Professional Documents

Culture Documents

Vapor Absorption Refrigeration Cycle

Uploaded by

USHA PAWAR0 ratings0% found this document useful (0 votes)

319 views11 pagesVapor Absorption Refrigeration Cycle in ppt format. this has images too. made easy to understand

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVapor Absorption Refrigeration Cycle in ppt format. this has images too. made easy to understand

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

319 views11 pagesVapor Absorption Refrigeration Cycle

Uploaded by

USHA PAWARVapor Absorption Refrigeration Cycle in ppt format. this has images too. made easy to understand

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 11

Vapor Absorption Refrigeration Cycle

Vapor Absorption Refrigeration Cycle

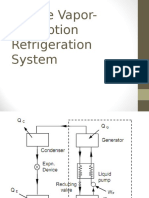

The absorption refrigeration system is a heat

operated unit which uses a refrigerant that is

alternately absorbed and liberated from the

absorbent. In the basic absorption system, the

compressor in the vapor compression cycle is replaced

by an absorber-generator assembly involving less

mechanical work. Figure gives the basic absorption

refrigeration cycle, in which ammonia is the

refrigerant & water is the absorbent. This is known as

the aqua-ammonia absorption system. Ammonia

vapor is vigorously absorbed in water. So when low-

pressure ammonia vapor from the evaporator comes

in contact in the absorber with the weak solution (in

which the concentration of ammonia in water is low)

coming from the generator, it is readily absorbed,

releasing the latent heat of condensation.

The temperature of the solution tends to rise,

while the absorber is cooled by the circulating water,

absorbing the heat of solution (QA), and maintaining a

constant temperature. Strong solution, rich in

ammonia, is pumped to the generator where heat (QG)

is supplied from an external source (steam, electricity,

gas flame, etc.). Since the boiling point of ammonia is

less than that of water, the ammonia vapor is given off

from the aqua-ammonia solution at high pressure, and

the weak solution returns to the absorber through a

pressure reducing valve. The heat exchanger preheats

the strong solution and precools the weak solution,

reducing both the heat to be supplied in the generator

(QG) and the heat to be removed in the absorber (QA).

The ammonia vapor then condenses in the condenser,

is throttled by the expansion valve, and then

evaporates, absorbing the heat of evaporation from

In driving the ammonia vapor out of the solution

in the generator, it is impossible to avoid evaporating

some of the water. This water vapor going in to the

condenser along with the ammonia vapor, after

condensation, may get frozen to ice and block the

expansion valve. So an analyzer-rectifier combination

is used to eliminate water vapor from the ammonia

vapor going into the condenser.

Actual Vapor Absorption Refrigeration Plant wit

h Analyzer & Rectifier

The analyzer is a direct-contact heat exchanger

consisting of a series of trays mounted above the

generator. The strong solution from the absorber flows

downward over the trays to cool the outgoing vapors.

Since the saturation temperature of water is higher

than that of ammonia at a given pressure, it is the

water vapor which condenses first. As the vapor

passes upward through the analyzer. It is cooled and

enriched by ammonia, and the liquid is heated. Thus

the vapor going to the condenser is lower in

temperature and richer in ammonia and the heat input

to the generator is decreased.

The final reduction in the percentage of water

vapor in the ammonia going to the condenser occurs

in the rectifier which is a water-cooled heat exchanger

which condenses water vapor and returns it to the

generator through the drip line, as shown in figure.

The use of a suction line heat exchanger is to reduce

QA and increase QE thus achieving a double benefit. In

the absorber the weak solution is sprayed to expose a

larger surface area so as to accelerate the rate

absorption of ammonia vapor.

Lithium Bromide-Water Absorption Refrigeratio

n Plant

There is another absorption refrigeration

system, namely, lithium bromide- water vapor

absorption. Here the refrigerant is water and the

absorbent in the solution of lithium bromide salt in

water. Since water cannot be cooled below 0C, it can

be used as a refrigerant in air conditioning units.

Lithium bromide solution has a strong affinity for

water vapor because of its very low vapor pressure. It

absorbs water vapor as fast as it is released in the

evaporator.

