Professional Documents

Culture Documents

Effects of CO On Growth

Uploaded by

John Paul RodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of CO On Growth

Uploaded by

John Paul RodriguezCopyright:

Available Formats

Effects of CO2 on Growth

Effects of CO2 on Growth

At ambient aeration (0.036% CO2), the pH of the algal

cultures were observed to rise in the range 7.79-8.73

CO2 enriched aeration caused the pH of the medium to

decrease which in effect causing downward shift of pH

between 7.0-6.0

at 1% CO2 aeration, the pH of the culture at day 7 were

observed to rise to 7.35-7.60

then after day 14 the pH was observed to shift

downward; at 3% CO2 aeration, the pH of the culture

gradually shift downward at day 7 between 7.00-6.79.

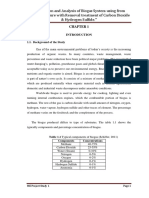

Effects of CO2 on Growth

pH range at different conditions of Fe3+ and CO2

concentration

% CO

Fe (M)

pH Range

Ave pH

Dbm(mg/L)

3+

2.40E-05

0.036

7.90-8.73

8.320.07

6826.4575

4.80E-05

0.036

7.79-8.68

8.240.07

12070

9.60E-05

0.036

7.80-8.70

8.330.04

136.6740.4145

2.40E-05

7.95-7.24

7.460.02

143.3375.7188

4.80E-05

8.10-7.18

7.480.01

163.3320

9.60E-05

7.92-7.15

7.480.05

203.3323.0940

2.40E-05

8.00-6.90

7.220.01

246.6781.4453

4.80E-05

7.88-6.79

7.140.03

263.3358.5947

9.60E-05

7.95-6.80

7.190.01

19065.5744

Effects of CO2 on Growth

the gradual decrease of average pH of the culture towards neutrality

significantly resulted in the increase of the growth of the algal

culture.

There is also relation to the production of chlorophyll a, which is the

important energy capture portion of algae.

production of chlorophyll a, which is the important energy capture

portion of algae. Base on the results conducted by Lewandowska and

Kosakowska (2004), there is a significant decrease in the production

of chlorophyll a when there is iron-starvation in each algal culture

There is also a pH range, specifically 8.1-7.4, in which suggest an

increase of Fe solubility at about 40% (Breitbarth, Bellerby, Neill,

Ardelan, Meyerhofer, Zollne, Croot & Riebesell4, 2010).

Effects of CO2 on Growth

Dry biomass yield of C. vulgaris under various growth

condition

Effects of CO2 on Growth

algal cultures in the same concentration of Fe (2.4E-05,

4.8E-05 and 9.6E-05) exhibited higher growths, in terms

of dry biomass, in almost all the higher levels of

concentrations for CO2 (1% and 3%) than that of the

ambient CO2 (0.036%).

The growth in 1% CO2 compared to that of 0.036% CO2

were consistently and significantly higher by 26.552.6%, and the culture in 3% CO2 had a higher growth

than that of 1% CO2 for both 2.4E-05 and 4.8E-05 Fe

concentrations by 38-41.9%.

the culture in 9.6E-05 Fe had shown lower growths in

Effects of CO2 on Growth

Elevated CO2 concentration drives a decrease in pH

level which allows easy uptake of CO2 which benefits

the algal growth due to an increase in the availability of

CO2 for carbon uptake

Even with this, the algal culture in 9.6E-05 Fe with 3%

CO2 concentration did not conform to the trend of

having higher dry biomass than those in the lower CO2.

