Professional Documents

Culture Documents

CNC and AUTOCAD

Uploaded by

sumanth0 ratings0% found this document useful (0 votes)

65 views19 pagesOriginal Title

CNC and AUTOCAD PPT.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views19 pagesCNC and AUTOCAD

Uploaded by

sumanthCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 19

INTRO TO CNC.

LINE DIAGRAM OF CNC

IMPORTANT G- CODES.

IMPORTANT M- CODES.

INTRODUCTON TO MILLING.

INTRODUCTION TO AUTO CAD.

The term CNC is a generic term which can be used to describe many

types of device, this would include plotters, vinyl cutters, 3D printers,

milling machines and others. CNC stands for Computer Numerically

Controlled and basically means that the physical movements of the

machine are controlled by instructions, such as co-ordinate positions that

are generated using a computer.

The term CNC Machine is typically used to refer to a device which uses

a rotating cutting tool which moves in 3 or more axes (X, Y and Z) to cut-

out or carve parts in different types of materials. The information on these

pages will focus on what are typically referred to as CNC Routers

although it would be applicable to most CNC milling and engraving

machines too.

The image to the right shows a typical CNC setup with labels for some of

the key components and also an indicator showing the 3 axis of movement

(X, Y and Z) and their directions in relation to this particular machine.

This is just one example and it should be noted there are many other types,

sizes, ratios and configurations of CNC too.

Group Code Function

01 G00 Rapid positioning

01 G01 Linear interpolation

01 G02 Circular interpolation clockwise (CW)

01 G03 Circular interpolation counterclockwise (CCW)

06 G20* Inch input (in.)

06 G21* Metric input (mm)

G24 Radius programming (**)

00 G28 Return to reference point

00 G29 Return from reference point

G32 Thread cutting (**)

07 G40 Cutter compensation cancel

07 G41 Cutter compensation left

07 G42 Cutter compensation right

08 G43 Tool length compensation positive (+) direction

08 G44 Tool length compensation minus (-) direction

08 G49 Tool length compensation cancel

G84 Canned turning cycle (**)

03 G90 Absolute programming

03 G91 Incremental programming

(*) - on some machines and controls, these may be G70 (inch) and

G71 (metric)

(**) - refers only to CNC lathes and turning centers.

Code Function

M00 Program stop

M02 End of program

M03 Spindle start (forward CW)

M04 Spindle start (reverse CCW)

M05 Spindle stop

M06 Tool change

M08 Coolant on

M09 Coolant off

M10 Chuck - clamping (**)

M11 Chuck - unclamping (**)

M12 Tailstock spindle out (**)

M13 Tailstock spindle in (**)

M17 Toolpost rotation normal (**)

M18 Toolpost rotation reverse (**)

M30 End of tape and rewind

M98 Transfer to subprogram

M99 End of subprogram

(**) - refers only to CNC lathes and turning centers.

1. CNC machines can be used continuously 24 hours a day, 365 days a year

and only need to be switched off for occasional maintenance.

2. CNC machines are programmed with a design which can then be

manufactured hundreds or even thousands of times. Each manufactured

product will be exactly the same.

3. Less skilled/trained people can operate CNCs unlike manual lathes /

milling machines etc.. which need skilled engineers.

4. CNC machines can be updated by improving the software used to drive

the machines

1. CNC machines are more expensive than manually operated machines,

although costs are slowly coming down.

2. The CNC machine operator only needs basic training and skills, enough to

supervise several machines. In years gone by, engineers needed years of

training to operate centre lathes, milling machines and other manually

operated machines. This means many of the old skills are been lost.

3. Less workers are required to operate CNC machines compared to

manually operated machines. Investment in CNC machines can lead to

unemployment.

4. Many countries no longer teach pupils / students how to use manually

operated lathes / milling machines etc... Pupils / students no longer develop

the detailed skills required by engineers of the past. These include

mathematical and engineering skills.

Milling Introduction

Types of Milling Machine

1Horizontal Milling Machine

2 Vertical Milling Machine

Cutting Tools

1 Cutting Tools for Horizontal Milling Machine

2 Cutting Tools for Vertical Milling Machine

Milling machines are tools designed to machine metal, wood, and other

solid materials. Often automated, milling machines can be positioned in

either vertical or horizontal orientation to carve out materials based on a

pre-existing design.