While the vapor compression refrigeration system

requires the expenditure of high-grade energy in the

form of shaft work to drive the compressor with the

simultaneous disadvantage of vibration and noise, the

absorption refrigeration system requires only low-

grade energy in the form of heat to drive it, and it is

relatively silent in operation and subject to little wear.

Although the COP = QE/QG is low, the absorption units

are usually built when waste heat is available, & they

are built in relatively bigger sizes. One current

application of the absorption system that may grow in

importance is the utilization of solar energy for the

generator heat source of a refrigerator for food

preservation and perhaps for comfort cooling.

You might also like

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963From EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963No ratings yet

- Vapor Absorption SystemsDocument17 pagesVapor Absorption SystemsTalibHussainNo ratings yet

- Vapour AbsorptionDocument10 pagesVapour Absorptiongayakwad12_ramNo ratings yet

- Vapour Absorption RefrigerationDocument29 pagesVapour Absorption RefrigerationmuthuNo ratings yet

- Vapour AbsorptionDocument15 pagesVapour AbsorptionSatheesh ChandranNo ratings yet

- Refrigeration Cycles Study Guide in Powerpoint: To AccompanyDocument20 pagesRefrigeration Cycles Study Guide in Powerpoint: To AccompanyDocumentos De Interés para IngenieríaNo ratings yet

- Vapor-Compression Refrigeration SystemsDocument28 pagesVapor-Compression Refrigeration Systemsm_alodat6144No ratings yet

- Refrigeration SystemDocument37 pagesRefrigeration Systemdeepakdshenoy100% (1)

- Refrigeration Cycles Real Vapor Compression CycleDocument9 pagesRefrigeration Cycles Real Vapor Compression CyclePaul RodgersNo ratings yet

- Refrigeration CycleDocument85 pagesRefrigeration CycleNeha MiracleNo ratings yet

- Chapter 11 PDFDocument8 pagesChapter 11 PDFVisakan ParameswaranNo ratings yet

- P2Document158 pagesP2John MackenzieNo ratings yet

- ADV Refrigeration System Using FlashchamberDocument40 pagesADV Refrigeration System Using FlashchamberAwesm RishuNo ratings yet

- SBS5311 1718 07-Refrigeration PDFDocument66 pagesSBS5311 1718 07-Refrigeration PDFRatnin PanityingNo ratings yet

- Balance Point of Compressor and Capillary TubeDocument13 pagesBalance Point of Compressor and Capillary TubeMonojit KonarNo ratings yet

- Refrigeration System NptelDocument14 pagesRefrigeration System NptelKapil Goyal100% (1)

- A 2-Stage Cascade Refrigeration CycleDocument8 pagesA 2-Stage Cascade Refrigeration CycleSaeikh Z. HassanNo ratings yet

- Refrigeration CyclesDocument29 pagesRefrigeration CyclesJoulie Jonsi100% (1)

- Test On Vapor Compression Refrigeration FINALDocument8 pagesTest On Vapor Compression Refrigeration FINALUdara ManawaduNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- Vapor-Compression Refrigeration CycleDocument23 pagesVapor-Compression Refrigeration CycleJamshidNo ratings yet

- Refrigeration Laboratory Manual 2011Document19 pagesRefrigeration Laboratory Manual 2011Himanshu Uniyal0% (1)

- Vapour Compression RefrigerationDocument38 pagesVapour Compression RefrigerationArvind75% (4)

- Chapter 11 - Refrigeration CyclesDocument25 pagesChapter 11 - Refrigeration CyclesPaul RodgersNo ratings yet

- Refrigeration Cycles: Wan Rosli Wan SulaimanDocument21 pagesRefrigeration Cycles: Wan Rosli Wan Sulaimanعبدالله عمرNo ratings yet

- Innovative Vapor CompressionDocument13 pagesInnovative Vapor CompressionCj MoLanoNo ratings yet

- SBS5311 1718 07-RefrigerationDocument66 pagesSBS5311 1718 07-RefrigerationSam C M Hui100% (1)

- Chiller ConfigurationDocument8 pagesChiller Configurationavid_ankurNo ratings yet

- Multi Pressure Vapour Compression Refrigeration SystemDocument11 pagesMulti Pressure Vapour Compression Refrigeration SystemDeepakNo ratings yet

