fill

mold cavities is called fluidity, which

consists of two basic factors: (1)

characteristics of the molten metal and (2)

casting parameters.

Molten Metal

1. Viscosity

As viscosity and its sensitivity to

temperature (viscosity index) increase,

fluidity decreases.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluidity of a Molten Metal

2. Surface Tension

A high surface tension of the liquid metal

reduces fluidity.

Because of this, oxide films on the surface

of the molten metal have a significant

adverse effect on fluidity.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluidity of a Molten Metal

3. Inclusions

Because they are insoluble, inclusions can

have a significant adverse effect on fluidity.

This effect can be verified by observing the

viscosity of a liquid (such as oil) with and

without sand particles in it; the liquid with

sand in it has a higher viscosity and, hence,

lower fluidity.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluidity of a Molten Metal

4. Solidifications pattern of alloy

The manner in which solidification takes

place can influence fluidity.

Moreover, fluidity is inversely proportional

to the freezing range.

The shorter the range (as in pure metals

and eutectics), the higher the fluidity.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluidity of a Molten Metal

Casting parameters

1. Mold Design

The design and dimensions of the spruce,

runners, and risers all influence fluidity.

2. Mold material and its surface

characteristics

Higher the thermal conductivity of the mold

and the rougher its surfaces, the lower the

fluidity of the molten metal.

Heating mold improves fluidity, but slows

down solidification process. Thus, develops

coarse grains and lower strength.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluidity of a Molten Metal

3. Degree of superheat

Superheat (defined as the increment of

temperature of an alloy above its melting point)

improves fluidity by delaying solidification.

The pouring temperature often is specified

instead of the degree of superheat, because it

is specified more easily.

4. Rate of pouring

The slower the rate of pouring molten metal

into the mold, the lower the fluidity because of

the higher rate of cooling when poured slowly.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Fluidity of a Molten Metal

5. Heat Transfer

This factor directly affects the viscosity of

the liquid metal.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Test for fluidity

The fluidity index is the length of the

solidified metal in the spiral passage. The

greater the length of the solidified metal,

the greater is its fluidity.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Heat Transfer

The heat transfer during the complete cycle

(from pouring, to solidification, and to

cooling to room temperature) is another

important consideration in metal casting.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Solidification time

During the early stages of solidification, a

thin, solidified skin begins to form at the

cool mold walls, and as time passes, the

thickness of the skin increases.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Solidification time

The solidification time is a function of the

volume of a casting and its surface area

(Chvorinovs rule):

Solidification time C

Volume

Surface area

10.7

where C is a constant that reflects (a) the

mold material, (b) the metal properties

(including latent heat), and (c) the

temperature.

The parameter n has a value between 1.5

and 2 but usually is taken as 2.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Shrinkage

Shrinkage, which causes dimensional

changes and (sometimes) cracking, is the

result of the following three sequential

events:

1. Contraction of the molten metal as it

cools prior to its solidification.

2. Contraction of the metal during phase

change from liquid to solid (latent heat of

fusion).

3. Contraction of the solidified metal (the

casting) as its temperature drops to

ambient temperature.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Shrinkage

The largest potential amount of

shrinkage occurs during the cooling of

the casting to ambient temperature.

The amount of contraction during the

solidification of various metals is shown

in Table 10.1.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Defects

hot tears in castings:

These defects occur because the casting

cannot shrink freely during cooling, owing

to constraints in various portions of the

molds and cores.

Exothermic (heat-producing) compounds

may be used (as exothermic padding) to

control cooling at critical sections to avoid

hot tearing.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Defects

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Common Defects in Casting

These defects can be minimized or eliminated by proper design and

preparation of molds and control of pouring procedures.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Defects

The International Committee of Foundry

Technical Associations has developed a

standardized nomenclature, consisting of

seven basic categories of casting defects

identified with boldface capital letters:

AMetallic projections

BCavities

CDiscontinuities

DDefective surface

EIncomplete casting

FIncorrect dimensions or shape

GInclusions

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Porosity

Porosity in a casting may be caused by

shrinkage, or gases, or both.

