Professional Documents

Culture Documents

SSCM CH 2

Uploaded by

Muhammad Ali Tahir0 ratings0% found this document useful (0 votes)

100 views15 pagessscm

Original Title

SSCM ch 2

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsscm

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

100 views15 pagesSSCM CH 2

Uploaded by

Muhammad Ali Tahirsscm

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 15

Supply Chain Management

(3rd Edition)

Chapter 17

Global Supply Chain Management

2007 Pearson Education 16-1

Global Supply Chain

Covers both logistics and operations

Includes activities such as sourcing,

procurement, order processing,

manufacturing, warehousing, inventory

control, servicing and warranty, customs

clearing, wholesaling and distribution

2007 Pearson Education

Two main aspects of GSCM

1. Supply chain as a cross-functional entity

2. Supply chain as the integrator and

coordinator of production and logistics

activities

2007 Pearson Education

Apples Suppliers around the

World

2007 Pearson Education 16-4

2007 Pearson Education 16-5

2007 Pearson Education

World Commodities Map

2007 Pearson Education 16-7

Global Apparel Value Chain

Tracing back the dress you are wearing

2007 Pearson Education

Transactional Complexity

National Semiconductors:

Production:

Produces chips in six different locations: four in the US, one

in Britain and one in Israel

Chips are shipped to seven assembly locations in Southeast

Asia.

Distribution

The final product is shipped to hundreds of facilities all

over the world

20,000 different routes

12 different airlines are involved

95% of the products are delivered within 45 days

5% are delivered within 90 days.

2007 Pearson Education

Complexity: The Magnitude

(Logistics)

The grocery industry could save $30 billion (10% of

operating cost) by using effective logistics strategies

Compaq computers loss of $500 million to $1 billion

in sales in one year

Laptops and desktops were not available when and where customers

were ready to buy them

Boeings forced announcement of write-downs of $2.6b

Raw material shortages, internal and supplier parts shortages.

2007 Pearson Education

Areas to be considered while moving from

domestic to International supply chain

1. Substantial geographical distances

2. Forecasting problems/difficulties in foreign markets

3. Fluctuations in exchange rates for different currencies

4. Demand for great variety of products

5. Inadequate infrastructures such as

labor skills,

availability of supply

Supplier quality

Lack of local process equipments and technologies

Inadequate transportation facilities and

Inadequate telecommunication facilities

2007 Pearson Education

Uncertainty and Risk Factors

August 2005 Hurricane Katrina

P&G coffee supplies from sites around New

Orleans

Six month impact

2002 West Coast port strike

Losses of $1B/day

Store stock-outs, factory shutdowns

1999 Taiwan earthquake

Supply interruptions of HP, Dell

2001 India (Gujarat state) earthquake

Supply interruptions for apparel

manufacturers

2007 Pearson Education

Magnitude of Supply Chain Costs

Cost Elements of a Typical Trade Book

2007 Pearson Education

Magnitude of Supply Chain Costs

Example: The Apparel Industry

Cost per Percent

Shirt Saving

Manufacturer Distributor Retailer Customer $52.72 0%

Manufacturer Distributor Retailer Customer $41.34 28%

Manufacturer Distributor Retailer Customer $20.45 62%

2007 Pearson Education

Global Supply Chain: The Potential

P&Gs estimated savings to retail customers of $65 million through logistics

gains

Dell Computers outperforming of the competition in terms of shareholder

value growth over more than two decades by over 3,000% using:

Direct business model

Build-to-order strategy

Wal-Mart transformation into the worlds largest retailer by changing its

logistics system:

highest sales per square foot, inventory turnover and operating profit of

any discount retailer

2007 Pearson Education

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Indian Oil Corporation Limited: Supplier RecipientDocument1 pageIndian Oil Corporation Limited: Supplier RecipientparamguruNo ratings yet

- Working CapitalDocument10 pagesWorking CapitalSaurabh BhardwajNo ratings yet

- Project Management Approaches at TechlogixDocument6 pagesProject Management Approaches at TechlogixMuhammad Ali TahirNo ratings yet

- VSBDC Financial Statement Resource GuideDocument47 pagesVSBDC Financial Statement Resource GuideMrinal KakkarNo ratings yet

- Our Business Strategy, Leaving A Positive Imprint On Society and The Environment."Document13 pagesOur Business Strategy, Leaving A Positive Imprint On Society and The Environment."Muhammad Ali TahirNo ratings yet

- Strategy ImplementationDocument12 pagesStrategy ImplementationMuhammad Ali TahirNo ratings yet

- Nestle JuicesDocument2 pagesNestle JuicesMuhammad Ali TahirNo ratings yet

- Quiz 4Document1 pageQuiz 4Muhammad Ali TahirNo ratings yet

- Article NoDocument2 pagesArticle NoMuhammad Ali TahirNo ratings yet

- An Overview of Electricity Sector in Pakistan: Executive SummeryDocument23 pagesAn Overview of Electricity Sector in Pakistan: Executive SummeryMuhammad Ali TahirNo ratings yet

