Professional Documents

Culture Documents

Application of RSM in Characterizing Synthetic Oil with Nanoparticles

Uploaded by

Nor Syahirah MohamadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of RSM in Characterizing Synthetic Oil with Nanoparticles

Uploaded by

Nor Syahirah MohamadCopyright:

Available Formats

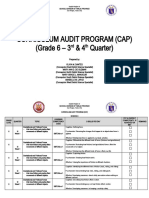

APPLICATION OF RESPONSE SURFACE

METHODOLOGY IN CHARACTERIZATION

OF SYNTHETIC OIL WITH

NANOPARTICLES

Nor Syahirah Mohamad1,2, Salmiah Kasolang1,2

1

Faculty of Mechanical Engineering, Universiti Teknologi MARA,40450 Shah

Alam Selangor , Malaysia

2

Tribology Group, Faculty of Mechanical Engineering, Universiti Teknologi

MARA, 40450 Shah Alam, Selangor Malaysia

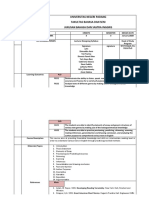

ABSTRACT METHODOLOGY

An optimized section modeled is often deployed to reduce trial and error in

experiment approach. In this study, Box-Behnken design (BBD) approach Sample Pin and disc material

has been used to investigate the characteristic of lubricant. In BBD, this preparation Synthetic oil (SAE 10W40)

approach based on multivariate whereby the effect of different parameters

is considered simultaneously. Hence, it is a non-linear system which is more Design of

realistic of the actual phenomenon. In this study, the effect of three experimen Box-behnken design

independent variables namely speed, load and concentration of TiO2 on the t

coefficient of friction (COF) was investigated. Each independent variable was Tribological

set at three-level: lower, middle and upper limit. By using this approach, the Pin-on-disc machine

test

number of experiment has reduced to 15 experiments from 100

experiments without optimization method. The result obtained from BBD has

Data

shown the most influential parameter which was speed followed by analysis RSM

concentration of TiO2 as the least normal load. Analysis of variance (ANOVA)

indicated that the proposed experiments from quadratic model successfully

interpreted the experimental data with a coefficient of determination of R 2 =

0.9931 and adjusted R2 = 0.9806. From the contour plot of BBD, the DISCUSSION

optimization zone for interacting variables can be determined. The zone

provide the range of values approximately at a load below than 11 kg and Second-order linear

ANOVA analysis

beyond than 17 kg with speed in the range of 1200 rpm to 1900 rpm exhibit equation model

a better reduction of friction.

OBJECTIVES

OBJECTIVE

to investigate the main effect of three independent variables to the

coefficient of friction (COF).

to analyse the ANOVA and RSMSoptimization zone from interacting

variables.

INTRODUCTION

Main Effect Plot

.these inorganic nanoparticles are expected to

Nanoparticles

exhibit lubricating properties as low as 2 wt% RSM analysis

additive

concentration and to be applicable at high and

severe conditions. [1]

nanoparticle

s .nanoparticles dispersed in lubricants are

effective in reducing level of friction and wear [1]

the deposit of nanoparticles act a a third body,

debris reducing asperity interactions and thus increasing

load carrying capacity of the rubbing pairs. [2]

Response

Surface useful method to determine for optimum Optimization of COF

Methodology operating conditions based on several

(RSM) experiments done [3].

simplify and reduce the number of

experiments to be done [4].

analyze the interactions between input

variables that related to output variables

and identify the optimal response within

the experimental region [5].

CONCLUSION

REFERENCES (i) The ANOVA analysis reveals that speed is the main parameter,

which has greater influence than load and concentration. The

interaction of input variables indicates nanoparticles also have a

[1]Y. Hwang, C. Lee, Y. Choi, S. Cheong, D. Kim, K. Lee, J. Lee, and S. H. Kim, Effect of the size and

morphology of particles dispersed in nano-oil on friction performance between rotating discs, J. Mech. significant effect on friction. Although it is not the main effect

Sci. Technol., vol. 25, no. 11, pp. 28532857, Nov. 2011. to friction, it creates a protective film formation in order to

[2] F. Chinas-Castillo and H. A. Spikes, Mechanism of Action of Colloidal Solid Dispersions, J. Tribol., vol.

