Professional Documents

Culture Documents

Brick and Plastering

Uploaded by

faroukm91Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brick and Plastering

Uploaded by

faroukm91Copyright:

Available Formats

me : Farooq Mustafa Al-Obaidi

ID: I12001919

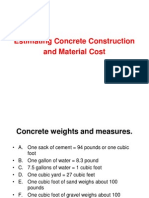

Estimating of unit rate for

brick work

me : Farooq Mustafa Al-Obaidi

ID: I12001919

Brick work

Brickworkismasonryproduced

by

abricklayer,

usingbricksandmortar.

Typically,

rows

of

bricks

calledcoursesare laid on top of one another to build up a

structure such as a brickwall.

Name : Farooq Mustafa Al-Obaidi

ID: I12001919

Number of costs to consider for Brick work

Materials and method of brick order cost

Labor cost

Other costs

Name : Farooq Mustafa Al-Obaidi

Estimating Quantity

Bricks

1. Calculate net surface area of the wall

2. calculate surface area of 1 brick including mortar

3. divide wall area by brick area

4. multiply by number of wythes in wall

5. add an amount for waste

ID: I12001919

e : Farooq Mustafa Al-Obaidi

ID: I12001919

Estimating Quantity

Mortar

Volume per brick =(t)(W)(L+H+t)

t = mortar thickness

W = brick width/depth inches

L = length of brick inches

H = height of brick inches

Add 25% waste

For double wall must add in for mortar in space

e : Farooq Mustafa Al-Obaidi

ID: I12001919

Brick Size

Type

Nominal Size (in)

Actual Size (in)

No. per Square Foot

Standard

4 x 2 2?3 x 8

3 5/8 x 2 1/4 x 8

6.3

Modular

4 x 2 2/3 x 8

3 5/8 x 2 1/4 x 7 5/8

6.9

King

3 3/8 x 3 x 10

3 x 2 5/8 x 9 5/8

4.8

Queen

2 3/4 x 3 x 10

3 1/8 x 2 3/4 x 9 5/8

4.6

Engineer

4 x 3 1/5 x 8

3 5/8 x 2 13/16 x 7 5/8

5.7

Economy

4x4x8

3 5/8 x 3 5/8 x 7 5/8

4.5

Utility

4 x 4 x 12

3 5/8 x 3 5/8 x 11 1/2

3.1

Jumbo

4x3x8

3 5/8 x 2 3/4 x 8

5.5

Norman

4 x 2 2/3 x 12

3 5/8 x 2 1/4 x 11 5/8

4.6

Jumbo Norman

4 x 3 x 12

3 5/8 x 2 3/4 x 11 5/8

Norwegian

3 1/2 x 3 x 12

3 1/2 x 2 3/4 x 11 5/8

3.9

Name : Loh Ming Chong

Common Bricks ( 3 holes )

Dimensions:

215 x 96 x 70 mm

Compressive Strength:

> 25mN/m

Water Absorption:

< 13.7%

Per Pallet:

500 pieces

Common Bricks ( full )

Dimensions:

215 x 96 x 70 mm

Compressive strength:

> 25mN/m

Water absorption:

< 13.5%

Thermal Conductivity:

1.04W/m K

Per Pallet:

500 pieces

ID : I13002638

Name : Loh Ming Chong

ID : I13002638

Mortar Required for Common Bricks

Common bricks - 2 1/4 x8 x 3 3/4 inches:

Joint Thickness

(inches)

Mortar Required(ft3)

per 1000 bricks

per ft3brick

1/4

0.2

3/8

14

0.3

1/2

20

0.4

Name : Loh Ming Chong

ID : I13002638

Types of Mortar

Mortar Grade

Cement : Sand

Masonry

Cement : Lime : Sand

1:3

Cement : Sand

Cement : Sand &

Plasticizer

Typical Compressive Strength,

N/mm2

7 days

8 days

1 : 1/4 : 3

11.0

16.0

1 : 1/2 : 4

1:3

1:4

5.5

8.0

1 : 1 : 5~6

1 : 4

1 : 5~6

2.5

4.0

1 : 2 : 8~9

1:6

1 : 7~8

1.0

1.5

1 : 3 : 10~13

1:7

1:8

Note 1: "Lime" refers to non-hydraulic or semi-hydraulic lime

Note 2: Mixes are measured by ratio in volume

Name : Loh Ming Chong

Brick Bond Laying Patterns

ID : I13002638

Name : Loh Ming Chong

Mortar Joints

ID : I13002638

Name : Loh Ming Chong

Labor Cost

ID : I13002638

Name : Loh Ming Chong

Example

ID : I13002638

Estimating of Unit Rate of

Plastering

Name : Johnson Mwanri

ID: I12000392

What is Plastering?