Milling is the cutting operation that removes metal by feeding the work

against a rotating, cutter having single or multiple cutting edges. Flat or

curved surfaces of many shapes can be machined by milling with good

finish and accuracy. A milling machine may also be used for drilling,

slotting, making a circular profile and gear cutting by having suitable

attachments.

a. Column :The column houses the spindle, the bearings, the gear box, the

clutches, the shafts, the pumps, and the shifting mechanisms for transmitting

power from the electric motor to the spindle at a selected speed.

b. Knee :The knee mounted in front of the column is for supporting the table and

to provide an up or down motion along the Z axis.

c. Saddle :The saddle consists of two slide ways, one on the top and one at the

bottom located at 90 to each other, for providing motions in the X or Y axes by

means of lead screws.

d. Table :The table is mounted on top of the saddle and can be moved along the X

axis. On top of the table are some T-slots for the mounting of work piece or

clamping fixtures.

e. Arbor :The arbor is an extension of the spindle for mounting cutters. Usually,

the thread end of an arbor is of left hand helix.

f. Base: The base of the milling machine, along with the column, are the major

structural components. They hold, align, and support the rest of the machine.

There are same parts for the both vertical and horizontal milling machines.

But , there is difference in position of working of milling machine.

There fore the additional parts of vertical milling machine are:

A . Milling head The milling head consisting the spindle, the motor, and

the feed control unit is mounted on a swivel base such that it can be set at

any angle to the table.

B . Ram The ram on which the milling head is attached can be positioned

forward and backward along the slideway on the top of the column.

Cutting Tools for Horizontal Milling

A. SLAB MILL: For heavy cutting of large and flat surfaces.

B. SIDE AND FACE CUTTERS: This type of cutters has cutting

edges on the periphery and sides of the teeth for cutting

shoulders and slots.

c. SLITTING SAWS: For cutting deep slots or for parting off.

Cutting tools for Vertical Milling

A. END MILLS: Commonly used for facing, slotting and profile

milling.

B.ROUGH CUT END MILLS: For rapid metal removal.

C. SLOT DRILLS: For producing pockets without drilling a hole

before hand.

AutoCAD is a CAD software application for 2D and 3D design

In earlier releases, AutoCAD used primitive entities such as

lines

THIS SOFT WARE IS SUB DIVIDED IN TO TWO TYPES:

1:Parametric

A:Bi-directional

B:Uni-directional

2:Non-parametric

The main diffrence between parametric and non

parametricare:

In parametric we can change its dimension and sizeat any

point of time

In non-parametric if we designsome thing we cant change

its dimension and size

:

BI-DIRECTIONAL ASSOCIATE:

After saving the file also we can change its dimension at any point of time

UNI-DIRECTIONAL ASSOCIATE:

If once we save the file we cant change its dimension at any point of time

ANSI:American national standard institute

BSI :British standard institute

CSN :Chekaslovagian standard

DIN :Dutch institute of nurmong

GB :Russian standard

GOST:Chinese standard

ISO :International standard organization

BIS :Bureo indian standard

JIS :Japanese industrial standard

You might also like

- Report CNC MillingDocument16 pagesReport CNC Millingharislukman100% (5)

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Lab 6 - Face Milling On CNC MachineDocument5 pagesLab 6 - Face Milling On CNC MachineHaris NaveedNo ratings yet

- 1.0 Introduction of CNC Turning MachineDocument9 pages1.0 Introduction of CNC Turning Machineeizhar50% (4)

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Cadcam (Milling)Document29 pagesCadcam (Milling)Md Rasid SamsuriNo ratings yet

- NTM 2 CompleteDocument21 pagesNTM 2 CompleteHatim Dailaimi100% (1)

- What Can I Make With A CNC?Document6 pagesWhat Can I Make With A CNC?Nur Ain ZainuddinNo ratings yet

- CNC TURNING MachineDocument14 pagesCNC TURNING MachineFaiz AhmedNo ratings yet

- Tool and Cutter GrinderDocument6 pagesTool and Cutter GrinderNav Srinath100% (1)

- Jm201 - CNC MillingDocument24 pagesJm201 - CNC MillingMuhd Zulhusni Ag Jaludin100% (1)

- Industrial VisitDocument7 pagesIndustrial VisitKandula KrishnarjunNo ratings yet

- Me 473 - Unit 4 - 1Document70 pagesMe 473 - Unit 4 - 1Ama Serwaa YeboahNo ratings yet

- Explain Following Operations On Lathe With Suitable SketchDocument8 pagesExplain Following Operations On Lathe With Suitable SketchrajathNo ratings yet

- Lecture Cad CamDocument84 pagesLecture Cad Camismail_69No ratings yet

- Cutting Tool (Milling Machine) PerformanceDocument12 pagesCutting Tool (Milling Machine) PerformanceLashawn de MelNo ratings yet

- CNC KitDocument82 pagesCNC Kitc_pramod20001545No ratings yet

- Bachelor of Technology in Mechanical Engineering: CNC Lathe: MRR and Surface RoughnessDocument34 pagesBachelor of Technology in Mechanical Engineering: CNC Lathe: MRR and Surface RoughnessSouvikNo ratings yet

