Professional Documents

Culture Documents

Turtle Diagram (Calibration)

Uploaded by

DLCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turtle Diagram (Calibration)

Uploaded by

DLCopyright:

Available Formats

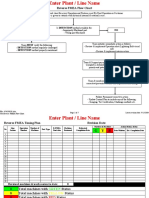

TURTLE DIAGRAM GAGE CALIBRATION

With what? With whom?

Machines/Equipment: Calibration lab equipment People involved with this process:

Standards (trace to NIST) Calibration Technician

Computer, software, printer Quality Manager

Hand tools Tool crib Attendant

Links/interfaces with involved parties:

Materials: Gage

Quality Engineering Purchasing

Cleaning supplies Process Engineering Gage Supplier

Inputs? Customer wants: Process Name Outputs? Customer need is

Gage calibration per fulfilled for:

schedule CCAL-D03 ___________________

Gage Calibration Calibrated and recorded gage

Input requirements. What are the Process Steps/Activities: per schedule CCAL-D03

inputs that determine what the Output requirements. What output

process must produce? _________________________

Receive Gage and Clean

criteria are used to determine that the

_________________________

Verify and Adjust (if required) output meets the input requirements?

Calibration schedule

Record Results

_________________________ Calibration records

Production schedule

Control plans _________________________

Release Gage Inspection and MSA results

Customer requirements Int./Ext. Customer feedback

JAN ROOVERS ASSOCIATES, INC.

Measure? How?

With what key criteria? Measurements/Assessments: Support processes: (Who helps and how?)

Gage performance Product Engineering Process Engineering

Gage availability Production Planning External Laboratory

Training Maintenance

Cost of calibration

Procedures/work instructions/control documents:

Audits

Calibration instructions Records, Database

Measurement System Analysis (MSA) records Manufacturers manuals Control plans

You might also like

- Turtle Diagram PPAPDocument1 pageTurtle Diagram PPAPDL50% (2)

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- Poison Test Sheet: Inspector Name: DateDocument2 pagesPoison Test Sheet: Inspector Name: DateDinesh Kumar100% (4)

- W.I - Abnormal SituationDocument1 pageW.I - Abnormal Situation25april100% (2)

- Meenakshi Polymers Pvt. LTD.: Poison Test SheetDocument2 pagesMeenakshi Polymers Pvt. LTD.: Poison Test SheetKaran Malhi100% (2)

- Poison Cake Test: Standard Operating ProcedureDocument1 pagePoison Cake Test: Standard Operating ProcedureGirdhar Sahu100% (3)

- Inital Flow Management Productivity ProcedureDocument4 pagesInital Flow Management Productivity Procedureshaggyrahul100% (3)

- Turtle Diagram For AuditDocument5 pagesTurtle Diagram For AuditSelvaraj Simiyon100% (3)

- RU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDocument4 pagesRU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDhananjay Patil100% (2)

- Operator observation sheet reviewDocument1 pageOperator observation sheet review25aprilNo ratings yet

- Check List For FMEA Evaluation SupplierDocument7 pagesCheck List For FMEA Evaluation SupplierMiroslaw ONo ratings yet

- IATF 16949 Documentation Toolkit GuideDocument4 pagesIATF 16949 Documentation Toolkit GuideRahul SharmaNo ratings yet

- Process & Product Audit Check SheetDocument6 pagesProcess & Product Audit Check SheetPrakashRai100% (7)

- Product Audit ReportDocument2 pagesProduct Audit ReportManoharar R100% (2)

- Guidelines For Control PlanDocument4 pagesGuidelines For Control PlanArjun Rathore100% (1)

- 11.process Turtile DiagramDocument20 pages11.process Turtile DiagrammuthuselvanNo ratings yet

- 4M Change Control Management Matrix For Supplier: MonthDocument1 page4M Change Control Management Matrix For Supplier: Monthsuresh kumar100% (3)

- APQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionDocument6 pagesAPQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionParveen KumarNo ratings yet

- 4M Change Management FormatDocument1 page4M Change Management FormatSUBODHH100% (2)

- Red Bin Analysis ProcedureDocument4 pagesRed Bin Analysis ProcedureVenkatesan92% (12)