125, no. 3, p. 552, Jul. 2003.

reduce contact between interfacial surfaces during extreme

[3] R. V Lenth. 2010. Response-surface methods in R using rsm. J. Stat. Softw. 32(7):1 17. speed and load conditions.

[4] D. I. Ahmed, S. Kasolang, B. A. Khidhir, and N. R. Abdullah. 2013. Application of Response Surface (ii) The optimization zone shows approximately at load below than

Methodology to Predict Oil-Film Friction in Journal Bearing. Applied. Mechanical. Material. 393: 931937.

[5] L. Wu, K. L. Yick, S. P. Ng, and J. Yip. 2012. Application of the Box-Behnken design to the optimization 11 kg and beyond than 17 kg with speed in the range of 1200

of process parameters in foam cup molding. Expert Syst. Appl. 39(9):80598065. rpm to 1900 rpm exhibit better reduction of friction.

You might also like

- Experimental Optimization in Polymer BLEND Composite Preparation Based On Mix Level of Taguchi Robust DesignDocument10 pagesExperimental Optimization in Polymer BLEND Composite Preparation Based On Mix Level of Taguchi Robust DesignPuteh SoloNo ratings yet

- 1 s2.0 S0306261921017177 MainDocument13 pages1 s2.0 S0306261921017177 MainDaniel MesaNo ratings yet

- 2015 Rapid Analysis of Diesel Fuel Properties by Near Infrared Reflectance SpectraDocument8 pages2015 Rapid Analysis of Diesel Fuel Properties by Near Infrared Reflectance SpectraPaulo SérgioNo ratings yet

- Vibration of NanolubricantDocument3 pagesVibration of NanolubricantshakinaNo ratings yet

- Dynamics and Identification of A Binary Distillation ColumnDocument11 pagesDynamics and Identification of A Binary Distillation ColumnMMHFNo ratings yet

- Taguchi Method Approach On Effect of Lubrication Condition On Surface Roughness in Milling OperationDocument6 pagesTaguchi Method Approach On Effect of Lubrication Condition On Surface Roughness in Milling OperationBalu BhsNo ratings yet

- Ullah 15 Optimizationofsaponificationin CSTRDocument10 pagesUllah 15 Optimizationofsaponificationin CSTRahmed khaledNo ratings yet

- 16 Xylene Solubles in PolypropyleneDocument2 pages16 Xylene Solubles in PolypropylenegimgimoNo ratings yet

- Hasanina 2017Document10 pagesHasanina 2017Chiew Fei HaNo ratings yet

- Design of Experiments: How To Optimize Products and ProcessesDocument2 pagesDesign of Experiments: How To Optimize Products and Processesos osNo ratings yet

- SCR Reactor Performance Profiling and Results Analysis PDFDocument7 pagesSCR Reactor Performance Profiling and Results Analysis PDFkangsungjinNo ratings yet

- UETLahorejournal IhsanDocument10 pagesUETLahorejournal IhsanArshitNo ratings yet

- Optimization of Saponification Reaction in A Continuous Stirred Tank Reactor (CSTR) Using Design of ExperimentsDocument9 pagesOptimization of Saponification Reaction in A Continuous Stirred Tank Reactor (CSTR) Using Design of ExperimentsAnel MamaniNo ratings yet

- Nanoparticle Enhanced Lubricants Tribological StudyDocument8 pagesNanoparticle Enhanced Lubricants Tribological StudyNor Syahirah MohamadNo ratings yet

- CYDAR new functionalities and modulesDocument2 pagesCYDAR new functionalities and modulesWahid MiaNo ratings yet

- 2014 - Liu - DampersDocument15 pages2014 - Liu - DampersChiara GastaldiNo ratings yet

- Effect of Lean Primaryzone Operation On Emissions and Stability of Non-Premixed CombustorsDocument12 pagesEffect of Lean Primaryzone Operation On Emissions and Stability of Non-Premixed Combustorsmechmuthu1No ratings yet

- UETLahorejournal IhsanDocument10 pagesUETLahorejournal Ihsanahmed khaledNo ratings yet

- Mixing Analysis in A Tank Stirred With Ekato Intermig ImpellersDocument13 pagesMixing Analysis in A Tank Stirred With Ekato Intermig ImpellersBheemannaChandurNo ratings yet

- Effects of Fatty Acids On Low-Sulfur Diesel LubricityDocument8 pagesEffects of Fatty Acids On Low-Sulfur Diesel LubricityAashish GauravNo ratings yet

