Professional Documents

Culture Documents

Developing A Concrete Mix Design Manual For Nigeria

Uploaded by

Emeso OjoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Developing A Concrete Mix Design Manual For Nigeria

Uploaded by

Emeso OjoCopyright:

Available Formats

DEVELOPING A CONCRETE

MIX DESIGN MANUAL FOR

NIGERIA ANALYSIS OF

TEST RESULTS

CONCRETE RESEARCH GROUP

Matawal Danladi S.

Ojo Emeso B.

Gai Friday I.

Adamu Isah K.

Tyoden Juliana N.

Chukwuma Gerald O.

CONCRETE

Concrete is one of the most widely

used construction materials

It is a composite building material

Widespread use of concrete

Effectiveness,

Cost and

Performance for most construction

works.

Its ability to exhibit such properties is

a function of the constituents as well

as

the

proportions

of

these

constituents.

Can be designed for strength ranging

from 10N/mm2 to 100N/mm2, making

it an extremely versatile building

material.

The basic constituents remain

Concrete Mix Design

The primary objective is to select suitable

constituent materials and determine their

required amounts in order to produce concrete

of specific characteristics and properties as

economically as possible.

Major Characteristics

Workability,

Strength and

Durability.

Other characteristics include density, thermal characteristics,

elastic modulus etc.

Performance of concrete is dependent on the required

performance of concrete in two states: the fresh/plastic and

hardened states.

Constituent Materials - Cement

Cement is the basic constituent material in

concrete.

Concrete is formed when cement creates a paste

with water that binds with sand and gravel to

harden.

Significant Properties and Quality Indicators

Strength Class

Water to Cement ratio

Constituent Materials Aggregates

Significant component of concrete which

constitutes 70-80% of total volume

Significant Properties

Size of Aggregates: Fine and Coarse

Particle Size Distribution

Specific gravity

Maximum size of aggregates

Nature of aggregates

Water absorption

Shape of aggregates.

Objective

To develop a manual which provides a step by

step procedure for carrying out mix designs

for the various grades of concrete by

deducing the appropriate quantities of

materials required for each mix.

Methodology

Adoption of BRE Method (British Standards) as a

baseline

Series of tests were carried out on major

constituents: aggregates and cement to ensure

conformity with British Standards

Mix Design was carried out using the British

Standards to ascertain required proportions for

various concrete mixes

Sixteen cubes were prepared for each mix

Workability was verified for each mix

Compressive Strength and Density was determined

at various ages of concrete

Comparison of charts developed with BS charts

Scope of Project

Maximum Aggregate Size: 10mm and 20mm

Strength class of cement: 32.5, 42.5 and

52.5

Slump: 30-60mm and 60-180mm

Compressive strength at different ages of

concrete: 3, 7, 14 and 28 days

Concrete grade: 20, 25, 30, 35, 40 and 50

Type of fine aggregate: stone dust and river

sand

Properties of Aggregate Used

Test

Aggregate

Value

Specification

Impact Value

13.72

45 (BS 882 )

Crushing

27.29

45 (BS 882 )

Value %

Flakiness %

Specific

21.25

40 (BS 882 )

2.67

2.3 2.9

0.3

0.2 4

2.45

2.3 2.9

0.26

0.2 - 2

%

Aggregate

Gravity

(Coarse

Aggregate)

Absorption %

(Coarse

Aggregate)

Specific

Gravity (Fine

Aggregate)