- Internal Audit Maintenance ChecklistDocument3 pagesInternal Audit Maintenance ChecklistRamdas Paithankar100% (1)

- Manufacturing Audit ChecklistDocument8 pagesManufacturing Audit Checklistgksp100% (1)

- Procedure for PFMEA Analysis and ImprovementDocument3 pagesProcedure for PFMEA Analysis and ImprovementPk Nimiwal100% (3)

- Product audit checklist reportDocument3 pagesProduct audit checklist reportLakshmanan Venkatesan100% (8)

- Company Name: Engineering Location: Customer Name: Model Year / PlatformDocument45 pagesCompany Name: Engineering Location: Customer Name: Model Year / Platformsuresh kumar0% (1)

- Copy of APQP Check List - Ford (Blank)Document9 pagesCopy of APQP Check List - Ford (Blank)feiraluremaNo ratings yet

- Required Documents For IATF - 16949Document5 pagesRequired Documents For IATF - 16949Rajesh Sahasrabuddhe0% (1)

- 4M Change Control Management Work InstructionDocument2 pages4M Change Control Management Work InstructionSameer Saxena100% (2)

- APQP MatrixDocument2 pagesAPQP Matrixkumar QA100% (2)

- 4M Change Management For Supplier - TennecoDocument1 page4M Change Management For Supplier - TennecoOBSC PerfectionNo ratings yet

- Abnormality Handling - R2Document4 pagesAbnormality Handling - R2Sagar Daund100% (4)

- Work Instruction For Handling Abnormal Situations: Impact On Product Impact-ProcessDocument1 pageWork Instruction For Handling Abnormal Situations: Impact On Product Impact-Processhow2belive100% (1)

- Control Plan Audit FormDocument2 pagesControl Plan Audit Formdpcastilla50% (2)

- Mini DOJO ConceptDocument24 pagesMini DOJO ConceptMukesh Sharma Akshu100% (3)

- Product Audit Report SummaryDocument44 pagesProduct Audit Report SummaryEnis SirbegovicNo ratings yet

- IATF 16949 - Internal Audit ChecksheetDocument11 pagesIATF 16949 - Internal Audit ChecksheetHem Upadhyay91% (11)

- NC Closure 5 Why AnalysiDocument26 pagesNC Closure 5 Why AnalysiKaran MalhiNo ratings yet

- Evidences To Be Maintained As Per APQP For PMDocument3 pagesEvidences To Be Maintained As Per APQP For PMSachin RamdurgNo ratings yet

- Company Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportDocument1 pageCompany Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportSachin RamdurgNo ratings yet

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- Operator Observance SheetDocument5 pagesOperator Observance SheetEr Avinash Kumar100% (2)

- Poison Test PlanDocument29 pagesPoison Test PlanDinesh KumarNo ratings yet

- CS Customer - Plant Turtle Diagram 07Document1 pageCS Customer - Plant Turtle Diagram 07Alex100% (1)

- Iso Iatf Quality System Manual PDFDocument53 pagesIso Iatf Quality System Manual PDFKrishnamoorthyNo ratings yet

- Questoes Core ToolsDocument2 pagesQuestoes Core ToolsMàrcia Neruda69% (13)

- 5.1.1.2 - Process Effectiveness EfficiencyDocument1 page5.1.1.2 - Process Effectiveness EfficiencyPrakash kumarTripathiNo ratings yet

- Product Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDocument8 pagesProduct Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDavid MorenoNo ratings yet

- Rework & Repair ProcedureDocument1 pageRework & Repair ProcedureManu Sharma100% (4)

- Internal Audit ChecklistDocument37 pagesInternal Audit ChecklistSumeet Rathee100% (5)

- Reverse PFMEA Worksheet 2Document1 pageReverse PFMEA Worksheet 2adochan91% (11)

- Grand Rapids Controls LPA Checksheet AuditDocument7 pagesGrand Rapids Controls LPA Checksheet Auditalliceyew100% (3)

- IATF 16949 - 2016-Exam Paper With AnswersDocument11 pagesIATF 16949 - 2016-Exam Paper With Answersrashwin singhNo ratings yet