Fatty acid composition of oil extracted from

C. vulgaris, grown under different

concentration of Fe and CO2

0.0326%CO

0.036%CO2 2

0.036%CO2 1%CO2

3%CO2

3%CO2

4.8E-05

Fatty Acid Profile, %w/w

2.4E-05 Fe 4.8E-05 Fe 9.6E-05 Fe 2.4E-05 Fe 4.8E-05 Fe 9.6E-05 Fe 2.4E-05 Fe Fe

9.6E-05 Fe

Butyric (C4)

9.32

7.31

9.32

3.39

1.31

0

0

0

0

Caprylic (C8)

3.61

4.28

1.71

1.67

0.737

1.19

3.44

4.55

6.05

Capric (C10)

4.22

4

1.91

1.77

0.951

1.22

3.12

4.12

5.09

Lauric (C12)

4.61

4.98

9.17

5.64

3.43

6.93

0

0

0.675

Myristic (C14)

8.51

10.8

15.6

8.78

8.64

8.34

5.9

8.01

7.68

Pentadecanoic (C15)

0

0

0

0.606

0

0

0

Palmitic (C16)

17.1

16.7

18.5

15.2

16

16.8

16.1

14.9

14.5

Palmitoleic (C16:1)

2.89

0

2.83

0

0

1.9

1.81

1.16

2.2

Heptadecanoic (C17)

0

0

0

0

0

0.775

0

0

0

Stearic (C18)

1.8

2.66

4.54

2.94

2.27

3.79

0.469

0.627

0.477

Elaidic (C18:1n9t)

4.98

4.97

3.27

5.61

5.69

1.78

6.14

6.95

5.99

Oleic (C18:1)

8.98

7.64

11.3

13.4

10.7

22.4

2.83

3.35

3.41

Linoleic (C18:2)

24.1

23.3

18.1

25.4

31.2

24

34.2

33.9

31.6

cis-11-Eicosenoic (C20:1)

0

0

0

0

0

0.411

0

0

0

Linolenic (C18:3)

22.3

20.9

13.7

19.7

20.5

7.26

26

23.4

24.6

cis-11,14-Eicosadienoic (C20:2)

0

0

0

0

0

0.288

0

0

0

Arachidonic (C20:4)

0

0

0

0

0

0.352

0

0

0

cis-4,7,10,13,16,19-Docosahexaenoic (C22:6)

0

0

0

0

0

1.42

0

0

0

112.42

107.54

109.95

103.5

1%CO2

101.428

1%CO2

99.462

3%CO2

100.009

100.967

102.272

Fatty acid composition of oil extracted from

C. vulgaris, grown under different

concentration of Fe and CO2

Among the fatty acids, the palmitic (C16), linoleic

(C18:2) and linolenic acid (C18:3) were identified as

dominant constituents for all culture conditions.

The results also showed that the relative amount of

these fatty acid as saturated (SFA), mono-unsaturated

(MUFA) and poly-unsaturated (PUFA) had changed

significantly from 29.029-60.75%, 10.78-26.491% and

31.8-60.2%, respectively.

You might also like

- Biological Desulfurization The MBRDocument8 pagesBiological Desulfurization The MBRtaufany99100% (1)

- Royal Society Proceedings of The Royal Society of London. Series B, Containing Papers of A Biological CharacterDocument23 pagesRoyal Society Proceedings of The Royal Society of London. Series B, Containing Papers of A Biological CharacterGamma KnifeNo ratings yet

- Technical Design For Anaerobic Treatment SystemsDocument63 pagesTechnical Design For Anaerobic Treatment SystemskuthappadyNo ratings yet

- Crop Response To Elevated Carbpn DioxydDocument5 pagesCrop Response To Elevated Carbpn DioxydLai azeNo ratings yet

- Pyrolysis of Rice Husk Hidayat 200223Document12 pagesPyrolysis of Rice Husk Hidayat 200223Aditya RinaldiNo ratings yet

- Acid Rain in Distilleries in Pakistan: AbstractDocument3 pagesAcid Rain in Distilleries in Pakistan: AbstractQasim ShahzadNo ratings yet

- FACE Article (Nature)Document5 pagesFACE Article (Nature)Minh Tue NGUYENNo ratings yet

- Kronos Ecochem Ti 5 - 01 - enDocument4 pagesKronos Ecochem Ti 5 - 01 - enDennis LingNo ratings yet

- Anaerobic Treatment (PPT) - (Part - I) 19-03-2013Document24 pagesAnaerobic Treatment (PPT) - (Part - I) 19-03-2013Gaurav Tanwer100% (1)

