Professional Documents

Culture Documents

Inventory Control - Multi Echelon

Uploaded by

Duc Huan TranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inventory Control - Multi Echelon

Uploaded by

Duc Huan TranCopyright:

Available Formats

LOGO

Inventory control for multi-echelon system

Course of Inventory Management

Truong Ba Huy

ISE - Inventory Management

Characteristic

Items with Independent demand

Items with dependent demand

Truong Ba Huy

ISE - Inventory Management

Example 1: A Series Syste

Customer demand

External supply

Item 1

Item 2

Item N

Truong Ba Huy

ISE - Inventory Management

Example 2: An Assembly Syste

External supply

1

Customer demand

4

2

Truong Ba Huy

ISE - Inventory Management

Example 3: A Disassembly Syste

1

External

supply

6

4

7

Customer demand

Truong Ba Huy

ISE - Inventory Management

Example 4: A Distribution Syste

3

1

External supply

Customer demand

Truong Ba Huy

ISE - Inventory Management

Other Example

Disassembly/assembly systems

Assembly/distribution systems

Distribution systems with transshipments

Distribution systems with multiple supply

sources

Truong Ba Huy

ISE - Inventory Management

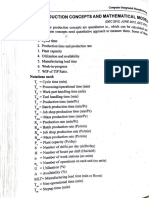

Lot Sizing with

Multiple Echelons

Truong Ba Huy

ISE - Inventory Management

Example

Product 1

Product 2

Intermediate G

Feed A

Reactor

Reactor

Reactor

Intermediate E

Feed B

Intermediate F

Intermediate H

Reactor

Reactor

Feed C

9

Feed D

Truong Ba Huy

10

ISE - Inventory Management

The Item-Task Network

Representation

End Product 1

End Product 2

Intermediate G

Feed A

Task

1

Task

2

Task

5

Task 2

Task 5

Intermediate E

Feed B

Intermediate F

Intermediate H

Task

4

Task

3

Feed C

10

Truong Ba Huy

11

ISE - Inventory Management

Items & Tasks

An item can be a component purchased from an

outside supplier or produced internally.

An item can be a raw material (e.g., a component),

a semi-finished (e.g., sub-assembly) or a finished

product.

A task can consume and produce multiple items

(components/intermediates/products).

An item can be consumed by more than one task;

similarly, an item can be produced by more than

one task.

Truong Ba Huy

12

ISE - Inventory Management

Example

Task

1

5

1

5

Task

2

Task

3

5

6

Task

4

Truong Ba Huy

13

ISE - Inventory Management

System Description

t: a period (e.g., day, week, month); t = 1, ,T,

where T represents the planning horizon

Drt: demand for item r in period t (number of units),

r=1,, R where R is the number of items

ir: number of units of item r needed to carry out task

i, i=1,, N where N is the number of tasks

ir: number of units of item r produced by task i

Truong Ba Huy

14

ISE - Inventory Management

Problem Statemen

Given a demand profile over a set of T periods

for each item (demand can be for either

finished or semi-finished products), determine

the quantity of each item to produce in each

period in order to minimize the production,

inventory and setup costs, while meeting

demand and without exceeding production

capacity.

Truong Ba Huy

15

ISE - Inventory Management

Formulations

Big bucket formulation (the production

planning problem)

Small bucket formulation (the production

scheduling problem)

Truong Ba Huy

16

ISE - Inventory Management

A Big-Bucket Formulatio

Tasks initiated in a period are completed during the

same period

The same task can be carried out multiple times during

a period

Items produced in a period can be used to satisfy

demand during that period

Demand in each period must be satisfied in that period;

no backorders allowed

There are no capacity limits (no limits on the number of

times a task can be carried out in a given period)

Truong Ba Huy

17

ISE - Inventory Management

Notation

Parameters

cit: variable cost of carrying out task i in period t,

i=1,, N where N is the number of tasks

Ait: fixed cost of carrying out task i in period t

(incurred at most once during each period)