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- 94% Process Audit ChecklistDocument2 pages94% Process Audit ChecklistAshutosh Singh100% (2)

- Checking Aids Format for Supplier AuditsDocument3 pagesChecking Aids Format for Supplier Auditsdaniel_sasikumarNo ratings yet

- 4M Change FormatDocument1 page4M Change FormatOBSC PerfectionNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- GAGE CALIBRATION PROCESSDocument1 pageGAGE CALIBRATION PROCESSsemaphore689% (9)

- Aditya Auto APQP Phases and ElementsDocument6 pagesAditya Auto APQP Phases and ElementsSachin Ramdurg100% (1)

- The Application of Gage R&R Analysis in S Six Sigma Case of ImproDocument83 pagesThe Application of Gage R&R Analysis in S Six Sigma Case of ImproDLNo ratings yet

- FuelInjectorNozzles enDocument20 pagesFuelInjectorNozzles enVijayendran VijayNo ratings yet

- ISO 9001 - 2015 Overview and ExpectationsDocument59 pagesISO 9001 - 2015 Overview and ExpectationsAnonymous DP6iO3DfQ88% (8)

- Brian Tracy - The Miracle of Self DisciplineDocument101 pagesBrian Tracy - The Miracle of Self DisciplineJunior Kalonji96% (27)

- Reafirmacion para Los Angeles TerrenalesDocument169 pagesReafirmacion para Los Angeles TerrenalesDLNo ratings yet

- ISO 9001 2015 Audit Guide FINAL 2nd Edition PDFDocument351 pagesISO 9001 2015 Audit Guide FINAL 2nd Edition PDFlingushilloNo ratings yet

- Iso v.2008 To v.2015 Transition by Iso!Document10 pagesIso v.2008 To v.2015 Transition by Iso!LNo ratings yet

- Lofland Donald - Elimina Los Virus Mentales Con PNLDocument182 pagesLofland Donald - Elimina Los Virus Mentales Con PNLCándido Roberto Rodríguez Báez100% (7)

- I A Fid 9 Transition 9001 Publication VersionDocument30 pagesI A Fid 9 Transition 9001 Publication VersionDLNo ratings yet

- NQA ISO 9001 2015 Gap Analysis DocumentDocument4 pagesNQA ISO 9001 2015 Gap Analysis DocumentHaitham Negm100% (5)

- ISO 9001:2015 QMS Implementation ProgramDocument6 pagesISO 9001:2015 QMS Implementation ProgramCentauri Business Group Inc.100% (7)

- The Mindfulness Acceptance Workbook For Anxiety PDFDocument286 pagesThe Mindfulness Acceptance Workbook For Anxiety PDFKeny Illanes100% (1)

- Process CardDocument72 pagesProcess CardDLNo ratings yet

- Checklis Iso9000-2000Document22 pagesChecklis Iso9000-2000Jose HernandezNo ratings yet

- HAZOP-Juan Flores RamirezDocument1 pageHAZOP-Juan Flores RamirezDLNo ratings yet

- ISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDocument116 pagesISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDL50% (2)

- Customer Specific Requirements of DAG September 2017Document8 pagesCustomer Specific Requirements of DAG September 2017DLNo ratings yet

- IATF 16949 Transition Preparing for the TransitionDocument34 pagesIATF 16949 Transition Preparing for the TransitionquycoctuNo ratings yet

- Auditors Turtle Diagrams and Waste PDFDocument4 pagesAuditors Turtle Diagrams and Waste PDFDLNo ratings yet

- ISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDocument116 pagesISO 9001 2015 and IATF 16949 Vs ISO TS 16949 2009 Comparison Matrix by American Systems Registrar PDFDL50% (2)

- Starter KitDocument29 pagesStarter KitAnonymous 52KH7Ki95No ratings yet

- PPAP Webinar Core ToolsDocument62 pagesPPAP Webinar Core ToolsDLNo ratings yet

- Auditors Turtle Diagrams and Waste PDFDocument4 pagesAuditors Turtle Diagrams and Waste PDFDLNo ratings yet

- Daily Operational Planning MeetingDocument1 pageDaily Operational Planning MeetingDLNo ratings yet