- Chapter 1 - 1 PDFDocument7 pagesChapter 1 - 1 PDFShayNo ratings yet

- 13-039 Growth Nitrogen Utilization A1bDocument16 pages13-039 Growth Nitrogen Utilization A1bClaudia UngureanuNo ratings yet

- Anaerobic Treatment Systems Technical DesignDocument64 pagesAnaerobic Treatment Systems Technical DesignJizzlmanizzlNo ratings yet

- Algae To Energy - PowerpointDocument24 pagesAlgae To Energy - PowerpointjkhrashprashNo ratings yet

- 422 NR Factors in NitrificationDocument3 pages422 NR Factors in NitrificationElena Iulia CucoleaNo ratings yet

- Biogas Cleaning and Upgrading Technologies - OhiolineDocument6 pagesBiogas Cleaning and Upgrading Technologies - Ohiolinebhuneshwar paswanNo ratings yet

- Algae ConceptDocument9 pagesAlgae ConceptAnand RSNo ratings yet

- Anaerobic Processes (Chapter 10) : AdvantagesDocument13 pagesAnaerobic Processes (Chapter 10) : AdvantagesΔημητρηςΣαρακυρουNo ratings yet

- BiogasDocument60 pagesBiogasFahim TanvirNo ratings yet

- High Atmospheric Carbon Dioxide-Dependent AlleviatDocument14 pagesHigh Atmospheric Carbon Dioxide-Dependent AlleviatJAN CAMILLE OLIVARESNo ratings yet

- WHO Air QT Guidelines Nitrogen DioxideDocument33 pagesWHO Air QT Guidelines Nitrogen DioxidesusCitiesNo ratings yet

- Anaerobic Digestion Basics: Lide Chen and Howard NeiblingDocument4 pagesAnaerobic Digestion Basics: Lide Chen and Howard NeiblingAdhe Iermha SuryanieNo ratings yet

- Laboratory Tests For Waste WaterDocument8 pagesLaboratory Tests For Waste WaterAli Naveed FarookiNo ratings yet

- Mixing A Balanced Nutrient SolutionDocument16 pagesMixing A Balanced Nutrient SolutionRómulo Del ValleNo ratings yet

- Application of The Central Composite Design and Response Surface Methodology To The Advanced Treatment of Olive Oil Processing Wastewater Using Fenton's PeroxidationDocument9 pagesApplication of The Central Composite Design and Response Surface Methodology To The Advanced Treatment of Olive Oil Processing Wastewater Using Fenton's PeroxidationBEANNo ratings yet

- 25.2.2.12. Volatile Solids and CODDocument5 pages25.2.2.12. Volatile Solids and CODSebastian Sanchez PolancoNo ratings yet

- Study On Biogas Production Ofjoint Anaerobic Digestion With Excess Sludge and Kitchen WasteDocument7 pagesStudy On Biogas Production Ofjoint Anaerobic Digestion With Excess Sludge and Kitchen WasteShiva KumarNo ratings yet

- Biogas and Biodigesters 2Document70 pagesBiogas and Biodigesters 2Giovani de MoraisNo ratings yet

- 25.000 M3 AAT de Çamurun Ozonla Azaltımı-Fabiyi2008Document11 pages25.000 M3 AAT de Çamurun Ozonla Azaltımı-Fabiyi2008yusuf yeniceNo ratings yet

- Removal of CO From Biogas Plant Using Chemical Absorption ColumnDocument7 pagesRemoval of CO From Biogas Plant Using Chemical Absorption ColumnanirudhNo ratings yet

- Aggregation of Sulphate-Reducing Bacteria and Homo-Acetogenic Bacteria in A Lab-Scale Gas-Lift ReactorDocument6 pagesAggregation of Sulphate-Reducing Bacteria and Homo-Acetogenic Bacteria in A Lab-Scale Gas-Lift ReactorBernadeth MoralesNo ratings yet

- Bioremediation of Oil-Contaminated SitesDocument58 pagesBioremediation of Oil-Contaminated SitesPrince KumarNo ratings yet

- 4.2 Oxygen Demand and Kinetics 2Document31 pages4.2 Oxygen Demand and Kinetics 2Scott MuthuriNo ratings yet