- Oral Full Paper PDF. 2 PDFDocument500 pagesOral Full Paper PDF. 2 PDFMeera BalachandranNo ratings yet

- Modified Single BaseDocument8 pagesModified Single BasesilvanaNo ratings yet

- Two Dimensional Laminar Fluid Flow in A Square Cavity Using CFDDocument18 pagesTwo Dimensional Laminar Fluid Flow in A Square Cavity Using CFDLala Samprit RayNo ratings yet

- Application of Taguchi Method For Process Enhancement PDFDocument5 pagesApplication of Taguchi Method For Process Enhancement PDFBilal AminNo ratings yet

- Optimization of Membrane Filtration SystemsDocument5 pagesOptimization of Membrane Filtration SystemsHamid DamghaniNo ratings yet

- 1 s2.0 S1385894721053456 MainDocument14 pages1 s2.0 S1385894721053456 Main1093827066cNo ratings yet

- IJCCE Volume 36 Issue 2 Pages 153-174Document22 pagesIJCCE Volume 36 Issue 2 Pages 153-174EYAD BELALIANo ratings yet

- Microchemical Journal: Roman M. Balabin, Ravilya Z. Sa Fieva, Ekaterina I. LomakinaDocument8 pagesMicrochemical Journal: Roman M. Balabin, Ravilya Z. Sa Fieva, Ekaterina I. LomakinaLuqmanNo ratings yet

- Laidi 2020Document14 pagesLaidi 2020Cherif SI MOUSSANo ratings yet

- 5 Fan2007Document10 pages5 Fan2007Wilmer ContrerasNo ratings yet

- 4 Ushie ProofijiscDocument10 pages4 Ushie ProofijiscnickususNo ratings yet

- Influence of Sample Mass on IGC-SEA ResultsDocument5 pagesInfluence of Sample Mass on IGC-SEA ResultsXin辛No ratings yet

- White Paper - Comparison of EN 14078 and ASTM D7371 Infrared Biodiesel MethodsDocument2 pagesWhite Paper - Comparison of EN 14078 and ASTM D7371 Infrared Biodiesel MethodsMary Soledad Huarcaya Espino100% (1)

- Ateshkadi 2000Document8 pagesAteshkadi 2000VaishnaviNo ratings yet

- A Novel Hybrid Particle Swarm Optimizer With Multi Verse OptimizerDocument17 pagesA Novel Hybrid Particle Swarm Optimizer With Multi Verse OptimizerchandrasekarNo ratings yet

- 2.2.58. Inductively Coupled Plasma-Mass SpectrometryDocument2 pages2.2.58. Inductively Coupled Plasma-Mass SpectrometryPablo ParraNo ratings yet

- 234-Article Text-2909-2-10-20120708Document8 pages234-Article Text-2909-2-10-20120708nataliacaveroNo ratings yet

- Artigo 2 - Limits and Possibilities of Refractive Index in Atomic SystemsDocument6 pagesArtigo 2 - Limits and Possibilities of Refractive Index in Atomic SystemsHebert BritoNo ratings yet

- Verification of WWTP Design Guidelines With Activated Sludge Process ModelsDocument10 pagesVerification of WWTP Design Guidelines With Activated Sludge Process ModelsAbass MarrakchiNo ratings yet

- Lode 2003Document14 pagesLode 2003Ionut BanuNo ratings yet

- 1 s2.0 S0022460X2300113X MainDocument18 pages1 s2.0 S0022460X2300113X MainmohamedNo ratings yet

- Matecconf cmss2018 02086Document6 pagesMatecconf cmss2018 02086IvanRomanovićNo ratings yet

- Interlaboratory Comparison of Radiated Emissions in Automotive EMCDocument5 pagesInterlaboratory Comparison of Radiated Emissions in Automotive EMCGundars AsmanisNo ratings yet

- JPST - Volume 2 - Issue 1 - Pages 16-26Document14 pagesJPST - Volume 2 - Issue 1 - Pages 16-26Sahand NekoeianNo ratings yet

- Estimation of Levocetirizine in Bulk and Formulation by First Order Derivative Area Under Curve UV-Spectrophotometric MethodsDocument7 pagesEstimation of Levocetirizine in Bulk and Formulation by First Order Derivative Area Under Curve UV-Spectrophotometric Methodsnhan phamNo ratings yet