- MillingDocument5 pagesMillingSelan MatlanNo ratings yet

- DV09PUB2 Study GuideDocument5 pagesDV09PUB2 Study GuideAmirAmiriNo ratings yet

- CNC ReportDocument39 pagesCNC Reportrasaiya69% (13)

- DMP Study GuideDocument10 pagesDMP Study GuideAustin ParkerNo ratings yet

- Clone CNC MillingDocument11 pagesClone CNC MillingAmir Fikri AmranNo ratings yet

- CNC MachiningDocument6 pagesCNC MachiningZaid HassanNo ratings yet

- DV09PUB2 Study GuideDocument5 pagesDV09PUB2 Study GuideJose JulianNo ratings yet

- Milling and Machining CentersDocument5 pagesMilling and Machining CentersJose JulianNo ratings yet

- Internship Report ST EngDocument38 pagesInternship Report ST Engyasar aliNo ratings yet

- Manufacturing Processes AssignmentDocument6 pagesManufacturing Processes AssignmentAamir RafiqNo ratings yet

- Examples of CNC Machines: Punched Tape Servomechanisms MachiningDocument5 pagesExamples of CNC Machines: Punched Tape Servomechanisms MachiningTushar KhorateNo ratings yet

- Chapter 1Document17 pagesChapter 1shubhanshuNo ratings yet

- CNC Work TheoryDocument16 pagesCNC Work TheoryMeet technicalsNo ratings yet

- CNC Basic & Prog.Document89 pagesCNC Basic & Prog.Christine BrownNo ratings yet

- Introduction To CNC LatheDocument18 pagesIntroduction To CNC Lathebest4reverNo ratings yet

- Tools and Work Holding Devices of CNC MachinesDocument9 pagesTools and Work Holding Devices of CNC Machinessham javed100% (1)

- Ch-9 Shaper, Planner, SlotterDocument29 pagesCh-9 Shaper, Planner, SlotterPrateek Bayal100% (1)

- CNC Project FullDocument22 pagesCNC Project FullDebabrata NandaNo ratings yet

- CNCDocument16 pagesCNCzarepNo ratings yet

- CamDocument52 pagesCamGaurav DabhekarNo ratings yet

- CNC Milling BasicsDocument10 pagesCNC Milling Basicsjsrplc7952No ratings yet

- Vertical Machining Center: CNC (Computer Numerical Control)Document23 pagesVertical Machining Center: CNC (Computer Numerical Control)Rohith BayyaNo ratings yet

- Cam RepotrtDocument12 pagesCam RepotrtAntony NjorogeNo ratings yet

- Nota What Is CNCDocument5 pagesNota What Is CNCKebal BostNo ratings yet

- New Microsoft Office Word DocumentDocument10 pagesNew Microsoft Office Word DocumentKamaljeetNo ratings yet

- CAD/CAM Viva-Voce Questions (SVSCE Edition)Document4 pagesCAD/CAM Viva-Voce Questions (SVSCE Edition)goldencometNo ratings yet

- What Is A Machine?: Conventional MachinesDocument48 pagesWhat Is A Machine?: Conventional MachinesKranthi KumarNo ratings yet

- CNC Part ProgrammingDocument40 pagesCNC Part ProgrammingmsshahenterNo ratings yet

- CNC Part ProgrammingDocument53 pagesCNC Part ProgrammingmsshahenterNo ratings yet

- Government Polytechnic, Sirsa: Branch: Mechanical Engineering Subject: Workshop Technology - Iii Semester: 5ThDocument168 pagesGovernment Polytechnic, Sirsa: Branch: Mechanical Engineering Subject: Workshop Technology - Iii Semester: 5ThJay YadavNo ratings yet

- Lec - 9 - Milling-Gear Cutting-CNCDocument38 pagesLec - 9 - Milling-Gear Cutting-CNCsaxadi4814No ratings yet

- ULLASDocument36 pagesULLASKiranNo ratings yet

- ASSIGNMENT 1 Cad PDFDocument8 pagesASSIGNMENT 1 Cad PDFSasank SaiNo ratings yet

- Imp Lab ManualDocument36 pagesImp Lab ManualAnas MuhammedNo ratings yet

- Summary Report: RitikDocument35 pagesSummary Report: Ritikshivam modanwalNo ratings yet

- CNC MachinesDocument35 pagesCNC MachinesfitriarpNo ratings yet

- Uses of CNC Lathe MachineDocument3 pagesUses of CNC Lathe MachineKhairul IkhwanNo ratings yet

- CAM Notes 2Document15 pagesCAM Notes 2FELIX KEUYANo ratings yet

- Department of Mechanical Engineering Me1355 - Cad/Cam Lab Year: III Year Semester: VIDocument6 pagesDepartment of Mechanical Engineering Me1355 - Cad/Cam Lab Year: III Year Semester: VIT.V.B.BabuNo ratings yet