hrt: cost of holding one unit of item r in inventory

from period t to period t+1

Truong Ba Huy

18

ISE - Inventory Management

Notation (Continued

Decision variables

Irt: inventory level of item r at the end of period t

Qit: the number of times task i is carried out in

period t

Yit = 1 if task i is initiated one or more times

during period i and Yit = 0 otherwise

Truong Ba Huy

19

ISE - Inventory Management

Notation (Continued

Amount of item r produced in period t =

Amount of item r consumed in period t =

N

i 1

N

i 1

irQit

irQit

Truong Ba Huy

20

ISE - Inventory Management

Formulation

Minimize

z t 1 i 1 cit Qit Ait Yit t 1 r 1 hrt I rt

T

subject to

I rt I r ,t 1 i 1 ir Qit i 1 ir Qit Drt , t , r

N

Qit MYit

i, t , r

Yit {0 ,1}

Qit , I rt 0

i, t

i, t , r

Truong Ba Huy

21

ISE - Inventory Management

Formulation

Minimize

c Q

T

t 1

i 1

it

it

Ait Yit t 1 r 1 hrt I rt

T

subject to

I rt I r ,t 1 i 1 ir Qit i 1 ir Qit Drt , t , r

N

Qit MYit

i, t , r

Yit {0 ,1}

Qit , I rt 0

M is a large number

i, t

i, t , r

Truong Ba Huy

22

ISE - Inventory Management

A Formulation with Capacity

Constraints and Multiple Machines

A machine may correspond to a single processor,

an assembly workstation, or a production line,

among others

It is possible for a task to be carried out on one or

more machines

A machine could possibly carry out more than one

task

A machine has a finite capacity and carrying out

any task consumes some of this capacity

Truong Ba Huy

23

ISE - Inventory Management

Notation

Utm: capacity of machine m in period t; m = 1, ,

M, where M is the number of machines

im: units of capacity of machine m needed to

carry out task i

ci,t,m: variable cost of carrying out task i on

machine m in period t

Ai,t,m: fixed cost of carrying out task i on machine m

in period t

Truong Ba Huy

24

ISE - Inventory Management

Note: A task that cannot be carried out on

a machine is assigned a very large

production cost.

Truong Ba Huy

25

ISE - Inventory Management

Notation (Continued

Qi,t,m: the number of times task i is carried out in

period t on machine m

Yi,t,m = 1 if task i is initiated one or more times

during period i on machine m and Yi,t,m = 0

otherwise

Truong Ba Huy

26

ISE - Inventory Management

Formulation

Minimize

c

T

t 1

i 1

m 1

i ,t , m

Qi ,t ,m Ai ,t ,mYi ,t ,m t 1 r 1 hrt I rt

T

subject to

I rt I r ,t 1 i 1 m 1 irQi ,t ,m i 1 m 1 irQi ,t ,m Drt , r , t

N

N

i 1

imQi ,t ,m U tm

t, m

U tmYi ,t ,m

im

i, t , m

Yi ,t ,m {0,1}

i, t , m

Qi ,t ,m

Qi ,t ,m , I rt 0

i , r , m, t

Truong Ba Huy

27

ISE - Inventory Management

A Formulation with Setup Time

A setup time si,m is incurred if task i is carried out

on machine m, one or more times in any given

period.

The capacity constraint is modified as follows

N

t, m

i 1imQi ,t ,m simYi ,t ,m U tm

Truong Ba Huy

28

ISE - Inventory Management

A Small-Bucket Formulatio

Time periods are chosen to be small enough so that

only one task on a particular machine can be either

initiated or completed

The processing time of each task consists of one or

more periods

A setup cost is incurred when the task initiated on a

machine is different from the task that was just

completed on that machine.

Truong Ba Huy

29

ISE - Inventory Management

Notation

i,m: processing time (in number of time periods) of

task i on machine m

Qi,t,m = 1 if task i is initiated on machine m at time t,

and Qi,t.m = 0 otherwise

Zi,t,m = 1 if machine m at time t is set up for task i

Truong Ba Huy

30

ISE - Inventory Management

Formulation

Minimize

m1 t 1 i 1 ci ,t ,mQi ,t ,m Ai ,t.mYi ,t ,m t 1 r 1 hrt I rt

M

subject to

I rt I r ,t 1 m 1 i 1 ir Qi .t i ,m ,m m 1 i 1 irQi ,t ,m Drt ,

M

Q

Z

i , m

u 1

i ,t u 1,m

i 1

i ,t , m

Z i ,t , m

Yi ,t ,m Z i ,t ,m Z i ,t 1,m

i , t , m

t , m

i , t , m

Qi ,t ,m & Z i ,t ,m {0,1}

I rt 0

0 Yi ,t ,m 1

i, t , m

r , t

i , t , m

r , t

Truong Ba Huy

31

ISE - Inventory Management

Solution Methods

Small to medium problems can be solved exactly

(to optimality)

