Professional Documents

Culture Documents

Radiography

Uploaded by

dombipin0 ratings0% found this document useful (0 votes)

54 views29 pagesRadiography testing methods

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRadiography testing methods

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

54 views29 pagesRadiography

Uploaded by

dombipinRadiography testing methods

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 29

RADIOGRAPHY

What are the types of

radiation emitted by

isotopes?

There are three types of radiation as:

A. Alpha particle - Particle.

B. Beta particles - Particle.

C. Gamma - Ray.

What is the charges on Alpha particle, Beta particles

particle and

Gamma ray & compare their relative penetration?

Charges on radiation are: -

A. Alpha particle particle) : -

Positive charge & less penetrating in comparison to

particle &

Ray. They can be stopped by a thin sheet of paper.

B. Beta particles - particle) : -

Negative charge & have definite range of penetration.

Easily

absorbed in the matter.

C. Gamma ray: -

No charge & highly penetrating.

Gamma ray source

Iridium 192

Iridium 192

Produced byneutronbombardment of Iridium191.The

radioisotope disintegrates toplatinum192

andOsmium192 andgives out beta particle

andmedium energygamma rays.Itsrelatively lower

energy radiation,high specific activityand reasonable

activation time combine to make it an easily shielded

powerful radiation source of small physical size.This

isthemost used radioisotope. It is available

asencapsulatedmetallic pelletsin medium weight,

depleted uraniumshielded,remotelyoperated portable

projectors

Iridium 192

Iridium 192 properties :

Half life : 74 Days.

Energy:206

to612kev.Avgenergy :400kev.

Equivalent to 600 kev X-rays.RHM :

470 mR / hr /Ci at1meter distance.

Suitable for radiographyof6

to75mm Steel.

Iridium 192

Cobalt 60

Produced by neutron bombardment of Nickel plated Cobalt

59pellets.The radioisotope disintegratesto Nickel 60and

emits abet particle and high energygamma

rays.Havealong halflife,and takesalongtimetoactivate

[3years]Because of its higher energy, the isotope is

suitable only for thick sections.However,Itcanbeused

forradiography of Steel,Copper andother mediumweight

metals of thicknessranging from25mmto 200 mm.This

isotope is preferredfor radiographyof steel above50

mmfor shorter exposure time.The contrast of

theradiographic images poor when compared to iridiumand

more difficult tointerpret.High-energy ofradiation

requiresheavy shielding.Cobalt 60 equipments are

veryheavy,costly and less mobile

Cobalt 60

Half life : 5.27 Years.

Energy : 1.17 and 1.33 mev.

Avgenergy : 1200kev.

Equivalent to 2 mev X-rays.

RHM : 1.32R / hr / Ci at 1 meter

distance.

Suitable forradiographyof35 to

200mm Steel or equivalent.

Optimum resultin Steel 60 to

150mm

Thulium 170

Thulium is an expensiverare earthelement.Thulium170is produced

by neutron bombardmentof thulium169.

The radioisotopedecays to ytterbium170by emitting two

betaparticles[ 0.968, 0.884 mev ] and two gamma rays [0.084,

0.052 mev ].

ItIsalowenergy radioisotope,useful forradiography of lower atomic

number or low thicknessmedium atomic numbermaterials.

With small physical source size and a thin specimen the radiographic

image is produced by thegamma and x rays[generated by

theabsorbtion ofhighenergy beta particles ofpeak energy

0.9Mev,in the test specimen] and theradiograph will

begood.Forlarger source size and thicker specimen the low energy

gamma rays are absorbed and the radiograph is produced bythe x

rays only with a resultant lossof image quality.

Result insteel above10mmthicknessispoor.

Containers ofthese sources are verysmall and lightweight.

Thulium 170

Half life : 128.6 days.

Energy: 52,

84kevgammaraysand.91 mev beta

particle.

Equivalent to 150 kev X-rays.

RHM : 3mR / hr/ Ciat 1meter

distance.