- Chapter 6 CNC MillingDocument47 pagesChapter 6 CNC MillingNEF RIDERSNo ratings yet

- Political ScienceDocument13 pagesPolitical SciencesumanthNo ratings yet

- FullDocument33 pagesFullsumanthNo ratings yet

- CNC and AutocadDocument19 pagesCNC and AutocadsumanthNo ratings yet

- FullDocument35 pagesFullsumanth100% (1)

- Minor Project ReportDocument30 pagesMinor Project ReportA 60 Rohan bansiyarNo ratings yet

- Adam-4068 DS20110819093727Document1 pageAdam-4068 DS20110819093727Paun AlNo ratings yet

- Flyer Chillers TCX and TCADocument2 pagesFlyer Chillers TCX and TCAjdbNo ratings yet

- Ambach SparesDocument44 pagesAmbach Sparesdwi purwantoNo ratings yet

- B10 Isuzu Durability Press Release-FINAL PDFDocument2 pagesB10 Isuzu Durability Press Release-FINAL PDFmasakpNo ratings yet

- 3GBP082470 BSK 3gbp082470 BSKDocument3 pages3GBP082470 BSK 3gbp082470 BSKramy alfonsNo ratings yet

- Installation Manual Apha RTDocument99 pagesInstallation Manual Apha RTJose Rodriguez33% (3)

- Panasonic NVHS820 English Operating Instruction - Owner ManualDocument26 pagesPanasonic NVHS820 English Operating Instruction - Owner ManualreconNo ratings yet

- Chapter 1 IntroductionDocument39 pagesChapter 1 IntroductionM ANo ratings yet

- Generator Synchronizing Relay: M M M M M M M MDocument2 pagesGenerator Synchronizing Relay: M M M M M M M MDINESH CHATAPNo ratings yet

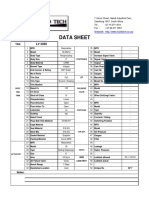

- Data Sheet: Website: HTTP://WWW - Fluidtech.co - ZaDocument1 pageData Sheet: Website: HTTP://WWW - Fluidtech.co - ZamohamedNo ratings yet

- Huawei FusionServer Pro 1288H V5 Rack Server Data SheetDocument2 pagesHuawei FusionServer Pro 1288H V5 Rack Server Data SheethasssoNo ratings yet

- "Sun Tracking Solar Panel Using Arduino Uno: Department of Electrical and Electronics EngineeringDocument11 pages"Sun Tracking Solar Panel Using Arduino Uno: Department of Electrical and Electronics Engineeringvinit naikNo ratings yet

- Yale Eletrica MS16 (A959 2015) PDFDocument94 pagesYale Eletrica MS16 (A959 2015) PDFTiago NondilloNo ratings yet

- TRIAC Control With Msp430Document36 pagesTRIAC Control With Msp430bonesisaliveNo ratings yet

- PI 800sbd+zp PDFDocument7 pagesPI 800sbd+zp PDFFernando CastilloNo ratings yet

- Description: Si PhotodiodeDocument4 pagesDescription: Si PhotodiodebobbbNo ratings yet

- Real Time Clock With Alarm Option Using AT89S52 and DS1307 ICDocument13 pagesReal Time Clock With Alarm Option Using AT89S52 and DS1307 ICkattaa1993No ratings yet

- Phantom 400Document14 pagesPhantom 400Yogendra ReddyNo ratings yet

- Kalibrasyon Ts en Iso/Iec 17025Document20 pagesKalibrasyon Ts en Iso/Iec 17025sales3 iaescoNo ratings yet

- 1006TAG ElectropaK (PN1578 75th)Document2 pages1006TAG ElectropaK (PN1578 75th)marianusNo ratings yet

- Océ 5120 User's ManualDocument172 pagesOcé 5120 User's ManualdrchapmanNo ratings yet

- Linked PDFDocument4,282 pagesLinked PDFDariusz DNo ratings yet

- RU Emu ManualDocument86 pagesRU Emu ManualEgor KaufmanNo ratings yet

- S9H1D-H4 Wdg.63 - Technical Data SheetDocument9 pagesS9H1D-H4 Wdg.63 - Technical Data SheetAkram SulaimanNo ratings yet

- Uno Minda Price ListDocument92 pagesUno Minda Price ListSanien Technologies100% (1)

- Baker Fishing 3Document8 pagesBaker Fishing 3tolufNo ratings yet

- Elecrtic Motors Universal Protection Device: Service ManualDocument31 pagesElecrtic Motors Universal Protection Device: Service ManualIgor MândruNo ratings yet

- Print PC - PC Builder - Star TechDocument1 pagePrint PC - PC Builder - Star TechTania HuqNo ratings yet

- Photoelectric Sensors: General SpecificationsDocument5 pagesPhotoelectric Sensors: General SpecificationsAnonymous AsIbqUNo ratings yet