- Fats Oil and Grease (FOG) Treatment in Grease Converters Using BioadditivesDocument12 pagesFats Oil and Grease (FOG) Treatment in Grease Converters Using BioadditivesAria MandalikaNo ratings yet

- 1-The Biological BasisDocument3 pages1-The Biological BasisCatalina RobertoNo ratings yet

- Biogas: Sources, Purification and Uses: Martín Ramírez J. M. GómezDocument29 pagesBiogas: Sources, Purification and Uses: Martín Ramírez J. M. GómezDian AlbertoNo ratings yet

- Lipid Production From Microalgae As A Promising Candidate For Biodiesel ProductionDocument5 pagesLipid Production From Microalgae As A Promising Candidate For Biodiesel ProductionIndah ApriantiNo ratings yet

- Jurnal 10Document17 pagesJurnal 10Daniall AbdanNo ratings yet

- Scientific ReportDocument6 pagesScientific Reportapi-334750388No ratings yet

- Energies 12 02473Document16 pagesEnergies 12 02473Andry SianturiNo ratings yet

- Water 11 01849Document17 pagesWater 11 01849Khaled NaguibNo ratings yet

- Bioreactorbasis 140427133731 Phpapp01 1xgp85mDocument59 pagesBioreactorbasis 140427133731 Phpapp01 1xgp85mElizabeth XimenaNo ratings yet

- Sulfur and Hydrogen Sulfide RecoveryDocument27 pagesSulfur and Hydrogen Sulfide RecoveryChemical.AliNo ratings yet

- Biology Form and Function - Interpreting DataDocument3 pagesBiology Form and Function - Interpreting DatamasasakiNo ratings yet

- Environmental Pollution: SciencedirectDocument12 pagesEnvironmental Pollution: SciencedirectMonnierNo ratings yet

- Determining Compost MaturityDocument6 pagesDetermining Compost MaturityRonalit MalintadNo ratings yet

- BioDocument25 pagesBioKedar Singh ThakuriNo ratings yet

- CROPS Paper FinalDocument8 pagesCROPS Paper FinalGregory BenfordNo ratings yet

- W1 USIL Group RetamozoDocument10 pagesW1 USIL Group RetamozoDante AngelNo ratings yet

- Lettuce Production in Aquaponic and Hydroponic Systems: Ágota Kovácsné Madar, Tímea Rubóczki, Mária Takácsné HájosDocument9 pagesLettuce Production in Aquaponic and Hydroponic Systems: Ágota Kovácsné Madar, Tímea Rubóczki, Mária Takácsné HájosMirela CrețuNo ratings yet

- EPM White Paper FermentationDocument5 pagesEPM White Paper FermentationJason WangNo ratings yet

- Artikel 1Document6 pagesArtikel 1iimcaemdwNo ratings yet

- Aerobic Treatment FAQsDocument4 pagesAerobic Treatment FAQsvince6111No ratings yet

- Research ArticleDocument12 pagesResearch ArticlePranavNo ratings yet

- Algae Technology Report: IndexDocument20 pagesAlgae Technology Report: IndexSteve RacoosinNo ratings yet

- Leach AteDocument23 pagesLeach AteMykai CucNo ratings yet

- LPG Merox UnitDocument5 pagesLPG Merox Unitsem75% (4)

- BOD and COD RemovalDocument13 pagesBOD and COD Removaldesireeh200950% (2)

- AINSWORTH-2008 - Rice Production in A Changing Clim.Document9 pagesAINSWORTH-2008 - Rice Production in A Changing Clim.Marcela LúciaNo ratings yet

- AGF Potato ProcessingDocument8 pagesAGF Potato Processinganil_049No ratings yet

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationFrom EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNo ratings yet

- PhysicsDocument2 pagesPhysicsJohn Paul RodriguezNo ratings yet

- Biofuels From Algae For Sustainable DevelopmentDocument8 pagesBiofuels From Algae For Sustainable DevelopmentJohn Paul RodriguezNo ratings yet

