Professional Documents

Culture Documents

Kanban System Optimization

Uploaded by

Ambili K C0 ratings0% found this document useful (0 votes)

44 views10 pageskanban system based on inventory management

Original Title

kanban-

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentkanban system based on inventory management

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views10 pagesKanban System Optimization

Uploaded by

Ambili K Ckanban system based on inventory management

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 10

OPERATIONS MANAGEMENT

TOPIC: KANBAN SYSTEM

Submitted To: Submitted By:

Alex Kuruvila Ambili.K.C

Assistant Professor

KANBAN SYSTEM

The kanban system was introduced in 1950 at

Toyota by Taiichi Ohno.

A kanban system is a system of inventory and

production control which uses kanbans as the

principle information transmission devices.

Kan means card and Ban means signal.

kanban is referred to the card along with boxes or

craters used to transport materials or semi finish

components from one workstation to another, in the

product line.

Thecomponents are moved only when needed (on

demand) by the next stations, such that there is no

waiting of parts for operation or further movement.

Two work centres A&B. Work centre A produces a

part that is kept in a bin. Work centre B uses the

parts from that bin. When the bin gets empty, its is a

signal for work centre A to refill it. This empty bin is

the Kanban signal.

EXAMPLE

Company A buys parts at the rate of 1000 per

day; these are delivered in container, each carrying

50 parts, i.e., 20 container per day. The supplier

makes one delivery per day. The truck leaves his

premises at 9 AM, delivers them at noon and

returns to the supplier by evening.

This means supplier should be getting ready

1000 parts for supply the next day. There should

also be empty containers available at the suppliers

factory by the evening of the previous day.

TWO CARD KANBAN SYSTEM

1. MOVE CARD :-

To authorize the movement of parts from one work

centre to the next.

2.PRODUCTION CARD:-

To authorize the production of parts by the work centre.

Toyota uses two card Kanban system,

has its own inbound and outbound

material storage area.

Inbound Stock Area

Outbound Stock Area.

PROBLEM

Bryant Electronics produces short runs of battery-

powered pocket lanterns. You have been asked to

reduce inventory by introducing a kanban system.

After several hours of analysis you have developed the

following data for connectors used in one work cell.

How many kanbans do you need for this connector?

Daily demand 1,500 units

Production lead-time 1 day

Safety stock 1 day

Kanban size 250 units

SOLUTION:

Demand during lead time=1500

Safety stock =1500

Therefore: Maximum inventory level

=1500+1500=3000

Number of kanbans needed

=maximum inventory level/kanban size

=3000/250

=12

RULES OF KANBAN OPERATION

The kanban must always be attached to the product.

Withdrawal of a product should never occur unless a

kanban is attached.

The part should be produce according to the

information provided on the kanban.

If no kanban is attached to be product, there should

not be any production function carried out.

In the event that defective items are produced they

should be not transferred to the subsequent process.

It should be assured that only 100% quality parts

are placed in the container available for use.

ADVANTAGES OF KANBAN SYSTEM

Eliminate waste or scrape and reduce costs.

Design workstations to create mutual trust and support

among humans beings.

Design workstations to adapt and respond to change quickly.

Promote archiving and assuring quality improvement.

Over production is avoided.

It respond quickly to increase or decrease in demands.

Defective parts are isolated and move out of line.

THANK YOU

You might also like

- Kanban: Presented byDocument12 pagesKanban: Presented byshrutesNo ratings yet

- Kanban AssignmentDocument12 pagesKanban AssignmentআশরাফুলইসলামNo ratings yet

- Kanban SystemDocument4 pagesKanban Systemvvns4519888No ratings yet

- Kanban Signaling: Company ConfidentialDocument57 pagesKanban Signaling: Company ConfidentialEldori1988No ratings yet

- Overview On Kanban Methodology and Its ImplementationDocument4 pagesOverview On Kanban Methodology and Its Implementationlaukik_rautNo ratings yet

