Professional Documents

Culture Documents

276997

Uploaded by

Jhomz Baldrez0 ratings0% found this document useful (0 votes)

36 views24 pagesTUNE UP MANUAL

Original Title

1111128618_276997

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTUNE UP MANUAL

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views24 pages276997

Uploaded by

Jhomz BaldrezTUNE UP MANUAL

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 24

Manual Transmission

Diagnosis and Repair

Chapter 72

2012 Delmar, Cengage Learning

Objectives

Diagnose transmission-related problems

Remove a transmission safely in a professional

manner

Disassemble transmissions correctly

Use presses and pullers competently to

disassemble and reassemble transmissions

Diagnose and service synchronizers

Reassemble and install a transmission in a

vehicle

2012 Delmar, Cengage Learning

Introduction

Important considerations in transmission repair

Proper press and puller use

Locating service information

Disassembling transmissions

Requires controlled force

Each transmission has its own peculiarities

Synchronizers are mostly of the same design

2012 Delmar, Cengage Learning

Transmission Diagnosis

Clutch problem

Transmission doesn't go into gear

Transmission failure

Results from abuse or misapplication

Determine cause before removal

Some typical symptoms:

Gear clashing during shifting

Hard shifting and jumping out of gear

Unusual noise

2012 Delmar, Cengage Learning

Lubricant Checks

Lubricant level

Checked by removing the fill plug and inserting

your little finger inside the hole

Check for leaks

Front and rear seals

Any switches

Plug or vents

Gaskets

Oil leakage can result in transmission failure

2012 Delmar, Cengage Learning

Transmission Removal

Major steps

Removing a transmission can be dangerous

Drain gear oil before installing jack

May be necessary to remove exhaust pipes

Disconnect battery

Remove speedometer cable

Disconnect external shift linkage

Remove and clean transmission

Identify transmission before ordering parts

2012 Delmar, Cengage Learning

Transmission Disassembly

Major steps

Check service manual before disassembling

Look for damage

Gears develop normal wear pattern with use

Remove front bearing retainer and snap rings

Remove countershaft and mainshaft

Mainshaft removed from rear or top of

transmission

Remove the input shaft

Be careful not to damage gears

2012 Delmar, Cengage Learning

Disassemble the Mainshaft

Assembly

Major steps

Lay parts out as they are disassembled

Keep parts in order

High-gear synchro clutch hub

Held on mainshaft with a snap ring

Remove snap ring with snap ring pliers

Press or puller pulls synchronizer clutch hub

2012 Delmar, Cengage Learning

Synchronizer Service

Synchronizer will be

reused

Scribe line on

outside to

reassemble in

same position

Some are marked

from factory

Look for wear

Gears and shift

sleeves

2012 Delmar, Cengage Learning

Synchronizer Inspection

Best way to tell if synchro is not working

Test-drive the vehicle

Worn synchro

Causes gear clashing

Inspect synchronized gears

Rarely experience excessive wear

Inspect synchro sleeve

Even width across length

2012 Delmar, Cengage Learning

2012 Delmar, Cengage Learning

Inspect Blocker Rings

Inspect brass blocker

rings if they are to be

reused

Inside surface should

have sharp edges

Push blocker ring

against polished

tapered surface on

gear that it rides on

Should grab against

chrome surface

2012 Delmar, Cengage Learning

Inspect Input Shaft and

Mainshaft

Inspect mainshaft splines

May be twisted from abusive driving

Twisted spline prevents drive shaft slip yoke from

sliding in and out of transmission

Inspect drive gear for VSS or speedometer

Located on the output shaft

Rarely suffers damage

A special puller is available to pull these gears

2012 Delmar, Cengage Learning

Replace Worn Bearings

Use a press and support inside of bearing with

bearing separator

Reassembling: apply pressure on inside of

bearing only

2012 Delmar, Cengage Learning

Reassemble the Transmission

Before assembling

Locate and assemble any new replacement parts

Two gears operating in mesh

Create wear pattern

Gear is replaced

Corresponding gear also replaced

Using an old gear with a new gear can result in

unacceptable gear noise

2012 Delmar, Cengage Learning

Reassemble the Synchronizers

Reassemble

synchronizer hub

parts

Three inserts are

held in place with

a round spring

Install springs so