- Resonant Gas Sensor and Switch Operating in Air With Metal-Organic Frameworks CoatingDocument8 pagesResonant Gas Sensor and Switch Operating in Air With Metal-Organic Frameworks CoatingSiddhanta RoyNo ratings yet

- Research Article: Porosity Analysis of Plasma Sprayed Coating by Application of Soft ComputingDocument7 pagesResearch Article: Porosity Analysis of Plasma Sprayed Coating by Application of Soft Computingsuresh_501No ratings yet

- Optimize SLM Parameters Using Taguchi MethodDocument7 pagesOptimize SLM Parameters Using Taguchi MethodHa Linh PhanNo ratings yet

- Experimental Investigation and Optimization of Machining Parameters For Surface Roughness in CNC Turning by Taguchi MethodDocument6 pagesExperimental Investigation and Optimization of Machining Parameters For Surface Roughness in CNC Turning by Taguchi MethodEgehan ÜnalNo ratings yet

- Characteristic Concentration vs. Detection Limit in Atomic AbsorptionDocument4 pagesCharacteristic Concentration vs. Detection Limit in Atomic AbsorptionJorge Luis Bautista SantosNo ratings yet

- Optimization of Tribological Performance of hBN/AL O Nanoparticles As Engine Oil AdditivesDocument7 pagesOptimization of Tribological Performance of hBN/AL O Nanoparticles As Engine Oil Additiveskamal touilebNo ratings yet

- Activated Carbon Adsorption of FurfuralDocument8 pagesActivated Carbon Adsorption of FurfuralAmmr MahmoodNo ratings yet

- 1990 - CameronDocument8 pages1990 - CameronChiara GastaldiNo ratings yet

- DeepaPrabhu IJMPERD2020Q3Document15 pagesDeepaPrabhu IJMPERD2020Q3MarcioNo ratings yet

- Engine Emissions Measurement Techniques: Michele NeodoDocument7 pagesEngine Emissions Measurement Techniques: Michele NeodoVishnu RamNo ratings yet

- Enhanced Dispersibility of MoS2 Nanoparticles in Poly-α-Olephines Lubricant Through Surface ModificationDocument6 pagesEnhanced Dispersibility of MoS2 Nanoparticles in Poly-α-Olephines Lubricant Through Surface ModificationZoubir SaidiNo ratings yet

- Sustainability 13 11411 v3 PDFDocument28 pagesSustainability 13 11411 v3 PDFVignesh the sunNo ratings yet

- Do Not Know16Document5 pagesDo Not Know16SaurabhTripathiNo ratings yet

- Compendium of Analytical Nomenclature: Definitive Rules 1977From EverandCompendium of Analytical Nomenclature: Definitive Rules 1977No ratings yet

- Diagram 1 Shows The Vertebrate Animals. Mark (True) The Animals Which Are Cold-Blooded.Document10 pagesDiagram 1 Shows The Vertebrate Animals. Mark (True) The Animals Which Are Cold-Blooded.Nor Syahirah MohamadNo ratings yet

- Chapter 4 Heat Teacher's GuideDocument34 pagesChapter 4 Heat Teacher's GuideAhmad Zaidi100% (9)

- Sabah Trip ItenaryDocument3 pagesSabah Trip ItenaryNor Syahirah MohamadNo ratings yet

- Tribology Characteristic of Journal Bearing Material Under (Repaired)Document8 pagesTribology Characteristic of Journal Bearing Material Under (Repaired)Nor Syahirah MohamadNo ratings yet

- TQM (Finding 2)Document4 pagesTQM (Finding 2)Nor Syahirah MohamadNo ratings yet

- KSSM Tingkatan 2 Bab 1 Biodiversiti (Bi)Document12 pagesKSSM Tingkatan 2 Bab 1 Biodiversiti (Bi)Nor Syahirah MohamadNo ratings yet

- Chapter 5 Light STUDENT'S MODULEDocument38 pagesChapter 5 Light STUDENT'S MODULEMohd Khairul Anuar100% (4)

- Academic Phrasebank Abstract and Introduction SectionsDocument17 pagesAcademic Phrasebank Abstract and Introduction SectionsTrương ThiênNo ratings yet