Suitable for radiographyof2

to12mm SteeL

Selenium75

Selenium -75 is nowgenerally

acknowledgedthroughout the worldto

provide performance benefits

relativetoIridium-192 in the working range

of 5-30 mmsteel.

Selenium-75 hasa softergamma ray

spectrum than Iridium-192

andithasasignificantlylonger half-life. The

isotopes are produced in ceramic pellets and

suitable lighter weight projectors are

available

Selenium75

Halflife:120days.

Energy : 66 to 401 kev.

RHM : 203 mR / hr / Ci at 1 meter.

Suitable forradiographyof10 to

40mm

Processing steps:

Developing:Exposed films are locked in stainless steel

hangers, and immersed in the developer for 5 minutes at

20C

Immediately after immersion the hangers are tapped to

dislodge air bubbles clinging to the

surfaceofthefilms.The developer is then agitatedly

shaking the hangers for 10seconds in everyminute to

maintain uniformdeveloping action.Continuousagitation

significantly reduces developing time.Developingtime

depends on solution temperature andconcentration and

must becorrectedas required.By temperature control

andreplenishment of thedeveloper,constant developing

time can be maintained.

Stop bath

Stop bath :developer solution is

alkaline where as fixer is acidic.

Hence developed films are washed in

2% acetic acid solution or water to

remove traces of developer

remaining on the films before they

are immersed in the fixer solution.

Fixing

Fixing:The films are immersed in the

fixer solution to make the developed

image stable by removing unexposed

silver halide grains by

fixingaction.Recommended

fixingtime is twicetheclearing time

and films can be left in the fixerfor

up to 15minutes

Washing

Washing :following fixing, the films

are washed in running water

for15minutes to remove all

tracesoffixerfrom thesurface.

Washing time canbereduced

byusing suitable

chemicals.Improperlywashed films

become brown with age

Removing watermarks

Removing watermarks:Water

droplets remaining on the surface of

the films afterwashing canbe

removed by dipping the films in a

wetting agent solution before drying.

Drying :Films are finally dried

uniformly by evaporation or by

circulating hot air in a temperature

controlled drying cabinet.

What are the ingredients of

Developer?

Developing Agent: - Metal,

Hydroquinone and Pencil one.

Accelerator: - Sodium carbonate.

Restrainer: - Potassium Bromated.

Preservative: - Sodium Sulphate.

How the Radiographic films are

classified Film types ?

The Radiographic films are classified as: -

Class I : - Highest contrast, Lowest

speed.

Class II : - High contrast, Low speed.

Class III : - Medium contrast, Medium

speed.

Class IV : - Low contrast, High speed.

What is the basis of classification of

radiographic film?

Classification of Radiographic film is

done on the basis of grain size of

Silver Bromide (Silver Bromide

Crystals).

Finer the grain size of Silver Bromide

in emulsion, slower will be the speed.

Generally used crystal size is 0.22,

0.52, 0.68, 0.80 and 1 micron.

radiographic film

D2 / R2 :Low speed, high contrast, extremely fine grain for excellent

image sharpness,can be used with or without lead screen. Suitable for

thin-wall steel, lower densitymaterials, plastics, composites etc.

D4 / R4 :Mediumspeed, high contrast, extremely fine grain for good

image quality, can be used with or withoutleadscreen.Suitablefor

thin-wallsteel

,D5 / R5 :Standard speed, highcontrast, veryfine grain for good image

quality, can be used with or withoutlead screen.Forthin /

mediumthicksteel.

D7 / R7 :Higher speed, high contrast, fine grain, can beused with or

without lead screen. Suitable for thicker parts with gamma and thinner

with x -rays. This isthe most used film for commonapplications.

D8 / R8 :Veryhigh speed, high contrast,medium grain, can be used

with or without lead screen. Suitable for thick steel, castparts

withnon uniform thickness etc.