Plaster is a building material used for coating walls and

ceilings. Plaster is manufactured as a dry powder and is mixed

with water to form a paste when used. The reaction with water

liberates heat through crystallization and the hydrated plaster

then hardens. Plaster can be relatively easily worked with

metal tools or even sandpaper. These characteristics make

plaster suitable for a finishing, rather than a load-bearing

material.

The term plaster can refer to gypsum plaster (also known as

plaster of Paris), lime plaster, or cement plaster.

Name : Johnson Mwanri

Plastering

ID: I12000392

Name : Johnson Mwanri

ID: I12000392

How to Estimate the Unit Rate of

Plastering

Preparing Unit rate for Plastering will require:

Cost of various material which will be used during Plastering

e.g. Portland Cement, Sand, Addictive's and Form works

(Scaffolding).

Cost of Transportation of Material

Costing of Labours which include Skilled (Tradesman's) and

non Skilled

Plant Cost e.g. Concrete Mixer

Overhead and Profit

Name : Johnson Mwanri

ID: I12000392

Summary of Labour Estimation:

Hourly Unit

Total Hour of Tradesman = Total Area of Plastering (m2) x hours rate (e.g 0.2)

Total Cost of Tradesman (Skilled Labour) = Total Hour of Tradesman x Rate per Hour

Add 15% to the Total Cost as Profit

Name : Sunia Baravilala

ID: I13004082

Summary of Labour Estimation:

Days Unit

For 1m3, it will take 0.27days for the Tradesman to finish it

Total Day of Tradesman = Total Volume of Plastering (m3) x 0.27

Total Cost of Tradesman (Skilled Labour) = Total Days of Tradesman x Rate per Day

Add 15% to the Total Cost as Profit

Name : Sunia Baravilala

ID: I13004082

Summary of Labour Estimation:

Days Unit

For 1m3, it will take 0.26days for the Unskilled Labour for carrying

of

cement, sand and water.

Total Days of Unskilled Labours = Total Volume of Plastering (m3) x 0.26

Total Cost of Unskilled Labours = Total Days of Unskilled Labours x Rate per Day

Add 15% to the Total Cost as Profit

Name : Sunia Baravilala

ID: I13004082

Material Estimate Summary:

With reference to the Drawing, the amount of Portland cement and Sand can

be calculated with reference to it thickness needed.

Since there is a lot of in accuracy in estimating of volume of plastering, we consider

factors such as

Wastage

Non uniform of thickness

So we add Add 40% to the Total material Cost to cover these factors

Name : Sunia Baravilala

ID: I13004082

Plant Estimate Summary :

For 1m3, it will take 0.27days for the mechanical mixture to

produce.

Total Days of Mechanical Concrete Mixture = Total m3 of concrete x 0.27

Cost of Mechanical Concrete Machine = Total Days of Mechanical Concrete Mixture x

Rate

Add 15% to the Total Cost as Profit

Name : Sunia Baravilala

ID: I13004082

Transportation and Formworks Estimate Summary :

Mostly it transported by Hoist Trucks they paid in Daily rates

Total Trip of Truck = Total Weight of Material (kg or tonnes )/ The maximum weight the Truck

can carry (kg or tonnes)

Total Days = Total trip of Trucks x total hours for trip(e.g 0.2 days)

Cost of Trucks = Total Days x Rate of truck

Add 15% to the Total Cost as Profit

Name : Sunia Baravilala

ID: I13004082

Transportation and Formworks Estimate

Summary :

Mostly Scaffolding are used for formwork of

Plastering and they paid in Daily rates

Cost of Scaffolding = Total Days x Rate of Scaffolding per Day

Add 15% to the Total Cost as Profit

Name : Sunia Baravilala

ID: I13004082

To Built Unit Rates for Plastering

Unit Rates of Plastering =

Total Cost of Material + Total Cost of Plant + Total Cost of Labours + Total Cost of Transportation

and Formworks / The Total Area of Plastering

Note : That 15% profit is already added to individual items

Name : Sunia Baravilala

ID: I13004082

Malaysian Plastering Unit Rate:

You might also like

- How To Avoid Cracks in PlasterDocument3 pagesHow To Avoid Cracks in PlasterShativel ViswanathanNo ratings yet

- Gypsum PlasterDocument40 pagesGypsum PlasterManish AhujaNo ratings yet

- 1.wall Finishes - PlasteringDocument23 pages1.wall Finishes - PlasteringShafnaFawaz100% (1)

- Types of PlastersDocument21 pagesTypes of PlastersShivam RavalNo ratings yet

- Cement Plaster FinishesDocument16 pagesCement Plaster FinishesRoi de JesusNo ratings yet

- Curing Cement PlasterDocument3 pagesCuring Cement PlasterChristian LlagasNo ratings yet

- Cement PlasteringDocument8 pagesCement PlasteringJanetNo ratings yet

- Polymer Modified Mortars and CementDocument9 pagesPolymer Modified Mortars and CementKunwar Apoorv Singh Parihar100% (1)

- Your Guide To PlasteringDocument8 pagesYour Guide To PlasteringChristopher GeorgeNo ratings yet

- Common Defects in Plaster PDFDocument2 pagesCommon Defects in Plaster PDFraviteja036No ratings yet

- Concrete Technology Module 1 NotesDocument26 pagesConcrete Technology Module 1 NotesDEDAN KIMATHINo ratings yet

- Lime Literature ScribdDocument3 pagesLime Literature ScribdVaishali LatkarNo ratings yet

- National Gypsum Plaster Products (Veneer Systems)Document28 pagesNational Gypsum Plaster Products (Veneer Systems)mtim360No ratings yet

- Water Repellent Cement Paint ProjectDocument9 pagesWater Repellent Cement Paint ProjectSwaroop MnNo ratings yet

- Laboratory Studies On Small Scale Production of Three (3) Different Grades of Emulsion PaintsDocument13 pagesLaboratory Studies On Small Scale Production of Three (3) Different Grades of Emulsion Paintsmohamed sabryNo ratings yet

- Handbook On Comprehensive Guide On Painting For BuildingsDocument41 pagesHandbook On Comprehensive Guide On Painting For BuildingsRohan GoyalNo ratings yet

- 3.materials of Construction PDFDocument10 pages3.materials of Construction PDFSudha kNo ratings yet

- Advance Construction and MaterialsDocument23 pagesAdvance Construction and MaterialsSaki Saki SakiNo ratings yet

- Brick Lecture NotesDocument13 pagesBrick Lecture NoteschinmayihyNo ratings yet

- Building Material - PlasterDocument26 pagesBuilding Material - PlasterSaurav ShresthaNo ratings yet

- EXPANDIT 10 Mortar Comparison TestDocument1 pageEXPANDIT 10 Mortar Comparison TestLaura GarcíaNo ratings yet

- Tiling Over Movement JointsDocument14 pagesTiling Over Movement JointspankajNo ratings yet

- The Feica-Asc Adhesives & Sealants Classification ManualDocument17 pagesThe Feica-Asc Adhesives & Sealants Classification ManualNitin SinghalNo ratings yet

- Floor FinishesDocument20 pagesFloor FinishesFidha SulfiNo ratings yet

- Chapter 10wallfinishesplasteringpointingpainting 180117080527Document61 pagesChapter 10wallfinishesplasteringpointingpainting 180117080527Jude Acepcion100% (1)

- PlasteringDocument15 pagesPlasteringMegha RajNo ratings yet

- PaintsDocument22 pagesPaintsPriyanka BasuNo ratings yet

- Characterisation and Consolidation of Historical Lime Mortars in Cultural Heritage BuildingsDocument130 pagesCharacterisation and Consolidation of Historical Lime Mortars in Cultural Heritage BuildingsIdaHodzicNo ratings yet

- Plastering PointingDocument31 pagesPlastering PointingPageduesca RouelNo ratings yet

- Const PPT Adhesives - Sem3 PDFDocument60 pagesConst PPT Adhesives - Sem3 PDFRiya VermaNo ratings yet

- 7.decorative FinishesDocument28 pages7.decorative FinishesakurilNo ratings yet

- Additives Reference Guide 2013Document80 pagesAdditives Reference Guide 2013Victor MelloNo ratings yet

- Vernacular Building Material - LimeDocument16 pagesVernacular Building Material - LimeShine You100% (1)

- Concrete StampedDocument28 pagesConcrete StampedOlajide AdedamolaNo ratings yet