- Laporan Kemajuan Penyelidikan: Institut Pengajian SiswazahDocument3 pagesLaporan Kemajuan Penyelidikan: Institut Pengajian SiswazahNor Syahirah MohamadNo ratings yet

- List of Figure ILT JournalDocument2 pagesList of Figure ILT JournalNor Syahirah MohamadNo ratings yet

- ILT No Author DetailsDocument6 pagesILT No Author DetailsNor Syahirah MohamadNo ratings yet

- Chemical Substance Quantities SuppliersDocument1 pageChemical Substance Quantities SuppliersNor Syahirah MohamadNo ratings yet

- Jadual Home Tuition 2017Document1 pageJadual Home Tuition 2017Nor Syahirah MohamadNo ratings yet

- TQM (Findings)Document4 pagesTQM (Findings)Nor Syahirah MohamadNo ratings yet

- TQM (Finding 3)Document3 pagesTQM (Finding 3)Nor Syahirah MohamadNo ratings yet

- Gantt ChartDocument3 pagesGantt ChartNor Syahirah MohamadNo ratings yet

- TQM (Findings)Document4 pagesTQM (Findings)Nor Syahirah MohamadNo ratings yet

- Finding Previous PaperDocument12 pagesFinding Previous PaperNor Syahirah MohamadNo ratings yet

- Nanoparticle Enhanced Lubricants Tribological StudyDocument8 pagesNanoparticle Enhanced Lubricants Tribological StudyNor Syahirah MohamadNo ratings yet

- 8am 9am 9.30am 10am 11am 11.30pm 12pm 12.30pm 1pm 2pm 2.30pm 3pm 4pm 4.30pm 5pm 5.30pmDocument6 pages8am 9am 9.30am 10am 11am 11.30pm 12pm 12.30pm 1pm 2pm 2.30pm 3pm 4pm 4.30pm 5pm 5.30pmNor Syahirah MohamadNo ratings yet

- Chemistry Chapter 1 Form 5Document26 pagesChemistry Chapter 1 Form 5didididiidid100% (2)

- Guideline Thesis 2015Document62 pagesGuideline Thesis 2015Nor Syahirah MohamadNo ratings yet

- Nota Ringkas Kimia Form 4 5Document45 pagesNota Ringkas Kimia Form 4 5Nor Syahirah MohamadNo ratings yet

- Research GapDocument4 pagesResearch GapNor Syahirah MohamadNo ratings yet

- Ilt Journal EditedDocument6 pagesIlt Journal EditedNor Syahirah MohamadNo ratings yet

- Mind Map Chapter 2 Chemistry Form 5Document1 pageMind Map Chapter 2 Chemistry Form 5Nor Syahirah MohamadNo ratings yet

- Kertas 1 Pep. Set 10 SPM 2016 - Soalan PDFDocument18 pagesKertas 1 Pep. Set 10 SPM 2016 - Soalan PDFNor Syahirah MohamadNo ratings yet

- 1-Concept of Stress and Strain (Sept 2012)Document37 pages1-Concept of Stress and Strain (Sept 2012)Nor Syahirah MohamadNo ratings yet

- PROPOSALDocument36 pagesPROPOSALNor Syahirah MohamadNo ratings yet

- Additive Evaluation to Enhance Lubricant PerformanceDocument1 pageAdditive Evaluation to Enhance Lubricant PerformanceNor Syahirah MohamadNo ratings yet

- DepEd-Region III Schools Division of Tarlac Province Curriculum Audit Program (CAPDocument20 pagesDepEd-Region III Schools Division of Tarlac Province Curriculum Audit Program (CAPClaudine Manuel LibunaoNo ratings yet

- RPS Intermediate Reading (January 2020)Document12 pagesRPS Intermediate Reading (January 2020)Ahsanuz ZikriNo ratings yet

- Expressing Ideas and OpinionDocument4 pagesExpressing Ideas and OpinionNoman ShahzadNo ratings yet

- Seismic Hazard Modelling For Malaysia 2017Document24 pagesSeismic Hazard Modelling For Malaysia 2017Zeric TengNo ratings yet

- Personality Testing Industry Growth and ControversiesDocument1 pagePersonality Testing Industry Growth and ControversiesAkanshaNo ratings yet

- Dokumen - Tips - Igenetics A Molecular Approach Test Bank 1 Test Bank For Igenetics 30 The CentrosomesDocument27 pagesDokumen - Tips - Igenetics A Molecular Approach Test Bank 1 Test Bank For Igenetics 30 The CentrosomesSamruddhi KarambelkarNo ratings yet