Absorption %

(Fine

10

Sieve Analysis of Coarse aggregates

Grading Envelope for maximum size 20mm

120.00

19.05mm

Upper Limit

100.00

Lower Limit

12.7mm

80.00

60.00

40.00

Grading Envelope for maximum size 10mm

120.00

20.00

9.53mm

Lower Limit

100.00

0.00

1

10

Upper Limit

100

12.7mm

80.00

60.00

40.00

20.00

0.00

1

10

100

11

Sieve Analysis of Coarse

aggregates

19mm + 12.5 mm for Maximum Size 20mm

100.00

80.00

60.00

Percentage Passing %

40.00

20.00

0.00

1

10

Sieve Size mm

100

12.5mm + 10.5mm for Maximum size 10mm

100.00

80.00

60.00

Percentage Passing %

40.00

20.00

0.00

1

10

Sieve Size mm

100

12

Combined Gradation of

Aggregates

Proportions %

Aggregate Size

mm

0 -- 4

4--8

8--16

16--20

Maximum size 10mm Maximum size 20mm

50.00

50.00

---

100.00

80.00

100.00

Grading

curve

80.00

Upper Limit

60.00

45.00

25.00

24.00

6.00

Lower Limit

60.00

Percentage Passing %

40.00

Grading curve

Percentage Passing %

40.00

Upper Limit

Lower Limit

20.00

0.00

0.1

20.00

1

Sieve Size mm

10

0.00

0.1

1

Sieve Size mm

10

13

Properties of Cement Used

32.5N

TEST PARAMETER

RESULT

Specific Gravity

3.1

Fineness %

34.2

Soundness (Expansion using le

chatelier mould) mm

0.75

Setting time:

Initial setting time

final setting time

(mins)

2 day Compressive Strength

N/mm2

7 day Compressive Strength

TEST PARAMETER

N/mm2

28 day Compressive Strength

Specific

Gravity

N/mm2

Fineness %

Soundness (Expansion using le

chatelier mould) mm

23

42.5R

RESULT

37.2

3.12

47.4

24.9

1

Satisfactory

30.6

Satisfactory

STANDARD

16

NIS 4441:2003

2.5

NIS 4441:2003

10mm

142

final setting time

2

Satisfactory

NIS 444-1:2003

60mins

600mins

187

(mins)

2 day Compressive Strength

REMARKS

127

(mins)

185

Setting time:

Initial setting time

(mins)

STANDARD

NIS 444-1:2003

2.5

NIS 4441:2003

10mm

NIS 4441:2003

60mins

600mins

REMARKS

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Compressive Strength against Age

Compressive Strength N/mm2

Satisfactory

Age (days)

32.5N

42.5R

14

Mix Design Procedure

Step 1: Determination of target mean strength

Step 2: Determination of Water-cement ratio

Step 3: Determination of water content

Step 4: Determination of cement content

Step 5: Determination of aggregate content

15

Mix Design Procedure

Step 1: Determination of target mean strength

fm = the target mean strength

fc = the specified characteristic strength

k = a constant (taken as 1.64 for a 5% defective level)

s = standard deviation

where

16

Mix Design Procedure

Step 2: Determination of Water-cement ratio

80

42.

5

70

60

50

40

Compressive Strength

30

20

10

0

0.3

0.4

0.5

0.6

0.7

Water cement ratio

0.8

0.9

Relationship between free water cement ratio and compressive

strength of concrete for different cement strength (Adopted from

BRE 2009)

17

Mix Design Procedure

Step 3: Determination of water content

Maximum size of

aggregate mm

10

20

40

Type of

aggregate

Uncrushed

Crushed

Uncrushed

Crushed

Uncrushed

Crushed

Water Content kg/m3

Slump 0- Slump

10

10-30

Slump

30-60

Slump

60-180

150

180

205

225

180

205

230

250

135

160

180

195

170

190

210

225

115

140

160

175

155

175

190

205

Approximate Free water contents required to give

various levels of workability (Adopted from BRE 2009)

18

Mix Design Procedure

Step 4: Determination of cement content

19

Mix Design Procedure

Step 5: Determination of aggregate content

2800

2700

2600

2500

Relative density

of combined

aggregate (on

saturated and

2.4 surface dry basis)

Linear (2.4)

Wet density of concrete mix kg/m3 2400

2.5

2300

2.6

2200

2100

2.7

2.8

2.9

Free water content kg/m3

where

Co = wet density of concrete (kg/m3)

C = cement content (kg/m3)

W = free water content (kg/m3)