- Tile Adhesives - Kenya StandardDocument19 pagesTile Adhesives - Kenya StandardChrisNo ratings yet

- Stone FlooringDocument42 pagesStone FlooringVighnesh MalagiNo ratings yet

- Pamphlet On Quality Assurance For Cement PlasteringDocument4 pagesPamphlet On Quality Assurance For Cement PlasteringD V BHASKARNo ratings yet

- Building MaterialsDocument13 pagesBuilding MaterialsPriyanka BasuNo ratings yet

- Goals: I. II. Iii.Document68 pagesGoals: I. II. Iii.ganeshlalkumawatNo ratings yet

- BPD Master Catalogue-2Document18 pagesBPD Master Catalogue-2Dr. Manamohan R KalgalNo ratings yet

- Stucco Italiano - Venetian PlastersDocument37 pagesStucco Italiano - Venetian PlastersClara PolistenaNo ratings yet

- 8 Plastering PDFDocument26 pages8 Plastering PDFZayedur RahmanNo ratings yet

- Venetian Plaster Finishes - Stucco ItalianoDocument17 pagesVenetian Plaster Finishes - Stucco ItalianoClara PolistenaNo ratings yet

- Lime PDFDocument30 pagesLime PDFManish Rawat100% (1)

- To Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao DeshmukhDocument11 pagesTo Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao Deshmukhmukesh poundekarNo ratings yet

- PaintDocument10 pagesPaintkimNo ratings yet

- Chemical AdmixtureDocument9 pagesChemical AdmixtureShenbagaraja PandianNo ratings yet

- Project Report of Fly-Ash Bricks UdyogDocument9 pagesProject Report of Fly-Ash Bricks UdyogVijayNo ratings yet

- Additives Brochure EN Apac 20130801 Page PDFDocument6 pagesAdditives Brochure EN Apac 20130801 Page PDFRatih AriyaniNo ratings yet

- Disadvantages in AAC BlocksDocument3 pagesDisadvantages in AAC BlocksGaurav JainNo ratings yet

- Cultured MarbleDocument9 pagesCultured Marblesaira tahirNo ratings yet

- Gypsum PlasterboardDocument7 pagesGypsum PlasterboardJerusalemsNo ratings yet

- Particle BoardDocument15 pagesParticle BoardYadhu Sankar100% (1)

- Damp Proofing: Presented by Ahsan Rabbani Civil Engineering DepartmentDocument27 pagesDamp Proofing: Presented by Ahsan Rabbani Civil Engineering DepartmentMichael Matshona100% (1)

- PVC Crust Foam Board Manufacture Process ControDocument1 pagePVC Crust Foam Board Manufacture Process ControFrank ZhangNo ratings yet

- Formulation Techniques Using Feve Resins in Waterborne and HighDocument10 pagesFormulation Techniques Using Feve Resins in Waterborne and HighManuel ChireNo ratings yet

- Part 5 TilesDocument8 pagesPart 5 TilesFerdz ValenzNo ratings yet

- Types of PaintsDocument2 pagesTypes of PaintsmariyaNo ratings yet

- Best Hydraulic SectionDocument30 pagesBest Hydraulic Sectionfaroukm9175% (4)

- Gravity Wall Calculator TADocument13 pagesGravity Wall Calculator TAfaroukm91100% (1)

- Estimating Concrete Material Fuller MethodDocument17 pagesEstimating Concrete Material Fuller MethodOliver BrownNo ratings yet

- Brick and Plastering Final EditDocument1 pageBrick and Plastering Final Editfaroukm91No ratings yet

- Gravity CantileverDocument3 pagesGravity Cantileverfaroukm91No ratings yet

- Preliminaries: COMP 523: Advanced Algorithmic Techniques Lecturer: Dariusz KowalskiDocument31 pagesPreliminaries: COMP 523: Advanced Algorithmic Techniques Lecturer: Dariusz Kowalskifaroukm91No ratings yet

- PrecastDocument7 pagesPrecastfaroukm91No ratings yet

- PrecastDocument7 pagesPrecastfaroukm91No ratings yet

- Georgios Yannoussis Maturity of InfrastDocument13 pagesGeorgios Yannoussis Maturity of Infrastfaroukm91No ratings yet

- 3 Phase ModelsDocument24 pages3 Phase Modelsfaroukm91No ratings yet

- 1635 PDFDocument7 pages1635 PDFKaushal KishoreNo ratings yet

- CONCRETE QUIZ 2019 Full QP - EditedDocument25 pagesCONCRETE QUIZ 2019 Full QP - EditedRajha RajeswaranNo ratings yet