- Algebra-Problem With SolutionsDocument7 pagesAlgebra-Problem With SolutionsJohn Paul RodriguezNo ratings yet

- COmputer Applications in Practicing EngineerDocument1 pageCOmputer Applications in Practicing EngineerJohn Paul RodriguezNo ratings yet

- Microalgal Species in The Modern TimesDocument13 pagesMicroalgal Species in The Modern TimesJohn Paul RodriguezNo ratings yet

- Water Values at Different ConcentrationDocument2 pagesWater Values at Different ConcentrationJohn Paul RodriguezNo ratings yet

- Computer Application in ChEDocument11 pagesComputer Application in ChEJohn Paul RodriguezNo ratings yet

- Plans For New Reactors Worldwide As 2015 (LECTURE2015)Document7 pagesPlans For New Reactors Worldwide As 2015 (LECTURE2015)John Paul RodriguezNo ratings yet

- Size ReductionDocument12 pagesSize ReductionJohn Paul RodriguezNo ratings yet

- SedimentationDocument3 pagesSedimentationJohn Paul Rodriguez100% (1)

- Gas AbsorptionDocument14 pagesGas AbsorptionJohn Paul RodriguezNo ratings yet

- Computer Application in ChEDocument12 pagesComputer Application in ChEJohn Paul RodriguezNo ratings yet

- Single Page Integral Table PDFDocument2 pagesSingle Page Integral Table PDFMehmet Helva100% (2)

- Biology of AlgaeDocument10 pagesBiology of AlgaeJohn Paul RodriguezNo ratings yet

- Biochem 2 - Introduction To MetabolismDocument20 pagesBiochem 2 - Introduction To MetabolismJohn Paul RodriguezNo ratings yet

- Resistance TrainingDocument2 pagesResistance Trainingapi-290154508No ratings yet

- Experimental Data DiffusivityDocument2 pagesExperimental Data DiffusivityJohn Paul RodriguezNo ratings yet

- Schematic Diagram PDFDocument1 pageSchematic Diagram PDFJohn Paul RodriguezNo ratings yet

- Iron 1Document5 pagesIron 1John Paul RodriguezNo ratings yet

- cs5 2ch1Document60 pagescs5 2ch1sitipertiwiNo ratings yet

- Muscular Strength Endurance ActivityDocument4 pagesMuscular Strength Endurance ActivityJohn Paul RodriguezNo ratings yet

- # Eccentric Resistance ExerciseDocument2 pages# Eccentric Resistance Exercisesalva1310No ratings yet

- Muscular Strength Endurance ActivityDocument4 pagesMuscular Strength Endurance ActivityJohn Paul RodriguezNo ratings yet

- Beginner To Advanced Workout ProgramDocument0 pagesBeginner To Advanced Workout ProgramMuhammad AustinNo ratings yet

- Rankine Cycle ProblemDocument2 pagesRankine Cycle ProblemJohn Paul RodriguezNo ratings yet

- Balik-Manggagawa Informat Ion Sheet: Appointment Date: March 27, 2015 02:00 PMDocument1 pageBalik-Manggagawa Informat Ion Sheet: Appointment Date: March 27, 2015 02:00 PMJohn Paul RodriguezNo ratings yet

- Metodo de WilsonDocument8 pagesMetodo de WilsonJavier MeloNo ratings yet

- PumpDocument8 pagesPumpJohn Paul RodriguezNo ratings yet

- Thermodynamics II: ExergyDocument23 pagesThermodynamics II: ExergyJohn Paul RodriguezNo ratings yet

- CBSE Class 11 Business Studies Important Questions Internal TradeDocument4 pagesCBSE Class 11 Business Studies Important Questions Internal TradeAryan Dev SinghNo ratings yet

- G12 Pol Sci Syllabus FinalDocument8 pagesG12 Pol Sci Syllabus FinalChrisjohn MatchaconNo ratings yet

- Complaint Affidavit Rape CaseDocument3 pagesComplaint Affidavit Rape CaseMa Krissa Ellaine Bundang100% (1)