D10 / R10 :Veryhigh speed,medium contrast, mediumgrain,can be

used with or without lead screen. Suitable for thick steel, parts with

non uniform thickness

Imagequalityindicators[IQI]

Commonly used IQI are: -

A. Wire type Pentameter.

B. Plate type Pentameter.

C. Step type Pentameter.

D. Step- Hole type

Pentameter

CD-7-RT-R write V1.1.exe

IQI

Pentameter should be made of same material as that

of the specimen.

The selection of IQI should be made as: -

For carbon Steel & Low Alloy Steel : -Carbon Steel IQI.

For High Alloy Steel & Stainless Steel: -Stainless Steel

IQI.

For Aluminum & Aluminum Alloy: -Aluminum IQI.

Copper & copper Alloy: - Copper IQI.

Name some IQI?

Wire types IQI : - 1-ISO-7, 6-ISO-12,10-ISO-16

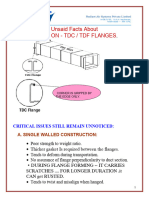

Different types of Radiography

techniques are:

A. Single wall single image

(Panoramic Exposure).

B. Double wall single image.

C. Double wall double image

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Leslie Marie Red - Bs Che3A - Che 126 Pe 1: 1 1 A A B BDocument16 pagesLeslie Marie Red - Bs Che3A - Che 126 Pe 1: 1 1 A A B BJohn Patrick Sanay NunezNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Atwoods Machine ExperimentDocument3 pagesAtwoods Machine ExperimentYmmijNo ratings yet

- Is 101 3 5 1987Document6 pagesIs 101 3 5 1987dombipinNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationSantosh KumarNo ratings yet

- Is 101 6 5 1997 PDFDocument23 pagesIs 101 6 5 1997 PDFdombipinNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Is 101 6 2 1989Document7 pagesIs 101 6 2 1989dombipinNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Is 101 8 2 1990 PDFDocument13 pagesIs 101 8 2 1990 PDFdombipinNo ratings yet

- Is 101 8 2 1990 PDFDocument13 pagesIs 101 8 2 1990 PDFdombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- Abolin Co Guide Metal Surface PreparationDocument26 pagesAbolin Co Guide Metal Surface Preparationvalerica_lupu253No ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationSantosh KumarNo ratings yet

- Is 101 5 3 1999 PDFDocument12 pagesIs 101 5 3 1999 PDFdombipinNo ratings yet

- इंटरनेट मानक का प्रिंट-फ्री परीक्षणDocument5 pagesइंटरनेट मानक का प्रिंट-फ्री परीक्षणdombipinNo ratings yet

- Is 101 5 2 1988 PDFDocument23 pagesIs 101 5 2 1988 PDFdombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument5 pagesDisclosure To Promote The Right To InformationSantosh KumarNo ratings yet

- Is 101 5 1 1988Document9 pagesIs 101 5 1 1988dombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Is 101 4 1 1988 PDFDocument10 pagesIs 101 4 1 1988 PDFdombipinNo ratings yet

- इंटरनेट मानक का फ्लैश प्वाइंटDocument6 pagesइंटरनेट मानक का फ्लैश प्वाइंटdombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- Is 101 2 1 1988 PDFDocument6 pagesIs 101 2 1 1988 PDFdombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- Is.101.3.1.1986 - Paint Test PDFDocument7 pagesIs.101.3.1.1986 - Paint Test PDFdombipinNo ratings yet

- Disclosure To Promote The Right To InformationDocument6 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- Disclosure To Promote The Right To InformationDocument8 pagesDisclosure To Promote The Right To InformationdombipinNo ratings yet

- Chemistry Project on Cosmetic ChemistryDocument48 pagesChemistry Project on Cosmetic ChemistryShubham SehgalNo ratings yet

- Enzyme Controlled Reaction LabDocument2 pagesEnzyme Controlled Reaction Labapi-291218692No ratings yet

- Unsung Science of TDF FlangeDocument3 pagesUnsung Science of TDF FlangeSandeep GalhotraNo ratings yet