- Experiment 2Document19 pagesExperiment 2Dilshad S FaisalNo ratings yet

- Presentation Desiccant Cooling SystemDocument17 pagesPresentation Desiccant Cooling Systemarif100% (1)

- Split Type of Air ConditionerDocument8 pagesSplit Type of Air ConditionersadNo ratings yet

- CondenserDocument12 pagesCondenserPrabir Kumar Pati100% (1)

- Refrigeration CycleDocument12 pagesRefrigeration CycleNabankur RayNo ratings yet

- RAC Experiments FinalDocument31 pagesRAC Experiments FinalEr Nikhil KakadeNo ratings yet

- ERT 313 Bioseparation Engineering Gas Absorption: Prepared By: Pn. Hairul Nazirah Abdul HalimDocument57 pagesERT 313 Bioseparation Engineering Gas Absorption: Prepared By: Pn. Hairul Nazirah Abdul HalimVenkateswara RamakrishnanNo ratings yet

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDocument14 pagesLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezNo ratings yet

- Design of Cooling TowerDocument4 pagesDesign of Cooling TowerHadis ShojaeiNo ratings yet

- Vapour Compression Refrigeration Test RigDocument1 pageVapour Compression Refrigeration Test RigPawan NkNo ratings yet

- Types of Air Conditioning SystemsDocument19 pagesTypes of Air Conditioning Systemsa_mohid17No ratings yet

- Effect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabDocument15 pagesEffect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabDilshad S FaisalNo ratings yet

- Carnot Refrigeration CycleDocument11 pagesCarnot Refrigeration CycleZaimNo ratings yet

- Thermo Heat PumpDocument15 pagesThermo Heat PumpAkshay BhadangeNo ratings yet

- Cooling TowerDocument24 pagesCooling TowerMakhdoom Ibad HashmiNo ratings yet

- Refrigeration FundamentalsDocument92 pagesRefrigeration FundamentalsThomas Westgate100% (1)

- Ag 31-011 1215daDocument78 pagesAg 31-011 1215daSicologo CimeNo ratings yet

- Basic Design Vapor-Compression Refrigeration SystemDocument20 pagesBasic Design Vapor-Compression Refrigeration Systemscarmathor90No ratings yet

- Performance and Efficiency Test of Refrigeration Sysytem: (Mel Lab 3 Report)Document14 pagesPerformance and Efficiency Test of Refrigeration Sysytem: (Mel Lab 3 Report)Yhan SombilonNo ratings yet

- 2 To Study VASDocument5 pages2 To Study VASAnand GujaratiNo ratings yet

- VarsDocument25 pagesVarsRuturaj UmaranikarNo ratings yet

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- Vapour Absorption Refrigeration SystemDocument12 pagesVapour Absorption Refrigeration SystemHarshNo ratings yet

- RACDocument3 pagesRACneerajbhayal3456No ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- Simple Vapor-Absorption Refrigeration SystemDocument49 pagesSimple Vapor-Absorption Refrigeration SystemnaccfrancNo ratings yet

- Rac, Module 3-NoteDocument81 pagesRac, Module 3-NoteShan Mathews VettikuzhiyilNo ratings yet

- Vapour Absorption Systen For StudentsDocument49 pagesVapour Absorption Systen For StudentsbernabasNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- What Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour AbsorDocument1 pageWhat Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour Absordhoom 760No ratings yet

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- Chapter 3 Temperature and Its Change (Meeting 3 & 4)Document5 pagesChapter 3 Temperature and Its Change (Meeting 3 & 4)Clara BangunNo ratings yet

- Theory of Chemical Kinetics and Charge Transfer Based On Nonequilibrium ThermodynamicsDocument17 pagesTheory of Chemical Kinetics and Charge Transfer Based On Nonequilibrium ThermodynamicsYoana Yoa YoaNo ratings yet

- Customer Story Kemira Sweden PP62350EN 2Document2 pagesCustomer Story Kemira Sweden PP62350EN 2mohsen123No ratings yet

- Daily Practice Problem (DPP) by J S GILL 26-June-2020Document2 pagesDaily Practice Problem (DPP) by J S GILL 26-June-2020sai thesisNo ratings yet