20

21

Production of Concrete Cubes

22

Relationship between age of concrete and

compressive strength of concrete: 32.5N

35

40

G20

30

25

30

20

25

Compressive

Strength N/mm2

15

10

5

0

0

10

15

20

Age of Concrete (days)

G25

35

10mm/30-60

S lump

10mm/60-180

S lump

20mm/30-60

S lump

25

30

20

Compressive Strength N/mm2

15

10

5

0

0

60

50

G35

45

10

15

20

Age of Concrete (days)

25

30

G40

50

40

10mm/30-60

S lump

10mm/60-180

S lump

20mm/30-60

S lump

40

35

30

25

Compressive Strength N/mm2

20

15

30

Compressive Strength N/mm2

10mm/30-60

S lump

10mm/60-180

S lump

10

20mm/30-60

S lump

5

0

0

10

15

20

Age of Concrete (days)

25

30

20

10

0

0

10

15

20

Age of Concrete (days)

10mm/30-60

S lump

10mm/60-180

S lump

20mm/30-60

S lump

25

30

23

Relationship between age of concrete and

compressive strength of concrete: 32.5N

45

70

G30

40

35

30

50

25

40

Compressive

Strength N/mm2

20

Compressive

Strength N/mm2

30

15

10mm/30-60

S lump

10

10mm/60-180

S lump

20

20mm/30-60

S lump

10

5

0

5

10

15

20

Age of Concrete (days)

G50

60

25

30

10mm/30-60

S lump

10mm/60-180

S lump

20mm/30-60

S lump

0

5

10

15

20

Age of Concrete (days)

25

30

24

Relationship between age of concrete and

compressive strength of concrete: 42.5R

35

35

G20

30

G25

30

25

25

20

Compressive

Strength N/mm2

15

10

5

0

0

10

15

20

Age of Concrete (days)

45

20

10mm/30-60

S lump

10mm/60-180

S lump

20mm/30-60

S lump

25

30

10mm/60-180

S lump

20mm/30-60

S lump

5

0

5

40

30

35

25

30

15

10mm/30-60

S lump

10mm/60-180

S lump

20mm/30-60

S lump

10

5

0

0

10

15

20

Age of Concrete (days)

10

15

20

Age of Concrete (days)

45

35

Compressive

Strength N/mm2

20

25

30

10mm/30-60

S lump

10

G30

40

Compressive

Strength N/mm2

15

25

30

G35

25

Compressive

Strength N/mm2

20

10mm/30-60

S lump

15

10

10mm/60-180

S lump

5

0

0

10

15

20

Age of Concrete (days)

25

30

25

Relationship between age of concrete and

compressive strength of concrete: 42.5R

60

60

G40

50

G50

50

40

40

30

Compressive Strength N/mm2

20

10

0

0

10

15

20

Age of Concrete (days)

30

Compressive Strength N/mm2

10mm/30-60

S lump

10mm/60-180

S lump

20mm/60-180

S lump

25

30

20

10

0

0

10

15

20

Age of Concrete (days)

10mm/30-60

S lump

10mm/60-180

S lump

20mm/30-60

S lump

25

30

Increase of compressive strength with age of concrete

Characteristic strength of concrete was achieved by 7 days in most

cases

The higher the 3-day compressive strength, the higher the 28-day

compressive strength

About 70% of 28 day strength is achieved within the first three days;

about 80% is achieved by seven days and 90% is achieved by 14 days

26

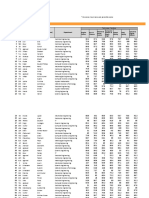

True Slump Attained

32.5

42.5

10mm

Max Size

of Aggt

20mm

10mm

20mm

Design

Slump

mm

30-60

60-180

30-60

60-180

30-60

60-180

30-60

60-180

20

30

179.5

51

77.5

50

149

25

85

25

40

179.5

49.5

82.5

45

172

53

137

30

43

175

35

60.5

43

155

46

91

35

27.5

90

49.5

28

53

108

45

71

40

10

18.5

50

50

56

122

46

49.5

50

12

nil

nil

40

63

nil

nil

27

Relationship between compressive strength

and water cement ratio: 32.5N

70

Characteristic Strength

Target Strength

60

30-60 Slump (10mm)