Porous regions can develop in castings

because of shrinkage of the solidified

metal.

Microporosity also can develop when the

liquid metal solidifies and shrinks

between dendrites and between dendrite

branches.

Gross porosity is from shrinkage and

usually is called a shrinkage cavity.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Porosity

Porosity caused by shrinkage can be reduced

or eliminated by various means such as:

i. Adequate liquid metal should be provided to

avoid cavities caused by shrinkage.

ii. Internal or external chills, as those used in

sand casting also are an effective means of

reducing shrinkage porosity.

iii. With alloys, porosity can be reduced or

eliminated by making the temperature

gradient steep.

iv. Subjecting the casting to hot isostatic pressing

is another method of reducing porosity.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Porosity

Fig 10.14 shows the various types of (a)

internal and (b) external chills (dark areas

at corners) used to eliminate porosity

caused by shrinkage.

2005 Pearson Education South Asia Pte Ltd

1.0

Fundamentals of Metal Casting

Concept Summary

Casting is a solidification process in which

molten metal is poured into a mold and allowed

to cool.

Solidification of pure metals takes place at a

constant temperature, whereas solidification of

alloys occurs over a range of temperatures.

Composition and cooling rates of the molten

metal affect the size and shape of the grains

and the dendrites.

Melting practices have a direct effect on the

quality of castings, as do foundry operations.

2005 Pearson Education South Asia Pte Ltd

1.0 Fundamentals of Metal Casting

Class Activity

1. Explain the reasons why heat transfer and fluid flow are

important in metal casting?

2. We know that pouring metal at a high rate into a mold has

certain disadvantages. Are there any disadvantages to

pouring it very slowly?

3. Why Reynolds number is important in casting?

4. Explain the reason of hot tearing in casting?

5. State the different between the short and long freezing

ranges?

6. What is different between the solidification of pure metals

and metal alloys?

7. How to test for fluidity?

8. Why it is important to remove dross/slag during pouring?

How?

9. What are some of the limitations of casting?

10. What does heat of fusion mean in casting?

2005 Pearson Education South Asia Pte Ltd

You might also like

- Effect of Shape and Size on SolidificationDocument6 pagesEffect of Shape and Size on Solidificationoğuz kağanNo ratings yet

- Materials: Electrochemical Polishing of Austenitic Stainless SteelsDocument25 pagesMaterials: Electrochemical Polishing of Austenitic Stainless SteelsSebin AbrahamNo ratings yet

- Forged Components Catalog For Pressure Vessel ConnectionsDocument72 pagesForged Components Catalog For Pressure Vessel ConnectionsForged ComponentsNo ratings yet

- Types of Sensors: ThermistorsDocument16 pagesTypes of Sensors: ThermistorsJinesh VinayachandranNo ratings yet

- Casting Fundamentals and DesignDocument35 pagesCasting Fundamentals and DesignRia Sharma0% (1)

- Heat Treatment of SteelsDocument60 pagesHeat Treatment of SteelsGUNJAN MUDGALNo ratings yet

- ASME B31.3 InterpretationsDocument44 pagesASME B31.3 InterpretationsChickenChick07No ratings yet

- VAAS Chlorine Service Ball Valves Design FeaturesDocument14 pagesVAAS Chlorine Service Ball Valves Design FeaturesReddy SadhanaNo ratings yet

- Shielded Metal Arc Welding: by Lakhveer SinghDocument77 pagesShielded Metal Arc Welding: by Lakhveer Singhਲਖਵੀਰ ਸਿੰਘ ਖਾਨਾNo ratings yet

- Buckling Stability Assessment of Plates PDFDocument9 pagesBuckling Stability Assessment of Plates PDFAryan BhattaraiNo ratings yet

- Casting (Metalworking) : Navigation SearchDocument26 pagesCasting (Metalworking) : Navigation SearchDion Satya GuntaraNo ratings yet