they rotate in

opposite directions

2012 Delmar, Cengage Learning

Reassemble the Mainshaft

Major steps

Install gears

Lubricate parts

liberally

Install synchro hub

Check end play of

assembled parts

2012 Delmar, Cengage Learning

End Play

Thrust washers

Control end clearance

Determine where gear

will be positioned

Check gear clearance

after all gears are

assembled

Adjust clearance by

changing thickness of

snap ring

2012 Delmar, Cengage Learning

Needle Bearing Installation

Needle bearings are

sometimes caged

Can also be loose

and installed one at a

time

Count needle

bearings during

disassembly

Service manual

Specifies number of

needle bearings

2012 Delmar, Cengage Learning

Install New Gaskets

Purchase a new transmission gasket set

Gaskets are not reusable

Gasket working fine previously could leak after

reassembly

Replacing this gasket would be a complicated

repair

Would be done at no charge to the customer

2012 Delmar, Cengage Learning

Complete the Transmission

Reassembly

Install shift mechanism

Replace extension housing bushing and seal

Use a seal installer to replace the seal without

distorting it

2012 Delmar, Cengage Learning

Install the Transmission

Major steps

Be sure clutch fork is properly seated on its pivot

Align transmission with engine

Shake transmission while rotating it back and

forth

Install bolts in transmission

Torque to specifications

2012 Delmar, Cengage Learning

Add Lubricant

Important considerations

Add recommended lubricant before driving the

vehicle

Lubricant level should come to bottom of fill hole

2012 Delmar, Cengage Learning

Test Drive

Important considerations

Be sure shifts are smooth in all gears

Neutral gate should be accurately aligned

Check outside of transmission for leaks after

returning to shop

2012 Delmar, Cengage Learning

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Strong Lifts 5x5 ReportDocument211 pagesStrong Lifts 5x5 Reportggehuz100% (2)

- African Elephant InstructionsDocument4 pagesAfrican Elephant Instructionsscope_inf3957No ratings yet

- Dan John ComplexesDocument5 pagesDan John ComplexesEzequiel Martinez Vazquez75% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Battle of The Bands RulesDocument3 pagesBattle of The Bands Rulesjesse maguiyaNo ratings yet

- Hacking The DunkDocument10 pagesHacking The Dunkapi-194148222No ratings yet

- Essence META CYOADocument36 pagesEssence META CYOAStudy New100% (1)

- 722 6Document4 pages722 6mcgyver972100% (4)

- Sports Writing Reviewer: Noren Dave AsuncionDocument15 pagesSports Writing Reviewer: Noren Dave AsuncionNoren Dave Poli Asuncion100% (1)

- SDRRM PresentationDocument51 pagesSDRRM PresentationJenelou John Israel100% (4)

- Disc Brake Components and OperationDocument8 pagesDisc Brake Components and OperationJhomz BaldrezNo ratings yet

- PanzerBlitz Article IndexDocument65 pagesPanzerBlitz Article IndexBeagle75100% (2)

- Fillable No Spiral Sheet PDFDocument2 pagesFillable No Spiral Sheet PDFLpsf PertyNo ratings yet

- Foundations of Education - LAO TZUDocument21 pagesFoundations of Education - LAO TZUJhomz BaldrezNo ratings yet

- Foundations of Education - LAO TZUDocument21 pagesFoundations of Education - LAO TZUJhomz BaldrezNo ratings yet

- Foundations of Education - LAO TZUDocument21 pagesFoundations of Education - LAO TZUJhomz BaldrezNo ratings yet

- Department of Education Division of La UnionDocument2 pagesDepartment of Education Division of La UnionJhomz BaldrezNo ratings yet

- EvaluationDocument6 pagesEvaluationJhomz BaldrezNo ratings yet

- TechnolympicsDocument14 pagesTechnolympicsJhomz BaldrezNo ratings yet

- Self Learning Module IN: InternetDocument12 pagesSelf Learning Module IN: InternetJhomz BaldrezNo ratings yet

- EvaluationDocument6 pagesEvaluationJhomz BaldrezNo ratings yet

- Als-Est Automotive Servicing NC I Competency ChecklistDocument2 pagesAls-Est Automotive Servicing NC I Competency ChecklistJhomz BaldrezNo ratings yet

- Training Manual DCP 2018Document100 pagesTraining Manual DCP 2018Jhomz BaldrezNo ratings yet

- Locator and Blank Authority TeachersDocument4 pagesLocator and Blank Authority TeachersJhomz BaldrezNo ratings yet

- TG in Automotive PDFDocument21 pagesTG in Automotive PDFMaramina Matias Roxas - MallariNo ratings yet

- Auto M2 - L123Document63 pagesAuto M2 - L123Jhomz BaldrezNo ratings yet

- Grade 10 Learning Competency Planner for TVET AutomotiveDocument19 pagesGrade 10 Learning Competency Planner for TVET AutomotiveJhomz Baldrez50% (2)