- Typical Methods of Moisture Intrusion: Little Pigs? The Big Bad Wolf Blew The StickDocument8 pagesTypical Methods of Moisture Intrusion: Little Pigs? The Big Bad Wolf Blew The StickaliNo ratings yet

- Is 4139 1989 PDFDocument12 pagesIs 4139 1989 PDFSwagato ChakrobortyNo ratings yet

- Brick: History of BricksDocument11 pagesBrick: History of BricksKrutiGDesaiNo ratings yet

- Cement Industry: Manufacturing Process of Portland Cement Raw MaterialsDocument11 pagesCement Industry: Manufacturing Process of Portland Cement Raw Materialsد.حاتممرقهNo ratings yet

- Civil Engineering: Construction MaterialsDocument16 pagesCivil Engineering: Construction MaterialsNishanth BnNo ratings yet

- Moisture Influence On Compressive Strength of Ternary Gypsum-Based BindersDocument5 pagesMoisture Influence On Compressive Strength of Ternary Gypsum-Based BindersIS AANo ratings yet

- Construction of Hill Roads and AnswersDocument67 pagesConstruction of Hill Roads and AnswersIqbal BaigNo ratings yet

- SPECIFICATIONDocument25 pagesSPECIFICATIONkingcedsNo ratings yet

- Building MaterialsDocument13 pagesBuilding MaterialsDeeana MoraaNo ratings yet

- Vernacular Building Material - LimeDocument16 pagesVernacular Building Material - LimeShine You100% (1)

- CHAPTER 2 of Thesis On Stabilization RahulDocument5 pagesCHAPTER 2 of Thesis On Stabilization RahulSanjay TiwariNo ratings yet

- Bricks Presentation (By G Dhar)Document81 pagesBricks Presentation (By G Dhar)Glistering Dhar100% (1)

- DPWH Standard Specification On Aggregate Sub Base CourseDocument4 pagesDPWH Standard Specification On Aggregate Sub Base CourseLance LanceNo ratings yet

- Cinnamon BoutiqueDocument22 pagesCinnamon BoutiqueArul Dhas100% (1)

- Kessem Final PresentationDocument43 pagesKessem Final PresentationShasho LikisaNo ratings yet

- Applicability of Biodegradable Fibres On The Geotechnical Properties of A Subgrade MaterialDocument18 pagesApplicability of Biodegradable Fibres On The Geotechnical Properties of A Subgrade MaterialHAMPO OBINNANo ratings yet

- Evaluating of Rutting in Highways & Providing Its Solution in Terms of Stone Matrix Asphalt.Document7 pagesEvaluating of Rutting in Highways & Providing Its Solution in Terms of Stone Matrix Asphalt.IJRASETPublications100% (1)

- T81 Rep Kriya Med Oragadam 140215Document32 pagesT81 Rep Kriya Med Oragadam 140215VasanthakumarNo ratings yet

- 2000 Hauptmann and Yalcin PlasterDocument9 pages2000 Hauptmann and Yalcin PlasterMarijana JakovljevicNo ratings yet

- Chapter - 6 - BricksDocument56 pagesChapter - 6 - BricksPutry JazmeenNo ratings yet

- JODHPUR INDUSTRIES ASSOCIATION - Brief NoteDocument6 pagesJODHPUR INDUSTRIES ASSOCIATION - Brief NoteVikas SharmaNo ratings yet

- Chapter 3Document12 pagesChapter 3Markos MikoNo ratings yet

- Pavement Design Manual Volume I Flexible Pavements Converted 1Document294 pagesPavement Design Manual Volume I Flexible Pavements Converted 1Dani Man100% (2)

- Asphalt Foamed MixDocument13 pagesAsphalt Foamed MixCristian OJNo ratings yet

- HB 161-2005 Guide To PlasteringDocument10 pagesHB 161-2005 Guide To PlasteringSAI Global - APAC0% (2)

- Brick Lecture by Md. Mahfujur RahmanDocument28 pagesBrick Lecture by Md. Mahfujur RahmanAbdul Majet MohamedNo ratings yet

- Chapter 6 BricksDocument56 pagesChapter 6 BricksDdeqz Elina Bueno I100% (1)

- Naurang Yatri Niwas FinalDocument18 pagesNaurang Yatri Niwas FinalRiddhi Aggarwal100% (3)