- Ammonia ConversionDocument24 pagesAmmonia ConversionKashan AslamNo ratings yet

- Karnataka Common Entrance Test: Question With Solutions of Chemistry, Physics, Mathematics and BiologyDocument55 pagesKarnataka Common Entrance Test: Question With Solutions of Chemistry, Physics, Mathematics and BiologyVikashNo ratings yet

- Edexcel AS Physics Experiment Questions Unit 1Document7 pagesEdexcel AS Physics Experiment Questions Unit 1RaShid KhAnNo ratings yet

- Physics homework solutions for chapter 23 problemsDocument12 pagesPhysics homework solutions for chapter 23 problemsSandeep BadigantiNo ratings yet

- Science ParadoxDocument6 pagesScience ParadoxMahendra JayanNo ratings yet

- Outlines of Organic ChemistryDocument14 pagesOutlines of Organic Chemistrycoolnsmarttt100% (3)

- Unit - 3 - Question BankDocument3 pagesUnit - 3 - Question BankdhavalNo ratings yet

- In-Situ Spectroscopic Studies of Adsorption at The Electrode and ElectrocatalysisDocument10 pagesIn-Situ Spectroscopic Studies of Adsorption at The Electrode and ElectrocatalysisEudes SantosNo ratings yet

- 2014-15 - I B.Tech I SemDocument193 pages2014-15 - I B.Tech I SemKrishna MurthyNo ratings yet

- Inorganic_Chemistry # BrahmastraDocument73 pagesInorganic_Chemistry # BrahmastraNooman ShaikhNo ratings yet

- Tabelul Periodic - Google SearchDocument1 pageTabelul Periodic - Google SearchMariaNo ratings yet

- Fire Theory & Investigation ElementsDocument15 pagesFire Theory & Investigation ElementsAccu Xii VhenzNo ratings yet

- Chapter 24 Molecular Absorption Spectrometry Molecular Spectrometry Uv / Vis / Ir Widely Used Identification Inorganic Organic Biochemical SpeciesDocument42 pagesChapter 24 Molecular Absorption Spectrometry Molecular Spectrometry Uv / Vis / Ir Widely Used Identification Inorganic Organic Biochemical Species陳奕廷go.thuNo ratings yet

- BIOCHEMISTRY CARBOHYDRATESDocument100 pagesBIOCHEMISTRY CARBOHYDRATESJiezl Abellano AfinidadNo ratings yet

- 2016 2017 6 7 Notes QuantumDocument85 pages2016 2017 6 7 Notes QuantumAlexander AdrogueNo ratings yet

- PT Wilmar Biodiesel MSDSDocument5 pagesPT Wilmar Biodiesel MSDSSuweleh MahdiNo ratings yet

- Syloid 244 FP UsaDocument2 pagesSyloid 244 FP UsaCarolline GregorioNo ratings yet

- Chemical Process Control Stephanopoulos PDFDocument376 pagesChemical Process Control Stephanopoulos PDFWahid NoorNo ratings yet

- PT Chapter 1Document13 pagesPT Chapter 1shubhamNo ratings yet

- Ionic ManualDocument44 pagesIonic ManualSelvakumar NatarajanNo ratings yet

- 2010 Catalogueen LbiDocument48 pages2010 Catalogueen LbipashaulNo ratings yet

- 11 Physics Practice PaperDocument10 pages11 Physics Practice PaperIshan AhujaNo ratings yet

- OME754 INDUSTRIALSAFETY-Unit II NotesDocument106 pagesOME754 INDUSTRIALSAFETY-Unit II Notesraghul balaNo ratings yet

- Gas Separator Sizing SpreadsheetDocument19 pagesGas Separator Sizing SpreadsheetSaid FerdjallahNo ratings yet

- 3-4 Gas Laws Int - Reader - Study - Guide PDFDocument6 pages3-4 Gas Laws Int - Reader - Study - Guide PDFVara BikkinaNo ratings yet