60-180 Slump (10mm)

50

30-60 Slump (20mm)

60-180 Slump (20mm)

40

Compressive Strength N/mm2

30

20

10

0

0.3

0.35

0.4

0.45

0.5

Water - Cement ratio

0.55

0.6

0.65

0.7

28

Relationship between compressive strength

and water cement ratio: 32.5N

70

60

50

f(x) = - 89.05x + 86.06

R = 0.81

40

Compressive Strength N/mm2

30

20

10

0

0.3

0.35

0.4

0.45

0.5

Water - Cement ratio

0.55

0.6

0.65

0.7

29

Relationship between compressive strength

and water cement ratio: 42.5R

Characteristic Strength

70

Target Strength

30-60 Slump (10mm)

60

60-180 Slump (10mm)

30-60 Slump (20mm)

50

60-180 Slump (20mm)

40

Compressive Strength N/mm2

30

20

10

0

0.3

0.35

0.4

0.45

0.5

Water Cement ratio

0.55

0.6

0.65

0.7

30

Relationship between compressive strength

and water cement ratio: 42.5R

60

50

f(x) = - 86.93x + 83.12

R = 0.88

40

30

20

10

0

0.3

0.35

0.4

0.45

0.5

0.55

0.6

0.65

0.7

31

Proposed Relationship between compressive

strength and water cement ratio

70

60

50

40

Compressive Strength N/mm2

30

British Method 42.5

20

Nigerian Method 32.5

Nigerian Method 42.5

10

0

0.3

0.35

0.4

0.45

0.5

Water-Cement ratio

0.55

0.6

0.65

0.7

32

Conclusion/ Recommendations

Further tests would need to be conducted to

verify/adjust proposed charts

Aggregates: Emphasize the need for combined

gradation of aggregates and discourage the use of

one size aggregates for construction in Nigeria

Controversy of recommendations of specific

applications of cement based on strength class by

SON may need to be revisited.

Development of Software/model to aid in the mix

design process

33

Thank you for

listening

You might also like

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980From EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980No ratings yet

- Translucent ConcreteDocument22 pagesTranslucent ConcreteRicha ShahNo ratings yet

- Cement: CIEN 30023 S.Y. 2ND SEM 2020-2021Document32 pagesCement: CIEN 30023 S.Y. 2ND SEM 2020-2021Mhervin BisisNo ratings yet

- Self Compacting ConcreteDocument16 pagesSelf Compacting ConcreteAnubhab GhoshNo ratings yet

- Construction Materials - Chemical AdmixturesDocument46 pagesConstruction Materials - Chemical AdmixturesWelday TsegayNo ratings yet

- Chloride ResistanceDocument37 pagesChloride ResistanceCarlos Augusto Sánchez Rondón100% (1)

- High Strength Concrete Using Chemical AdmixtureDocument21 pagesHigh Strength Concrete Using Chemical AdmixtureYati AggarwalNo ratings yet

- Silica FumeDocument24 pagesSilica FumeRatna Sai0% (1)

- Recent Progress in Concrete-Polymer CompositesDocument10 pagesRecent Progress in Concrete-Polymer Compositesswathi1105No ratings yet

- Construction Materials and TestingDocument61 pagesConstruction Materials and TestingAliñabo RoqueNo ratings yet

- Concrete TechnologyDocument61 pagesConcrete TechnologyShakeel Waseem100% (2)

- Self Compacting ConcreteDocument9 pagesSelf Compacting ConcreteSiva KrishnaNo ratings yet

- Setting Time of ConcreteDocument2 pagesSetting Time of ConcretevempadareddyNo ratings yet

- Introduction of Cement: When Was Cement Begin?Document11 pagesIntroduction of Cement: When Was Cement Begin?مايف سعدونNo ratings yet

- Supplementary Cementing MaterialsDocument59 pagesSupplementary Cementing MaterialsTruong Giang VoNo ratings yet