- Assessment Rubric For Class Presentation: Category A B C D FDocument1 pageAssessment Rubric For Class Presentation: Category A B C D FKhawar RiazNo ratings yet

- Letter of Endorsement for Teacher's Training ProgramDocument1 pageLetter of Endorsement for Teacher's Training ProgramJhomz BaldrezNo ratings yet

- Session Plan-Gas Engine Tune UpDocument16 pagesSession Plan-Gas Engine Tune UpJeffrey RamirezNo ratings yet

- CoolantDocument80 pagesCoolantJhomz BaldrezNo ratings yet

- Grade 7 - SCIENCE: Learning Competency PlannerDocument19 pagesGrade 7 - SCIENCE: Learning Competency PlannerJhomz BaldrezNo ratings yet

- EditingDocument20 pagesEditingJhomz BaldrezNo ratings yet

- School Registration FormDocument1 pageSchool Registration FormErnilyn Ligan100% (3)

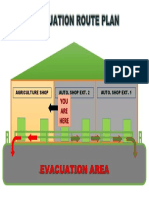

- Agriculture & Auto Shop Extensions 1 & 2Document1 pageAgriculture & Auto Shop Extensions 1 & 2Jhomz BaldrezNo ratings yet

- BLG 6 EvacDocument1 pageBLG 6 EvacJhomz BaldrezNo ratings yet

- Constitution and By-Laws (g9 Tve - Ajm)Document6 pagesConstitution and By-Laws (g9 Tve - Ajm)Jhomz BaldrezNo ratings yet

- Code of DisciplineDocument2 pagesCode of DisciplineJhomz BaldrezNo ratings yet

- Diversity Management at Work PlaceDocument31 pagesDiversity Management at Work PlaceJhomz BaldrezNo ratings yet

- How To Check Your Brake SystemDocument13 pagesHow To Check Your Brake SystemJhomz BaldrezNo ratings yet

- Ahtletics THEORY 1º EsoDocument10 pagesAhtletics THEORY 1º EsoCristina GarciaNo ratings yet

- 145-PLA Welding - Product RangeDocument3 pages145-PLA Welding - Product RangemiladrahimianNo ratings yet

- FIFA 2015 Womens World Cup Schedule and Scoresheet TemplateDocument35 pagesFIFA 2015 Womens World Cup Schedule and Scoresheet TemplateGomv ConsNo ratings yet

- 01fjmc2016 PDFDocument26 pages01fjmc2016 PDFSaad AtherNo ratings yet

- Football Player Grade 2 ComprehensionDocument2 pagesFootball Player Grade 2 ComprehensionSaquib.MahmoodNo ratings yet

- CCR 3Document2 pagesCCR 3api-480149094No ratings yet

- The Age of Barbarians - A Guide For Post-Mordenkainen's BarbariansDocument41 pagesThe Age of Barbarians - A Guide For Post-Mordenkainen's BarbariansdiNo ratings yet

- State PCS CA Consolidation (Bihar) February 2023Document11 pagesState PCS CA Consolidation (Bihar) February 2023Atul AnandNo ratings yet

- 2022 Presidential Scholars ProgramDocument8 pages2022 Presidential Scholars ProgramWKYC.comNo ratings yet

- January Month - Seva 2023Document3 pagesJanuary Month - Seva 2023saisri salesNo ratings yet

- YMCA 2014 Fall Program GuideDocument20 pagesYMCA 2014 Fall Program GuideWWYMCANo ratings yet

- 4tnv106t GgehcDocument22 pages4tnv106t GgehcDzmitryNo ratings yet

- Soal Uas Praktek Biostatistik Farmasi 2021Document4 pagesSoal Uas Praktek Biostatistik Farmasi 2021Dinni Nurul FadhillahNo ratings yet

- Sentence Transformation Tests from Hanoi Secondary School Olympiad English Exams (2000-2012Document15 pagesSentence Transformation Tests from Hanoi Secondary School Olympiad English Exams (2000-2012Jason KTNo ratings yet

- x3842 Roblox Premium AccountsDocument5 pagesx3842 Roblox Premium AccountsdfsdfsdfNo ratings yet

- 10RAUSDocument50 pages10RAUSfreeflysorinNo ratings yet

- Tutorial 5 QDocument3 pagesTutorial 5 QRafiqah KaisahNo ratings yet

- Korg KPR-77 Drum Machine ManualDocument5 pagesKorg KPR-77 Drum Machine ManualTomasz StasiakNo ratings yet

- Mind GamesDocument7 pagesMind GamesJamesiversonNo ratings yet

- MR +SAXOBEAT+-+score+harmonieDocument4 pagesMR +SAXOBEAT+-+score+harmonieluis floresNo ratings yet