- Dog Bite 5-2cDocument16 pagesDog Bite 5-2cadonijah stonlincolnNo ratings yet

- Dalisay vs. SSS - Action To Quiet Title - Dacion en PagoDocument28 pagesDalisay vs. SSS - Action To Quiet Title - Dacion en PagohlcameroNo ratings yet

- Danelia Testbanks Quiz 2345Document46 pagesDanelia Testbanks Quiz 2345Tinatini BakashviliNo ratings yet

- NCERT Solutions For Class 6 History Chapter 7 Ashoka The Emperor Who Gave Up WarDocument3 pagesNCERT Solutions For Class 6 History Chapter 7 Ashoka The Emperor Who Gave Up Warunofficialbyakugun050100% (1)

- G O Ms NoDocument2 pagesG O Ms NoMuralidhar MogalicherlaNo ratings yet

- UML Diagrams Inventory Management SystemDocument10 pagesUML Diagrams Inventory Management SystemSyed Adnan FaroghNo ratings yet

- Labor Relations Final ExaminationDocument12 pagesLabor Relations Final ExaminationKathNo ratings yet

- People of The Philippines Vs BasmayorDocument2 pagesPeople of The Philippines Vs BasmayorjbandNo ratings yet

- Chapter 4 - TaxesDocument28 pagesChapter 4 - TaxesabandcNo ratings yet

- Week 4 & 5 DDG (Designing Channel Networks)Document32 pagesWeek 4 & 5 DDG (Designing Channel Networks)Aqib LatifNo ratings yet

- Financial Policy For IvcsDocument11 pagesFinancial Policy For Ivcsherbert pariatNo ratings yet

- Religion 345, Presidents of The Church Student ManualDocument300 pagesReligion 345, Presidents of The Church Student ManualRoberto Gogoni100% (1)

- CRPC MergedDocument121 pagesCRPC MergedNishal KiniNo ratings yet

- Environmental Politics Research Paper TopicsDocument7 pagesEnvironmental Politics Research Paper Topicszeiqxsbnd100% (1)

- Rosary Meditations ShortDocument6 pagesRosary Meditations ShortthepillquillNo ratings yet

- CEIL Engineers Annexure ADocument2 pagesCEIL Engineers Annexure AZeeshan PathanNo ratings yet

- Mita Lifestyle Agenda ContentDocument263 pagesMita Lifestyle Agenda Contentnacentral13517No ratings yet

- Classification of Malnutrition in ChildrenDocument2 pagesClassification of Malnutrition in ChildrenJai Jai MaharashtraNo ratings yet

- Republic V Tanyag-San JoseDocument14 pagesRepublic V Tanyag-San Joseyannie11No ratings yet

- Ramya Pabbisetti: Consultant, OAS - UHG - IIM IndoreDocument2 pagesRamya Pabbisetti: Consultant, OAS - UHG - IIM IndoreJyotirmoy GhoshNo ratings yet

- Pointers For FinalsDocument28 pagesPointers For FinalsReyan RohNo ratings yet

- Cyberjaya: Name: Ainira Binti Muhasshim DATE: 18 MAY 2015Document11 pagesCyberjaya: Name: Ainira Binti Muhasshim DATE: 18 MAY 2015reenNo ratings yet

- The Construction of Nationality in Galician Rus enDocument61 pagesThe Construction of Nationality in Galician Rus enpsgdyrwnomail.infoNo ratings yet

- Lesson 1 Learning History What Is History?Document12 pagesLesson 1 Learning History What Is History?林レッシアNo ratings yet

- OPEN For Business Magazine June/July 2017Document24 pagesOPEN For Business Magazine June/July 2017Eugene Area Chamber of Commerce CommunicationsNo ratings yet

- Our Official Guidelines For The Online Quiz Bee Is HereDocument3 pagesOur Official Guidelines For The Online Quiz Bee Is HereAguinaldo Geroy JohnNo ratings yet

- Eugene Cheng - Fulfilling The Duty of Full and Frank Disclosure in The Arrest of ShipsDocument26 pagesEugene Cheng - Fulfilling The Duty of Full and Frank Disclosure in The Arrest of ShipsVũ LýNo ratings yet