- Engineering Materials: CementDocument26 pagesEngineering Materials: CementSathvika KodimyalaNo ratings yet

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Document6 pagesExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- DES 6614 Clay BricksDocument33 pagesDES 6614 Clay BricksbiniNo ratings yet

- Self Compacting ConcreteDocument20 pagesSelf Compacting ConcreteNaveen ReddyNo ratings yet

- Slef Cleaning Concrete PDFDocument9 pagesSlef Cleaning Concrete PDFP Guru RajuNo ratings yet

- Dr. C. D. Modhera - Day 3 - Session 1Document93 pagesDr. C. D. Modhera - Day 3 - Session 1mbgfknjhgfNo ratings yet

- Concrete Flow TestDocument7 pagesConcrete Flow TestDarrenTofuNo ratings yet

- Comparative Study of Polymer Fibre Reinforced Concrete With Conventional Concrete PavementDocument5 pagesComparative Study of Polymer Fibre Reinforced Concrete With Conventional Concrete PavementesatjournalsNo ratings yet

- Cement & Concrete 2023Document42 pagesCement & Concrete 2023Joel MisaNo ratings yet

- GRAYBEAL (2006) - Material Property Characterization of UHPC (Mechanical and Durability)Document188 pagesGRAYBEAL (2006) - Material Property Characterization of UHPC (Mechanical and Durability)Carolina LiviNo ratings yet

- Facade Construction For Stone CladdingDocument8 pagesFacade Construction For Stone CladdingsanjayNo ratings yet

- Concrete: Various Terms Used / Steps For Concreting Operation A) BatchingDocument5 pagesConcrete: Various Terms Used / Steps For Concreting Operation A) BatchingDARK KnightNo ratings yet

- No Fines ConcreteDocument5 pagesNo Fines ConcretedannyNo ratings yet

- Reactive Powder Concrete Done By, C.Sugashini, B. Kanchana, RA. AkshayaDocument35 pagesReactive Powder Concrete Done By, C.Sugashini, B. Kanchana, RA. AkshayaAkshaya RohiniNo ratings yet

- Owners: White Cement Concrete and Colored Concrete ConstructionDocument4 pagesOwners: White Cement Concrete and Colored Concrete ConstructionsonofalexanderNo ratings yet

- Concrete: From Grey To GreenDocument12 pagesConcrete: From Grey To GreenOmar Marghani SalmaNo ratings yet

- Admixtures: Presented by Engr. Malik Hammad NaseerDocument32 pagesAdmixtures: Presented by Engr. Malik Hammad Naseerkhalid khanNo ratings yet

- RMC Civil EngineeringDocument27 pagesRMC Civil EngineeringPavan Kumar100% (1)

- SeminarDocument21 pagesSeminarsoukhya100% (1)

- Chapter 5 MortarDocument6 pagesChapter 5 MortarSabrina AlyaNo ratings yet

- Concret CementDocument29 pagesConcret CementKamal Hameed Al-taiy100% (1)

- Standards and Update For Concrete Block Paving and Paving Flags in The United KingdomDocument6 pagesStandards and Update For Concrete Block Paving and Paving Flags in The United KingdomΓιάννης ΜούσιαςNo ratings yet

- Dinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiDocument7 pagesDinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiRabish ANo ratings yet

- SCCDocument10 pagesSCCPrakash NanthagopalanNo ratings yet

- Project:: Use of Metakaoline and Alccofine As A Admixture in ConcreteDocument52 pagesProject:: Use of Metakaoline and Alccofine As A Admixture in ConcreteAnonymous wlbOBqQWDNo ratings yet

- Field Tests On BricksDocument3 pagesField Tests On Bricksdongrey331No ratings yet

- TVBM 3104Document257 pagesTVBM 3104Bianca CalderónNo ratings yet

- Setting and Hardening ConcreteDocument24 pagesSetting and Hardening Concreteabdulwahab1175% (4)

- Normal Concrete Mix DesignDocument4 pagesNormal Concrete Mix Designmurnal0% (1)