- Inventory Planning: Nazmun NaharDocument29 pagesInventory Planning: Nazmun NaharKamrulHassanNo ratings yet

- 2-Bin Replenishment Pull System OverviewDocument22 pages2-Bin Replenishment Pull System OverviewLipid BergerNo ratings yet

- Storyboard TemplateDocument11 pagesStoryboard Templateapi-510798383No ratings yet

- Presentation On Lean Manufacturing: Course Title: Ergonomics and Productivity Engineering Sessional Course Code: IPE 3202Document26 pagesPresentation On Lean Manufacturing: Course Title: Ergonomics and Productivity Engineering Sessional Course Code: IPE 3202Ayman Sajjad AkashNo ratings yet

- Report KanbanDocument28 pagesReport KanbanNadaNo ratings yet

- 5S Technique DataDocument9 pages5S Technique DataMuhammad Luqman FarooquiNo ratings yet

- What Is Kanban?Document17 pagesWhat Is Kanban?Andrés AvilésNo ratings yet

- Differentiate Between Supplier Positioning Model and Supplier Preferencing ModelDocument4 pagesDifferentiate Between Supplier Positioning Model and Supplier Preferencing ModelSharon ZweiNo ratings yet

- Lean and Kanban-Based: Software DevelopmentDocument42 pagesLean and Kanban-Based: Software Developmentanafc1403No ratings yet

- Compound Machine ReportDocument9 pagesCompound Machine Reportapi-300746898No ratings yet

- WCM Logistics/Customer Service Pillar: Kanban ImplementationDocument10 pagesWCM Logistics/Customer Service Pillar: Kanban ImplementationFranciele BorgesNo ratings yet

- Communications PlanDocument39 pagesCommunications Planapi-541262602No ratings yet

- Process of EB, QB Samples ShipmentDocument9 pagesProcess of EB, QB Samples ShipmentBự BụngNo ratings yet

- QFD and House of Quality Guide for Designing a RefrigeratorDocument38 pagesQFD and House of Quality Guide for Designing a Refrigeratorshule1No ratings yet

- Improve Work FormDocument4 pagesImprove Work FormambicaNo ratings yet

- Kanban SystemsDocument10 pagesKanban SystemsZeeshange100% (1)

- Assembly LinesDocument34 pagesAssembly LineshabtamuNo ratings yet

- 06 FacilityLayoutDocument62 pages06 FacilityLayoutmanyuenpddNo ratings yet

- MeasureDocument51 pagesMeasureAshwani KumarNo ratings yet

- Aggregate Planning OPCDocument20 pagesAggregate Planning OPCMaithili PrabhuNo ratings yet

- 1 Lean GlossaryDocument7 pages1 Lean GlossaryHilalAldemirNo ratings yet

- Measuring Defect Levels and Calculating Process YieldDocument16 pagesMeasuring Defect Levels and Calculating Process YieldDiego FloresNo ratings yet

- Kanban Replenishment SystemDocument57 pagesKanban Replenishment SystemSaravananNo ratings yet

- How To Write A Great Corporate Social Responsibility ReportDocument11 pagesHow To Write A Great Corporate Social Responsibility Reportasma246No ratings yet

- Arena TutorialDocument8 pagesArena TutorialCoxa100NocaoNo ratings yet

- Sec 04 Quality Control ProcessDocument37 pagesSec 04 Quality Control Processapi-3699912No ratings yet

- AristocratDocument38 pagesAristocratTiến ThànhNo ratings yet

- Warehouse InductionDocument47 pagesWarehouse InductionThrungNo ratings yet

- SampleDocument2 pagesSamplehemilNo ratings yet

- Reorder Point & Safety StockDocument14 pagesReorder Point & Safety StockZermeena KhanNo ratings yet

- Focused Improvement: Prepared By: Lamis Essam El-Sayed Taghreed El-Sayed NayelDocument26 pagesFocused Improvement: Prepared By: Lamis Essam El-Sayed Taghreed El-Sayed NayelLamis EssamNo ratings yet