- 27-07-2020 - SR - ICON ALL<-Prog-I&II, All - INDIA - e-TEST - SERIES - Jee-ADV (2018-P1&P2) - AFT-09 - FINAL KEYDocument1 page27-07-2020 - SR - ICON ALL<-Prog-I&II, All - INDIA - e-TEST - SERIES - Jee-ADV (2018-P1&P2) - AFT-09 - FINAL KEYSai GokulNo ratings yet

- Kinetic-And-Potential-Energy-Worksheet-Examples Key PDFDocument2 pagesKinetic-And-Potential-Energy-Worksheet-Examples Key PDFMa Antoinette Mohagan100% (1)

- Hilario-Marvin S - FS1 - E-PortfolioDocument5 pagesHilario-Marvin S - FS1 - E-PortfolioMARVIN HILARIONo ratings yet

- Academic Writing Siap CetakDocument90 pagesAcademic Writing Siap CetakRetno OktavianiNo ratings yet

- UCE Mathematics Paper 1: Solving Problems on Functions, Algebra, Geometry and StatisticsDocument4 pagesUCE Mathematics Paper 1: Solving Problems on Functions, Algebra, Geometry and StatisticsAthiyo MartinNo ratings yet

- By Simply Sims: Addition and SubtractionDocument12 pagesBy Simply Sims: Addition and Subtractionsyanet slkNo ratings yet

- KSCST Project ReportDocument10 pagesKSCST Project ReportGururaj Tavildar100% (3)

- BD Chaurasiya Human Anatomy For Dental StudentsDocument714 pagesBD Chaurasiya Human Anatomy For Dental StudentsBhumika Sharma100% (14)

- Environment: Theme: Reading (B1-C1)Document3 pagesEnvironment: Theme: Reading (B1-C1)Guru MoorthyNo ratings yet

- CBSE Class 7 Geography Chapter 5 Notes - WaterDocument7 pagesCBSE Class 7 Geography Chapter 5 Notes - WaterTottleNo ratings yet

- Soal Bahasa Inggris Part 2Document15 pagesSoal Bahasa Inggris Part 2ieki aiainNo ratings yet

- María Alejandra Alvarez - Pharmacological Properties of Native Plants From Argentina-Springer International Publishing (2019)Document268 pagesMaría Alejandra Alvarez - Pharmacological Properties of Native Plants From Argentina-Springer International Publishing (2019)fesooNo ratings yet

- World History 1: Five Characteristics of CivilizationDocument3 pagesWorld History 1: Five Characteristics of CivilizationHenry BilanNo ratings yet

- SURVEYING - 1 Short Answers IDocument5 pagesSURVEYING - 1 Short Answers IHarish MerugumalaNo ratings yet

- Distillery Safety Audit Report (Is 14489)Document24 pagesDistillery Safety Audit Report (Is 14489)Pankaj Goel100% (2)

- Human PsychologyDocument17 pagesHuman PsychologyJackNo ratings yet

- Sci Worksheet W5 Act 1Document4 pagesSci Worksheet W5 Act 1Mae GuerreroNo ratings yet

- Building Learning Commitment - Perdalin-Project HopeDocument18 pagesBuilding Learning Commitment - Perdalin-Project Hopesusy kusumawardaniNo ratings yet

- Differences Between Solids and FluidsDocument4 pagesDifferences Between Solids and FluidsgknindrasenanNo ratings yet

- The Esoterrorists - Sample Characters PDFDocument9 pagesThe Esoterrorists - Sample Characters PDFbubbaNo ratings yet

- Engineering-Physics-Notes 3 U8 PDFDocument78 pagesEngineering-Physics-Notes 3 U8 PDFKarthik KumarNo ratings yet

- Swarm Optimization (Gso) Dalam PenyelesaianDocument10 pagesSwarm Optimization (Gso) Dalam PenyelesaianfajarandreawanNo ratings yet

- Europass Curriculum Vitae: Updated January 4, 2021Document4 pagesEuropass Curriculum Vitae: Updated January 4, 2021Сарангэрэл БNo ratings yet

- Genetically Modified Organisms and Biosafety PDFDocument47 pagesGenetically Modified Organisms and Biosafety PDFrinda78No ratings yet