- W3 - L8 - MRCS - Concrete Deterioration - 3 PDFDocument42 pagesW3 - L8 - MRCS - Concrete Deterioration - 3 PDFsrinivasanNo ratings yet

- CLAYDocument41 pagesCLAYSwapna PandeNo ratings yet

- BASF Introduces Smart Dynamic ConcreteDocument4 pagesBASF Introduces Smart Dynamic ConcreteNurul Hidayati100% (1)

- Self Compacting Concrete & Pre Placed ConcreteDocument33 pagesSelf Compacting Concrete & Pre Placed Concretesanthu256100% (2)

- Cellular Light Weight ConcreteDocument35 pagesCellular Light Weight ConcreteUTP gamingNo ratings yet

- Carbon Footprint of Concrete Buildings Seen in The Life Cycle Perspective PDFDocument14 pagesCarbon Footprint of Concrete Buildings Seen in The Life Cycle Perspective PDFGoodson ChitsaNo ratings yet

- Chloride Ingress Seminar P 01 6Document357 pagesChloride Ingress Seminar P 01 6cap300050% (2)

- Carbonation Resistance of One Industrial Mortar Used As A Concrete CoatingDocument5 pagesCarbonation Resistance of One Industrial Mortar Used As A Concrete CoatingViníciusNo ratings yet

- Pervious Concrete - An Overview: Karthik H. OblaDocument10 pagesPervious Concrete - An Overview: Karthik H. OblaRuthra ManickamNo ratings yet

- Kathmandu University: Construction of Cement Concrete PavementsDocument37 pagesKathmandu University: Construction of Cement Concrete Pavementspasang ghising100% (1)

- Fundamentals of ConcreteDocument53 pagesFundamentals of ConcreteAbsiye AdenNo ratings yet

- BOQ Water Proofing With BASF RangeDocument1 pageBOQ Water Proofing With BASF Rangehemantrulz0% (1)

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemQ8123No ratings yet

- Different Types of Concrete - RPC, RMC, LWC, HPC EtcDocument7 pagesDifferent Types of Concrete - RPC, RMC, LWC, HPC Etcm_noorbashaNo ratings yet

- Silica Fume 5 PDFDocument14 pagesSilica Fume 5 PDFNour KottiNo ratings yet

- ANN Paper PDFDocument5 pagesANN Paper PDFEmeso OjoNo ratings yet

- Ojo Et Al PDFDocument8 pagesOjo Et Al PDFEmeso OjoNo ratings yet

- Effect of Mineralogy On Performance Characteristics of CompressedDocument29 pagesEffect of Mineralogy On Performance Characteristics of CompressedEmeso OjoNo ratings yet

- Assessment of Suitability of CSEBDocument7 pagesAssessment of Suitability of CSEBEmeso OjoNo ratings yet

- Laboratory Investigation On Construction Materials From Kubwa Extension Building Collapse Site, AbujaDocument15 pagesLaboratory Investigation On Construction Materials From Kubwa Extension Building Collapse Site, AbujaEmeso OjoNo ratings yet

- Kaolin Lab ReportDocument15 pagesKaolin Lab ReportEmeso OjoNo ratings yet

- Laboratory Investigation On Construction Materials From Kubwa Extension Building Collapse Site, AbujaDocument15 pagesLaboratory Investigation On Construction Materials From Kubwa Extension Building Collapse Site, AbujaEmeso OjoNo ratings yet

- Laboratory Investigation On Construction Materials From Kubwa Extension Building Collapse Site, AbujaDocument15 pagesLaboratory Investigation On Construction Materials From Kubwa Extension Building Collapse Site, AbujaEmeso OjoNo ratings yet

- Geotechnical Properties of Soils From Wukari Taraba StateDocument9 pagesGeotechnical Properties of Soils From Wukari Taraba StateEmeso OjoNo ratings yet

- Enhancing Road Safety in Nigeria Through Innovative Road Design and ConstructionDocument12 pagesEnhancing Road Safety in Nigeria Through Innovative Road Design and ConstructionEmeso OjoNo ratings yet