- What Is QFD?: Dr. Yoji AkaoDocument6 pagesWhat Is QFD?: Dr. Yoji AkaoANo ratings yet

- KANBANDocument19 pagesKANBANpuneetnmNo ratings yet

- Syllabus Primavera P6Document6 pagesSyllabus Primavera P6Sandeep JoshiNo ratings yet

- Pilot Run Report 0702Document23 pagesPilot Run Report 0702Greg MackeyNo ratings yet

- Production ManagementDocument108 pagesProduction ManagementQuwas Tinnish100% (1)

- Cocu 3 - Slaughtering Hygiene and Sanitation InspectionDocument9 pagesCocu 3 - Slaughtering Hygiene and Sanitation InspectionsyueadashebangNo ratings yet

- Zero Defect and Risk Mitigation With Advanced AnalyticsDocument52 pagesZero Defect and Risk Mitigation With Advanced AnalyticsSelvaraj SNo ratings yet

- Factors, Measures, and Problems of Quality Costs Program Implementation in The Manufacturing EnvironmentDocument6 pagesFactors, Measures, and Problems of Quality Costs Program Implementation in The Manufacturing EnvironmentFahad IzharNo ratings yet

- 10 MovementDocument26 pages10 MovementjvanandhNo ratings yet

- Enterprise Dynamics TutorialDocument66 pagesEnterprise Dynamics TutorialBaracNo ratings yet

- KANBANDocument24 pagesKANBANSalwin Joseph ANo ratings yet

- Material Requirements Planning FinalDocument16 pagesMaterial Requirements Planning Finalniharika95323100% (2)

- Maintenance ManagementDocument40 pagesMaintenance ManagementAmila ThibbotuwawaNo ratings yet

- Operations Management (OPM530) C10 Project ManagementDocument30 pagesOperations Management (OPM530) C10 Project Managementazwan ayopNo ratings yet

- Sustaining The Gains: Transitioning The Black Belt Project: © 2001 Conceptflow 0Document19 pagesSustaining The Gains: Transitioning The Black Belt Project: © 2001 Conceptflow 0anjo0225No ratings yet

- Value Stream Mapping - TQMDocument27 pagesValue Stream Mapping - TQMyashar2500No ratings yet

- Job DescriptionDocument2 pagesJob DescriptionPhan Huỳnh Diễm ThảoNo ratings yet

- Good Manufacturing Practices (GMP) Checklist Name of Winner's Outlet: Month: DateDocument4 pagesGood Manufacturing Practices (GMP) Checklist Name of Winner's Outlet: Month: DateYashini BhuguthNo ratings yet

- Term PaperDocument4 pagesTerm PaperPraneeth Akula SonaNo ratings yet

- Tools of Lean MaufacturingDocument22 pagesTools of Lean Maufacturingsahu_dishaNo ratings yet

- Project Quality Management A Complete Guide - 2019 EditionFrom EverandProject Quality Management A Complete Guide - 2019 EditionNo ratings yet

- KANBAN: Japanese Signaling System for JIT ProductionDocument28 pagesKANBAN: Japanese Signaling System for JIT ProductionSourav SinhaNo ratings yet

- Computer Science Worksheet (Chapter 4, 5) Class I: Q1.Identify The Parts of Computer and Write Their NamesDocument2 pagesComputer Science Worksheet (Chapter 4, 5) Class I: Q1.Identify The Parts of Computer and Write Their NamesRocket FireNo ratings yet

- Dirty Little SecretsDocument8 pagesDirty Little SecretsRudy LederNo ratings yet

- Inpho DTMaster 0915 PDFDocument2 pagesInpho DTMaster 0915 PDFDelasdriana WiharjaNo ratings yet