- Casting 1Document64 pagesCasting 1henokzewduNo ratings yet

- CHAPTER 1 - PneumaticDocument4 pagesCHAPTER 1 - Pneumaticaizuddin_zaihanNo ratings yet

- Composite Structures: Dinesh Kumar, S.B. SinghDocument13 pagesComposite Structures: Dinesh Kumar, S.B. Singhamit22141982No ratings yet

- Chapter 4 FurnacesDocument36 pagesChapter 4 FurnacesMohamed AlkharashyNo ratings yet

- Permanent Mold Casting Module - 2BDocument107 pagesPermanent Mold Casting Module - 2BZeeshan RafiqNo ratings yet

- ASME Section VIII Div 1 Pressure Vessel Design GuideDocument103 pagesASME Section VIII Div 1 Pressure Vessel Design GuideJaeup YouNo ratings yet

- Heat Exchnager, AUCDocument82 pagesHeat Exchnager, AUCSaid Alauddeen Faisz100% (1)

- Process Equipment DesignDocument27 pagesProcess Equipment DesignVivek NairNo ratings yet

- Hair Pin Heat Exchanger - BaherDocument11 pagesHair Pin Heat Exchanger - BahersbmmlaNo ratings yet

- Selection of Bolting Materials, Carbon and Alloy Steel For PDocument7 pagesSelection of Bolting Materials, Carbon and Alloy Steel For PswatkoolNo ratings yet

- Fatigue Failure Analysis and Fatigue Crack Growth ModelsDocument82 pagesFatigue Failure Analysis and Fatigue Crack Growth ModelspratyaygeminiNo ratings yet

- Bhel FinalDocument75 pagesBhel FinalKashyap KnNo ratings yet

- Manufacturing Process - Module2.0Document33 pagesManufacturing Process - Module2.0Fiza KamaNo ratings yet

- Dhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFDocument8 pagesDhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFRenan Gustavo PazNo ratings yet

- LMO14 LMO24 LMO44 Oil Burner Controls N7130enDocument16 pagesLMO14 LMO24 LMO44 Oil Burner Controls N7130enAhmed ShahenNo ratings yet

- OP1111Document5 pagesOP1111Umit AytarNo ratings yet

- Heating Element ArticleDocument10 pagesHeating Element ArticleFrea Kent-Dazze D'DrughiNo ratings yet

- Cooling for Sand Mould SolidificationDocument100 pagesCooling for Sand Mould Solidificationqwerty0987666No ratings yet

- Modified 2 1-4CrDocument45 pagesModified 2 1-4CrandreahankNo ratings yet

- Introduction to Pressure Vessel Design and AnalysisDocument122 pagesIntroduction to Pressure Vessel Design and AnalysisAnonymous d23gWCRQNo ratings yet

- ValveDocument9 pagesValveAdhie_ginthinkNo ratings yet

- Cold Box Overview enDocument18 pagesCold Box Overview enSasa DjordjevicNo ratings yet

- Norma Pipe Connections DIN-11864Document17 pagesNorma Pipe Connections DIN-11864bioNo ratings yet

- Welding - Processes, Metallurgy and Defects: Summer 2010Document25 pagesWelding - Processes, Metallurgy and Defects: Summer 2010daemsalNo ratings yet

- Clemex: ASTM E1268 Banding AnalysisDocument1 pageClemex: ASTM E1268 Banding Analysissmallik3No ratings yet

- Applied Strength of Materials For Engineering Technology - Purdue University Fort WayneDocument172 pagesApplied Strength of Materials For Engineering Technology - Purdue University Fort WayneJampel kun TsheringNo ratings yet

- Tool WearDocument8 pagesTool WearSai KrishnaNo ratings yet

- Sidhi Alcast: Product AuditDocument4 pagesSidhi Alcast: Product AuditRohit BiriwalNo ratings yet

- BS 4504 Slip On Flanges PDFDocument7 pagesBS 4504 Slip On Flanges PDFMaclean ArthurNo ratings yet