Large problems may not solve within a reasonable

amount of time (the problem belongs to a class of

combinatorial optimization problems called NPhard)

Large problems can be solved approximately

using a heuristic approach

Truong Ba Huy

32

ISE - Inventory Management

Example Heuristic

Decompose the problem into a series of subproblems with smaller planning horizons

Decompose the problem into a series of

subproblems, each pertaining to a single item

Decompose the problem into one big bucket

problem (the production planning problem)

Solve the problem by relaxing one or more sets of

constraints

Solve the problem on a rolling horizon basis

You might also like

- Wreck It Ralph ScreenplayDocument114 pagesWreck It Ralph ScreenplayRebekah Sommerville100% (4)

- Computation of Area of A Closed TraversedDocument3 pagesComputation of Area of A Closed TraversedDaryl Ballesteros100% (1)

- Critical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.From EverandCritical Chain Project Management: A Concept Used By The Great Military and Aerospace Companies of The World.No ratings yet

- LADBS - Swimming PoolsDocument43 pagesLADBS - Swimming PoolsMichael James100% (1)

- Operations Cheat SheetDocument2 pagesOperations Cheat SheetmathiNo ratings yet

- Line BalancingDocument62 pagesLine BalancingDrBollapu Sudarshan100% (1)

- Learning CurveDocument62 pagesLearning CurveAnonymous Lwpgb4myYNo ratings yet

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- 526Document13 pages526jeas grejoy andrewsNo ratings yet

- (2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFDocument117 pages(2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFtariq.toffa4760No ratings yet

- Cat Marine Engine ProgramDocument4 pagesCat Marine Engine ProgramRobert BeddingfieldNo ratings yet

- Lecture - Little's LawDocument36 pagesLecture - Little's LawSamuel Bruce Rockson100% (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Space RequirementsDocument45 pagesSpace RequirementsRaj DeepanNo ratings yet

- A Survey of Lot Sizing and Scheduling ModelsDocument10 pagesA Survey of Lot Sizing and Scheduling ModelsClebson CardosoNo ratings yet

- Module 01 NumericalsDocument12 pagesModule 01 NumericalsRahulNo ratings yet

- BPR Managing Process FlowsDocument30 pagesBPR Managing Process FlowsPrudhvinadh KopparapuNo ratings yet

- Production and Operations Management SummeryDocument10 pagesProduction and Operations Management SummeryNermine LimemeNo ratings yet

- Production Planning MSPDocument8 pagesProduction Planning MSPbatman92No ratings yet

- Dynamic Version of The Economic Lot Size ModelDocument9 pagesDynamic Version of The Economic Lot Size ModelMuhammed LeeNo ratings yet

- Lot Sizing of Spare PartsDocument5 pagesLot Sizing of Spare PartsmladbosNo ratings yet

- Lecture Slide On Batch ProcessDocument49 pagesLecture Slide On Batch ProcessM RahmanNo ratings yet

- Aggregate Planning OptimizationDocument9 pagesAggregate Planning OptimizationSakura AlexaNo ratings yet

- DSIOPMA Learning CurveDocument3 pagesDSIOPMA Learning CurveGustav SanchezNo ratings yet

- Demand Forecasting and Material Requirement Planning Optimization Using Open Source ToolsDocument14 pagesDemand Forecasting and Material Requirement Planning Optimization Using Open Source ToolsSunav VidhyarthiNo ratings yet

- Chapter 3 - Batch ProcessesDocument59 pagesChapter 3 - Batch ProcessesAslamNo ratings yet

- MRP As An LP NotesDocument4 pagesMRP As An LP NoteshmurciaNo ratings yet

- How Work Sampling Determines Time StandardsDocument25 pagesHow Work Sampling Determines Time StandardsassaNo ratings yet

- PHM: Mining Periodic High-Utility ItemsetsDocument15 pagesPHM: Mining Periodic High-Utility ItemsetsSnehaArigaNo ratings yet

- EFIMDocument17 pagesEFIMLoges WaranNo ratings yet

- Thesis of Inventory Control With InflationDocument20 pagesThesis of Inventory Control With Inflationgarvitasingh100% (1)

- PPT8 - 11_Work Design_PMTS_Work Sampling_Worker-Machine RelationshipDocument33 pagesPPT8 - 11_Work Design_PMTS_Work Sampling_Worker-Machine RelationshipHASEL CONENo ratings yet