- Objective TestsDocument2 pagesObjective TestsobepspNo ratings yet

- Mars Inland User's Guide: Booklet 2Document52 pagesMars Inland User's Guide: Booklet 2JESUS SULBARANNo ratings yet

- XPort Pro User GuideDocument151 pagesXPort Pro User Guidemar_barudjNo ratings yet

- CD Lab FileDocument28 pagesCD Lab FileAyush MishraNo ratings yet

- Numerical Solution Using Newton-Raphson MethodDocument10 pagesNumerical Solution Using Newton-Raphson MethodhuynhnhuNo ratings yet

- Multiple SsidDocument4 pagesMultiple SsidPrismaNo ratings yet

- AXIS Audio Manager Pro AXIS Audio Manager C7050 AXIS Audio Manager Pro AXIS Audio Manager Pro C7050 MK IIDocument39 pagesAXIS Audio Manager Pro AXIS Audio Manager C7050 AXIS Audio Manager Pro AXIS Audio Manager Pro C7050 MK IISyed Rahmath AliNo ratings yet

- Chapter 8: Central Processing Unit: Cpe 252: Computer Organization 1Document30 pagesChapter 8: Central Processing Unit: Cpe 252: Computer Organization 1Tanvi SharmaNo ratings yet

- StudentManual Cf238studDocument716 pagesStudentManual Cf238studaliscribd123456No ratings yet

- Nr41 Blaise 41 UKTotalDocument48 pagesNr41 Blaise 41 UKTotalangdrakeNo ratings yet

- HikCentral Web Client ManualDocument961 pagesHikCentral Web Client ManualArmel SimoNo ratings yet

- Kumpulan Kuis KuisDocument24 pagesKumpulan Kuis KuisRani Maharani100% (1)

- Smart Call Home Quick Start Configuration Guide For Cisco Integrated Services RoutersDocument5 pagesSmart Call Home Quick Start Configuration Guide For Cisco Integrated Services RoutersYen Lung LeeNo ratings yet

- Download Byculla To Bangkok EpubDocument3 pagesDownload Byculla To Bangkok EpubSurajit MondalNo ratings yet

- Plan and dispatch efficiently with IVU.railDocument32 pagesPlan and dispatch efficiently with IVU.railmakbadrusNo ratings yet

- Map Info Pro Release NotesDocument29 pagesMap Info Pro Release NotesFANI INDAHSARINo ratings yet

- Alumni Portal Project ReportDocument28 pagesAlumni Portal Project ReportBharat ChaudharyNo ratings yet

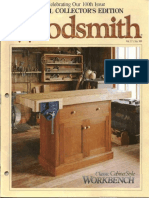

- Woodsmith - 100Document31 pagesWoodsmith - 100rsotoqp100% (2)

- LAN MessengerDocument57 pagesLAN MessengerMudit Dhawan100% (4)

- Improving The Plug-In Interface For CellDesignerDocument4 pagesImproving The Plug-In Interface For CellDesignerYusef VazirabadNo ratings yet

- Digital Data Network DDNDocument28 pagesDigital Data Network DDNchandanNo ratings yet

- Walmart's Keys To Successful Supply Chain ManagementDocument9 pagesWalmart's Keys To Successful Supply Chain ManagementGanesh PajweNo ratings yet

- Win32 API Reference For HLA - GDI32 PDFDocument126 pagesWin32 API Reference For HLA - GDI32 PDFz4rm4rNo ratings yet

- Abhijit Thakur - ResumeDocument4 pagesAbhijit Thakur - ResumeTejas MorajkarNo ratings yet

- Io T2Document6 pagesIo T2Rupesh MaratheNo ratings yet

- How To Use Canva Pro Free: Join Priya's Dogra Telegram ChannelDocument7 pagesHow To Use Canva Pro Free: Join Priya's Dogra Telegram ChannelAnubhav VermaNo ratings yet

- Introduction To Unix File SystemDocument7 pagesIntroduction To Unix File SystemAnand DuraiswamyNo ratings yet