- Intergard 345 - DatasheetDocument4 pagesIntergard 345 - DatasheetmanuthomasNo ratings yet

- Heat Treatment: Prepared by Approved byDocument20 pagesHeat Treatment: Prepared by Approved byBhanu Pratap ChoudhuryNo ratings yet

- Elevated Temperature Fatigue of Pressure Vessel SteelsDocument6 pagesElevated Temperature Fatigue of Pressure Vessel SteelsJohnNo ratings yet

- Equivalent EvaporationDocument21 pagesEquivalent Evaporationkabbilaash kumarNo ratings yet

- Vibration NotesDocument77 pagesVibration NotesVipul AgrawalNo ratings yet

- Gain a complete understanding of key issues affecting Process Piping System designDocument9 pagesGain a complete understanding of key issues affecting Process Piping System designRamesh BaluNo ratings yet

- PED-Design Preliminaries-Mechanical Aspects - MergedDocument87 pagesPED-Design Preliminaries-Mechanical Aspects - Mergedsudhanshu shekharNo ratings yet

- CD4mcu Data SheetDocument1 pageCD4mcu Data SheetAde Bagus SetiawanNo ratings yet

- Nureg 6007Document122 pagesNureg 6007Baher ElsheikhNo ratings yet

- V B01B0005B-15GB PDFDocument20 pagesV B01B0005B-15GB PDFनिपुण कुमारNo ratings yet

- Lecture1460085501 2Document526 pagesLecture1460085501 2Smruti Ranjan Pattanayak100% (1)

- Development by TriangulationDocument22 pagesDevelopment by Triangulationsarahussain12367% (3)

- Pressure Points: Ask The EngineerDocument5 pagesPressure Points: Ask The EngineerMario MolinaNo ratings yet

- Effects of Root Gap and Bevel AngelDocument74 pagesEffects of Root Gap and Bevel AngeldaimaheshNo ratings yet

- MetalCasting 2Document38 pagesMetalCasting 2P2109 Praphul HampapuramNo ratings yet

- Chapter 1 - Fundamentals of Metal CastingDocument43 pagesChapter 1 - Fundamentals of Metal CastingSeab PisethNo ratings yet

- Foundry Technology SlidesDocument123 pagesFoundry Technology SlidesSeth Aboagye JnrNo ratings yet

- Lec 3b - Fluidity and SolidificationDocument49 pagesLec 3b - Fluidity and Solidificationnimdie jacksonNo ratings yet

- Brezs PresentationDocument13 pagesBrezs PresentationLoo Tong ShianNo ratings yet

- Assignment1 CsDocument18 pagesAssignment1 CsLoo Tong ShianNo ratings yet

- 1417671993.9844tutorial 4Document5 pages1417671993.9844tutorial 4Loo Tong ShianNo ratings yet

- PWMDocument6 pagesPWMLoo Tong ShianNo ratings yet

- InterruptDocument8 pagesInterruptLoo Tong ShianNo ratings yet

- Chapter6fatiguefailureloading 140824082905 Phpapp02Document24 pagesChapter6fatiguefailureloading 140824082905 Phpapp02Loo Tong ShianNo ratings yet

- Three-Phase A.C. CircuitsDocument32 pagesThree-Phase A.C. CircuitsĐỗ ĐứcNo ratings yet

- 1.0 Fundamentals of Machining (B)Document42 pages1.0 Fundamentals of Machining (B)Loo Tong ShianNo ratings yet

- SHEMITAHDocument29 pagesSHEMITAHxyoraywanNo ratings yet

- Manufacturing Engineering Fundamentals of MachiningDocument55 pagesManufacturing Engineering Fundamentals of MachiningLoo Tong ShianNo ratings yet

- Metal Casting Processes Chapter ExplainedDocument88 pagesMetal Casting Processes Chapter ExplainedTham Wai Hung89% (9)

- Foreva - Historic BuildingsDocument4 pagesForeva - Historic BuildingsHuy Nguyen VanNo ratings yet