- IsoDocument54 pagesIsoFurqan Ur RashidNo ratings yet

- IsoDocument54 pagesIsoFurqan Ur RashidNo ratings yet

- L&T inspection plan for transmission hardwareDocument2 pagesL&T inspection plan for transmission hardwareAvinash Lal0% (1)

- Global Ecommerce Market Ranking 2019 001Document19 pagesGlobal Ecommerce Market Ranking 2019 001Udhas PhanchiNo ratings yet

- Tapping Into Global MarketDocument30 pagesTapping Into Global MarketSadewa KuswandiNo ratings yet

- Process Integration Scenario in SAP PI 7.1Document19 pagesProcess Integration Scenario in SAP PI 7.1Durga Prasad Anagani100% (1)

- Technology Planning 07 Strategic Plan 20070924 MTABDocument28 pagesTechnology Planning 07 Strategic Plan 20070924 MTABPattycor Cadigal RañisesNo ratings yet

- Iso TS 16949 - 6 May 2010 - AdexDocument29 pagesIso TS 16949 - 6 May 2010 - Adexsudar1477No ratings yet

- Product and Service KnowledgeDocument27 pagesProduct and Service KnowledgeSharif Ullah JanNo ratings yet

- Final Business ResearchDocument40 pagesFinal Business Researchchariza alapNo ratings yet

- Unit 10 Monopoly: Price and Output Decisions: 10.0 ObjectivesDocument22 pagesUnit 10 Monopoly: Price and Output Decisions: 10.0 ObjectivesSaid Abdi MohamudNo ratings yet

- Chapter 7,8Document9 pagesChapter 7,8Hesham AhmedNo ratings yet

- Bend AllowanceDocument2 pagesBend AllowancemorohiNo ratings yet

- Start A Side HustleDocument12 pagesStart A Side HustleKaleemullah Arif bashaNo ratings yet

- BCG Matrix UNILEVER PDFDocument10 pagesBCG Matrix UNILEVER PDFIbrahim Elmorsy Maintenance - 3397No ratings yet

- PPC 2marksDocument22 pagesPPC 2marksS20M048 HARIRAM MNo ratings yet

- 1.1 - Partnership - Prashant ChandraDocument2 pages1.1 - Partnership - Prashant Chandraprashant chandraNo ratings yet

- Marketing Discount and Mark UpDocument2 pagesMarketing Discount and Mark Upapi-626793321No ratings yet

- Bill of Materials: Milling Machine Tail StockDocument1 pageBill of Materials: Milling Machine Tail StockSK ARIF MAHAMMADNo ratings yet

- Process Identification Part 2Document16 pagesProcess Identification Part 2hover.dragon16No ratings yet

- Transportation Management TMDocument52 pagesTransportation Management TMAjaykhattar100% (18)

- 101 Ijmperdjun2019101Document8 pages101 Ijmperdjun2019101TJPRC PublicationsNo ratings yet

- Unit 6 Selection and Implementation of New Technologies - Automation DecisionsDocument17 pagesUnit 6 Selection and Implementation of New Technologies - Automation DecisionsAnonymous bTh744z7E6No ratings yet

- Strategic management concepts under 40 charactersDocument3 pagesStrategic management concepts under 40 charactersHussainNo ratings yet

- Accenture Next Generation Route Market CapabilitiesDocument12 pagesAccenture Next Generation Route Market Capabilitiesaylin kadirdagNo ratings yet

- MKT205 Chapter 4Document22 pagesMKT205 Chapter 4Thenappan GanesenNo ratings yet

- Sap Pi Idea & AutomationDocument5 pagesSap Pi Idea & AutomationSuruchi BhowmikNo ratings yet

- Part 7: Communicating ValueDocument9 pagesPart 7: Communicating Valuehitesh_rimNo ratings yet

- Building Brand Community on the Harley-Davidson Posse RideDocument4 pagesBuilding Brand Community on the Harley-Davidson Posse RideGaurav jainNo ratings yet

- A Framework of Supply Chain Management LiteratureDocument11 pagesA Framework of Supply Chain Management LiteratureThuraMinSwe100% (1)

- Theory of ConstraintsDocument9 pagesTheory of ConstraintsDanNo ratings yet