- Ravindran, A. Ravi Ufuk Bilsel, R. Wadhwa, Vijay Yang, TaoDocument7 pagesRavindran, A. Ravi Ufuk Bilsel, R. Wadhwa, Vijay Yang, TaoMuhammad Ali TahirNo ratings yet

- Investment Analysis & Portfolio Management: WEEK (21 February To 28th February)Document6 pagesInvestment Analysis & Portfolio Management: WEEK (21 February To 28th February)Muhammad Ali TahirNo ratings yet

- SCM Assignment EditedDocument12 pagesSCM Assignment EditedMuhammad Ali TahirNo ratings yet

- SNGPLDocument20 pagesSNGPLMuhammad Ali TahirNo ratings yet

- Week 6Document5 pagesWeek 6Muhammad Ali TahirNo ratings yet

- Investment Analysis & Portfolio Management: WEEK (21 February To 28th February)Document6 pagesInvestment Analysis & Portfolio Management: WEEK (21 February To 28th February)Muhammad Ali TahirNo ratings yet

- Tensor Catalogue USA PDFDocument72 pagesTensor Catalogue USA PDFdavev2005No ratings yet

- Paper Express SalesDocument1 pagePaper Express Salesapi-6506215No ratings yet

- SCM Presentation - Improving Warehouse Operations DigitallyDocument17 pagesSCM Presentation - Improving Warehouse Operations DigitallyvaisakhgokulNo ratings yet

- NIL Case Outline DigestDocument44 pagesNIL Case Outline DigestCid Benedict PabalanNo ratings yet

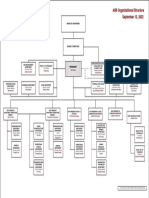

- AIIB Organizational StructureDocument1 pageAIIB Organizational StructureHenintsoa RaNo ratings yet

- Multifamily EbookDocument15 pagesMultifamily EbookLloydMandrellNo ratings yet

- H2 EconomicsDocument6 pagesH2 EconomicsDeclan Raj0% (1)

- Chapter 5 Questions V1Document6 pagesChapter 5 Questions V1prashantgargindia_930% (1)

- Frequently Asked Questions Transition From UL 508C To UL 61800-5-1Document6 pagesFrequently Asked Questions Transition From UL 508C To UL 61800-5-1nomeacueroNo ratings yet

- Salim Ivomas Pratama TBK Bilingual 30 June 2019 Final Director StatementDocument124 pagesSalim Ivomas Pratama TBK Bilingual 30 June 2019 Final Director Statementilham pakpahanNo ratings yet

- DRT Rules. Forms - 2015Document30 pagesDRT Rules. Forms - 2015Sumit SrivastavaNo ratings yet

- Greek Labour LawDocument3 pagesGreek Labour LawSerban MihaelaNo ratings yet

- Matrix Electronics Business Solutions ReportDocument15 pagesMatrix Electronics Business Solutions ReportkisxenaNo ratings yet

- FM11 CH 10 Capital BudgetingDocument56 pagesFM11 CH 10 Capital Budgetingm.idrisNo ratings yet

- Final Internship ReportDocument58 pagesFinal Internship ReportKrishna SahuNo ratings yet

- Recommended Reading List For Operation ManagementDocument1 pageRecommended Reading List For Operation ManagementHakanNo ratings yet

- Adv1 16-4Document1 pageAdv1 16-4M_Sarudi_Putra_4335No ratings yet

- Motores PDFDocument196 pagesMotores PDFDanilo CherresNo ratings yet

- Auditing bank reconciliation proceduresDocument2 pagesAuditing bank reconciliation procedureshsjhsNo ratings yet

- Journal 1: The Role of Digital and Social Media Marketing in Consumer Behaviour I. Executive SummaryDocument10 pagesJournal 1: The Role of Digital and Social Media Marketing in Consumer Behaviour I. Executive SummaryN.SNo ratings yet

- Adrian MittermayrDocument2 pagesAdrian Mittermayrapi-258981850No ratings yet

- Small Industries Development Bank of India (Sidbi) : Growth, Development and Role in The Promotion of Entrepreneurship in Uttar Pradesh (U.P.)Document46 pagesSmall Industries Development Bank of India (Sidbi) : Growth, Development and Role in The Promotion of Entrepreneurship in Uttar Pradesh (U.P.)Suhani jainNo ratings yet

- Water Crisis Collection: Payment1 Payment2 Payment3Document8 pagesWater Crisis Collection: Payment1 Payment2 Payment3Raghotham AcharyaNo ratings yet

- Chapter 8 - Direct Investment and Collaborative StrategiesDocument34 pagesChapter 8 - Direct Investment and Collaborative StrategiesGia GavicaNo ratings yet

- SOP Template Food and Drink Service OBT 08LTB OSP T1FDS 11 12 3Document15 pagesSOP Template Food and Drink Service OBT 08LTB OSP T1FDS 11 12 3Jean Marie Vallee100% (1)

- MCQDocument19 pagesMCQk_Dashy846580% (5)

- Operation and Product Management: LT Col Tauhidul IslamDocument23 pagesOperation and Product Management: LT Col Tauhidul IslamOptimistic EyeNo ratings yet

- CDM Regulations EbookDocument14 pagesCDM Regulations EbookZeeshan BajwaNo ratings yet