- NSF Science and Engineering Indicators 2014Document600 pagesNSF Science and Engineering Indicators 2014Adrian ArizmendiNo ratings yet

- VMD-412 9 April 2014Document8 pagesVMD-412 9 April 2014ashish kumarNo ratings yet

- LC OscillationsDocument9 pagesLC OscillationsNaveen BabbarNo ratings yet

- F PortfolioDocument63 pagesF PortfolioMartin SchmitzNo ratings yet

- API DevDocument274 pagesAPI Devruggedboy0% (1)

- Arulanandan Soil Structure PDFDocument251 pagesArulanandan Soil Structure PDFchongptNo ratings yet

- Stone ChapaisDocument6 pagesStone ChapaisMaría GallardoNo ratings yet

- 3D CL Correction S1223RTLDocument7 pages3D CL Correction S1223RTLakatsuki.exeNo ratings yet

- QuickUSB User Guide v2.11.41Document75 pagesQuickUSB User Guide v2.11.41Vport Port100% (1)

- Proposal Kerja PraktekDocument11 pagesProposal Kerja PraktekBilly Dentiala Irvan100% (1)

- Ba101 Engineering Mathematics 1Document21 pagesBa101 Engineering Mathematics 1nurhaiziinovasiNo ratings yet

- UPSC Paper 4 Binder PDFDocument17 pagesUPSC Paper 4 Binder PDFHsis AbedNo ratings yet

- ESL BOOKS - IELTS Academic Writing Task 1 Vocabulary by ESL Fluency - PreviewDocument7 pagesESL BOOKS - IELTS Academic Writing Task 1 Vocabulary by ESL Fluency - Previewanirudh modhalavalasaNo ratings yet

- Procedure To Create The Employee Attendance ProjectDocument30 pagesProcedure To Create The Employee Attendance ProjectSougata Roy Chowdhury0% (5)

- SmartForm - Invoice TutorialDocument17 pagesSmartForm - Invoice TutorialShelly McRay100% (5)

- Manhunt!: Adventure Creation HandbookDocument17 pagesManhunt!: Adventure Creation Handbookmadcap01No ratings yet

- Chemistry Chemical EngineeringDocument124 pagesChemistry Chemical Engineeringjrobs314No ratings yet

- BS 5499-1:2002 Graphical Symbols and Signs - Safety Signs, Including Fire Safety SignsDocument1 pageBS 5499-1:2002 Graphical Symbols and Signs - Safety Signs, Including Fire Safety SignsKuljinder VirdiNo ratings yet

- Natural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFDocument508 pagesNatural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFjcfichte100% (1)

- PV Quick StartDocument61 pagesPV Quick StartMayur PatelNo ratings yet

- 432 HZ - Unearthing The Truth Behind Nature's FrequencyDocument6 pages432 HZ - Unearthing The Truth Behind Nature's FrequencyShiv KeskarNo ratings yet

- Chapter I - Logic and Proofs: PropositionsDocument18 pagesChapter I - Logic and Proofs: PropositionsNênđặttênngắnTêndàiAimàmuốnđọcNo ratings yet

- Innoventure List of Short Listed CandidatesDocument69 pagesInnoventure List of Short Listed CandidatesgovindmalhotraNo ratings yet

- Master SC 2015 enDocument72 pagesMaster SC 2015 enNivas Kumar SureshNo ratings yet

- Exercise of English LanguageDocument2 pagesExercise of English LanguageErspnNo ratings yet

- Peranan Dan Tanggungjawab PPPDocument19 pagesPeranan Dan Tanggungjawab PPPAcillz M. HaizanNo ratings yet

- IO Chapter6 FinalDocument10 pagesIO Chapter6 FinalJulia MoplaNo ratings yet

- Treasure HuntDocument9 pagesTreasure HuntNutsdieyaa ErnieNo ratings yet

- Drim 1201 Classification (Theory and Practice)Document26 pagesDrim 1201 Classification (Theory and Practice)businge innocentNo ratings yet