- Electronics Manufacturing Company Hand Assembly Productivity ImprovementDocument4 pagesElectronics Manufacturing Company Hand Assembly Productivity ImprovementPremchand RegarNo ratings yet

- Chapter III Econ 2021Document80 pagesChapter III Econ 2021biruk habtamuNo ratings yet

- 2 Herkansing PM 18 Mei 2016 Met Uitwerking Aangepast Voor CanvasDocument8 pages2 Herkansing PM 18 Mei 2016 Met Uitwerking Aangepast Voor CanvasKarim SalehNo ratings yet

- Quantitative Methods Techniques for Business PlanningDocument7 pagesQuantitative Methods Techniques for Business PlanningVivienne Lei BolosNo ratings yet

- Modeling and Solving The Periodic Maintenance ProblemDocument26 pagesModeling and Solving The Periodic Maintenance ProblemAndre Cuadros QuispeNo ratings yet

- Quezada2020 Report - Group 1Document19 pagesQuezada2020 Report - Group 1Hiền Trang Lê ThiênNo ratings yet

- Short Keys and Formulas of ExcelDocument40 pagesShort Keys and Formulas of ExcelSattar CANo ratings yet

- ENGINEERING DOCUMENT MANAGEMENTDocument16 pagesENGINEERING DOCUMENT MANAGEMENTMohamed AbdNo ratings yet

- Module 1 Capacity Planning and Line BalancingDocument2 pagesModule 1 Capacity Planning and Line BalancingJohnathan LavaredsNo ratings yet

- Fulfill Order 2Document14 pagesFulfill Order 2Aisyah Nisrina HamidahNo ratings yet

- Line Balance 059Document39 pagesLine Balance 059Sonam SinghNo ratings yet

- Demand forecasting and MRP optimization using open source toolsDocument15 pagesDemand forecasting and MRP optimization using open source toolsJorge RomeroNo ratings yet

- Process AnalysisDocument26 pagesProcess AnalysisSankha BhattacharyaNo ratings yet

- Predetermined motion time systems explainedDocument43 pagesPredetermined motion time systems explainedArun R UNo ratings yet

- SequencingDocument95 pagesSequencingumangwarNo ratings yet

- Industrial AssignmentDocument7 pagesIndustrial AssignmentParyant RastogiNo ratings yet

- Eecurve OokDocument16 pagesEecurve Ookমুহম্মদইরশাদNo ratings yet

- 3rd 4th Class FullDocument10 pages3rd 4th Class FullLag droidNo ratings yet

- 2016 FHM+ Utility Mining LengthDocument12 pages2016 FHM+ Utility Mining Lengthayissiraoul485No ratings yet

- Unit 5 - Learning Curve AnalysisDocument6 pagesUnit 5 - Learning Curve AnalysisAlyana GeriNo ratings yet

- Final Exam Activity Production PlanningDocument6 pagesFinal Exam Activity Production Planningjenyfer muñosNo ratings yet

- Lecture-5 Single Machine Scheduling 29aug22Document27 pagesLecture-5 Single Machine Scheduling 29aug22motted groupNo ratings yet

- CHP 3 ProductionDocument7 pagesCHP 3 ProductionJoel FdezNo ratings yet

- EOQ model and work measurement techniquesDocument3 pagesEOQ model and work measurement techniquesshaik safiyaNo ratings yet

- EHU-601 Industrial ManagementDocument214 pagesEHU-601 Industrial Managementvivek.birla100% (1)

- Industrial Engineering Maintenance Capacity Planning Level StrategyDocument16 pagesIndustrial Engineering Maintenance Capacity Planning Level Strategyb_shadid8399No ratings yet

- OM Inventory Systems & Simulation GameDocument39 pagesOM Inventory Systems & Simulation GamesilentrockerNo ratings yet

- Development of A SystemDocument7 pagesDevelopment of A SystemIgor LutsenkoNo ratings yet

- Operation Exam NotesDocument16 pagesOperation Exam NotesZaki KamardinNo ratings yet

- GANTT CHART PLANNING AND LEARNING CURVE ANALYSISDocument3 pagesGANTT CHART PLANNING AND LEARNING CURVE ANALYSISChristine NionesNo ratings yet