- WEEK 9 - Chemical Reaction Equilibria Part 1Document34 pagesWEEK 9 - Chemical Reaction Equilibria Part 1Wan Nadatul NadwaNo ratings yet

- More ExercisesDocument3 pagesMore ExercisesAnas Shatnawi100% (1)

- Pi Ti Vi p1 T1 V: Solution To Applied Lecture 1 Fundamentals of Thermal and Hydraulic Machines and Fluid PowerDocument10 pagesPi Ti Vi p1 T1 V: Solution To Applied Lecture 1 Fundamentals of Thermal and Hydraulic Machines and Fluid PoweryanpainNo ratings yet

- Science 9 - Q4 - Week 5Document17 pagesScience 9 - Q4 - Week 5Rhyan Zero-four BaluyutNo ratings yet

- Gas-Vapor Mixtures: Diah Susanti, PH.DDocument26 pagesGas-Vapor Mixtures: Diah Susanti, PH.DDiana KamaliyahNo ratings yet

- Tables of R 134a From NistDocument6 pagesTables of R 134a From NistMarel8980% (1)

- Mazda Technical Service Training Air Conditioning FundamentalsDocument9 pagesMazda Technical Service Training Air Conditioning Fundamentalsmary100% (47)

- Engineering ThermodynamicsDocument1 pageEngineering ThermodynamicsAkshay PatoleNo ratings yet

- Metallurgical Thermo DynamicsDocument567 pagesMetallurgical Thermo Dynamicspahnin100% (4)

- Astm E2847 14Document8 pagesAstm E2847 14juncar25100% (2)

- EXPERIMENT 2 ThermoDocument5 pagesEXPERIMENT 2 ThermoDogus HurdoganogluNo ratings yet

- B787 Aft Fixed Galley. Swipe To See Close Range. Galley Inserts Have These Sizes ARINC Size 1, Arinc Size 2, Non-Arinc Size 3Document1 pageB787 Aft Fixed Galley. Swipe To See Close Range. Galley Inserts Have These Sizes ARINC Size 1, Arinc Size 2, Non-Arinc Size 3Husam FNo ratings yet

- Sustainable Heating and CoolingDocument4 pagesSustainable Heating and CoolingFritzNo ratings yet

- Tarea 4 TermodinamicaDocument3 pagesTarea 4 TermodinamicaMario GonzalezNo ratings yet

- Heat Transfer Analysis On A Straight Triangular Fin BB - Draft - 1Document15 pagesHeat Transfer Analysis On A Straight Triangular Fin BB - Draft - 1Ratandeep PandeyNo ratings yet

- Lapse Rate - Wikipedia, The Free EncyclopediaDocument6 pagesLapse Rate - Wikipedia, The Free EncyclopediaambrofosNo ratings yet

- Unit-3 Psychrometry: 3.1 Psychometric TermsDocument8 pagesUnit-3 Psychrometry: 3.1 Psychometric Termsgayakwad12_ramNo ratings yet

- The Second Law: 《 《 《 《 Physical Chemistry, 8th Edition 》 》 》 》Document20 pagesThe Second Law: 《 《 《 《 Physical Chemistry, 8th Edition 》 》 》 》febiola silvia ningsihNo ratings yet

- Calculation of Lithium Bromide JPG PDFDocument16 pagesCalculation of Lithium Bromide JPG PDFHerlan Flores100% (1)

- Student Exploration: Heat Transfer by ConductionDocument4 pagesStudent Exploration: Heat Transfer by ConductionMNightmare 503No ratings yet

- PG Brochure 2014Document59 pagesPG Brochure 2014ParinitaSahooNo ratings yet

- UNIT3-Compressible FluidsDocument26 pagesUNIT3-Compressible FluidsMatone Mafologela0% (1)

- TemperatureDocument6 pagesTemperatureNur Khairiah Daimah SanupinNo ratings yet

- V5X Tropical VRF Outdoor UnitDocument1 pageV5X Tropical VRF Outdoor UnitmohanadalhalabiNo ratings yet

- Process Engineering and Design Using Visual BasicDocument196 pagesProcess Engineering and Design Using Visual BasictayeloluNo ratings yet