- Gypsum Board Manufacturing ProcessDocument2 pagesGypsum Board Manufacturing Processeph100% (4)

- Katalog PT Gunung Garuda Steel WF ProfileDocument4 pagesKatalog PT Gunung Garuda Steel WF ProfileibnugantengNo ratings yet

- NFPA13 - Pt1 - Handout Cambios Nfpa 13Document33 pagesNFPA13 - Pt1 - Handout Cambios Nfpa 13Eden FriasNo ratings yet

- Effect of Preheating and Stress Relief on ASTM A516 Gr. 70 SteelDocument3 pagesEffect of Preheating and Stress Relief on ASTM A516 Gr. 70 SteelLalit ModiNo ratings yet

- Brick Masonry Work GuideDocument42 pagesBrick Masonry Work GuideParthJainNo ratings yet

- GP 36-15 - Materials Selection For Surface Topsides EquipmentDocument35 pagesGP 36-15 - Materials Selection For Surface Topsides Equipmentjujuroyale100% (4)

- Materials Today: Proceedings: Gowram Iswarya, Beulah MDocument8 pagesMaterials Today: Proceedings: Gowram Iswarya, Beulah Mshivanand hippargaNo ratings yet

- Alloys - All You Want To KnowDocument6 pagesAlloys - All You Want To KnowThaddeus LewisNo ratings yet

- q24 - 115 Hydropave Permeable PavingDocument4 pagesq24 - 115 Hydropave Permeable PavingadingkoanapintasNo ratings yet

- Standard Metallurgical TestingDocument7 pagesStandard Metallurgical TestingmirelamanteamirelaNo ratings yet

- ASTM A234-2011aDocument8 pagesASTM A234-2011aSam WeberNo ratings yet

- Rebar Splicing HandbookDocument76 pagesRebar Splicing HandbookgufajejamiNo ratings yet

- Alsina Mecanoconcept Experience 2017 LowDocument24 pagesAlsina Mecanoconcept Experience 2017 LowMiguel AngelNo ratings yet

- Lean ToToolShedDocument18 pagesLean ToToolShedYolohtli Vazquez Castaneda100% (1)

- FP03Document718 pagesFP03John Tejada IIINo ratings yet

- CRJGR Nrya DD S1.SSG Arc Asd 07860Document1 pageCRJGR Nrya DD S1.SSG Arc Asd 07860ihsanrahimNo ratings yet

- Cement Fineness Test (ASTM C 184 - 94)Document4 pagesCement Fineness Test (ASTM C 184 - 94)Hazem Diab33% (3)

- CementDocument11 pagesCementAstrid cNo ratings yet

- 18 Silbond and SilaidDocument4 pages18 Silbond and SilaidNikita KadamNo ratings yet

- Slabform BrochureDocument16 pagesSlabform BrochureAlform VGSINo ratings yet

- Weberep 360 FFRDocument2 pagesWeberep 360 FFRBasemNo ratings yet

- Specification - Tunnel Shotcrete LiningDocument43 pagesSpecification - Tunnel Shotcrete LiningAlhad Panwalkar100% (1)

- b2 - Floor FinishesDocument3 pagesb2 - Floor Finishesmuhammad faizNo ratings yet

- 3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Document2 pages3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Yesith AlmanzaNo ratings yet

- Identifier Suppliers List-GavinDocument5 pagesIdentifier Suppliers List-GavingavinNo ratings yet

- 75 Civil Engineering Questions & AnswersDocument2 pages75 Civil Engineering Questions & AnswersTimothy James M. MadridNo ratings yet

- Davco K11 FlexDocument2 pagesDavco K11 Flexjet toledoNo ratings yet

- Joint Coating Application & Pipe Coating ProcedureDocument7 pagesJoint Coating Application & Pipe Coating Proceduregst ajahNo ratings yet

- Valvula en Linea Norgren x30Document6 pagesValvula en Linea Norgren x30Base SistemasNo ratings yet