- Jobshop and MLDocument12 pagesJobshop and MLMahmoud ZhiouaNo ratings yet

- PmtsDocument46 pagesPmtsDhiraj ZanzadNo ratings yet

- 2 Work Study (Part 4) - GKDocument27 pages2 Work Study (Part 4) - GKGavierez, Fionnah Ysabelle A.No ratings yet

- Solution Report - ProjectOR11Document1 pageSolution Report - ProjectOR11Duc Huan TranNo ratings yet

- SingingDocument1 pageSingingDuc Huan TranNo ratings yet

- HelloDocument1 pageHelloDuc Huan TranNo ratings yet

- Special Study ReportDocument16 pagesSpecial Study ReportDuc Huan TranNo ratings yet

- The Enchanted ForestDocument3 pagesThe Enchanted ForestRichealle Vaniel Delicano SeverinoNo ratings yet

- Untitled Document-7Document13 pagesUntitled Document-7Ranjan singh BhadoriyaNo ratings yet

- International TradeDocument28 pagesInternational TradeAmit Sharma0% (1)

- 51-11-15-001-Data Recording of Allowable Damage and Repairs-A320Document6 pages51-11-15-001-Data Recording of Allowable Damage and Repairs-A320FredNo ratings yet

- Matrix Analysis of Networks: J. R. LucasDocument63 pagesMatrix Analysis of Networks: J. R. LucasNethmini SamarawickramaNo ratings yet

- 842e In001 - en PDocument4 pages842e In001 - en PNilson Eduardo TorresNo ratings yet

- 5.3 Resource - Allocation - of - Downlink - Heterogeneous - NOMA - Network - Based - On - Multi-User - With - Different - SpeedsDocument5 pages5.3 Resource - Allocation - of - Downlink - Heterogeneous - NOMA - Network - Based - On - Multi-User - With - Different - SpeedsmuradNo ratings yet

- The Journey of HIV 1 Non-Nucleoside Reverse TranscriptaseDocument33 pagesThe Journey of HIV 1 Non-Nucleoside Reverse TranscriptaseAnkit Kumar SinghNo ratings yet

- CS410 Series and CS417: User's GuideDocument209 pagesCS410 Series and CS417: User's Guident11No ratings yet

- Cash Valve Product OverviewDocument16 pagesCash Valve Product OverviewestebanNo ratings yet

- Presentation by Harshal Sethiya N Mitul UpadhyayDocument26 pagesPresentation by Harshal Sethiya N Mitul Upadhyaysanket jain100% (1)

- The Fundamental Building Block: The CellDocument12 pagesThe Fundamental Building Block: The CellTanish JenaNo ratings yet

- Begone!: Short Story With Vocabulary For Talking About Love (Level B1-B2)Document5 pagesBegone!: Short Story With Vocabulary For Talking About Love (Level B1-B2)Hitesh MishraNo ratings yet

- Ceng3181-Transport Engineering: Haramaya Institute of Technology Department of Civil EngineeringDocument31 pagesCeng3181-Transport Engineering: Haramaya Institute of Technology Department of Civil EngineeringMuaz HararNo ratings yet

- Tzu Chi Medical Journal: Xiao-Jun Lin, I-Mei Lin, Sheng-Yu FanDocument5 pagesTzu Chi Medical Journal: Xiao-Jun Lin, I-Mei Lin, Sheng-Yu Fanperisici4_535458722No ratings yet

- trs5 Key Cho Cac BanDocument35 pagestrs5 Key Cho Cac BanNguyệt NgôNo ratings yet

- Um Centuris Pro Li900b1 - enDocument70 pagesUm Centuris Pro Li900b1 - enOsires Ferreira100% (1)

- Single Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDocument30 pagesSingle Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDeepak GuptaNo ratings yet

- 10TH Gseb PaperDocument10 pages10TH Gseb Paperkhushboo guptaNo ratings yet

- 2019-Ag-8750 Poultry Farm Visit ReportDocument7 pages2019-Ag-8750 Poultry Farm Visit ReportYOUSAF0% (1)

- Incepbio Project PPT - 080124Document21 pagesIncepbio Project PPT - 080124adminpuneNo ratings yet

- RCCHEMDocument10 pagesRCCHEMKartik PandeyNo ratings yet

- Cinnamon Streusel Muffin Recipe (Coffee Cake) - DDocument3 pagesCinnamon Streusel Muffin Recipe (Coffee Cake) - DBryce MitchellNo ratings yet

- Artists Budget TemplateDocument9 pagesArtists Budget TemplateMaia CelloNo ratings yet