Professional Documents

Culture Documents

Iron Carbon System

Uploaded by

gregkilaton0 ratings0% found this document useful (0 votes)

33 views16 pagesIron Carbon System

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIron Carbon System

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views16 pagesIron Carbon System

Uploaded by

gregkilatonIron Carbon System

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 16

IRON CARBON SYSTEM

Intro, Allotropy, Iron, Steel, etc.

INTRODUCTION

Alloys of iron carbon system includes steel and

cast iron

Steels: carbon content upto 2%

Cast irons: carbon content above 2%

Because of its outstanding commercial

importance, the iron-carbon system has been

studied in more detail than most alloy system

MICRO-CONSTITUENTS OF IRON AND STEEL

Steel when heated above austenitic temperature

and cooled under differential condition, the

austenite in steel transforms into variety of

micro-constituents

Various micro-constituents are

a) Austenite

b) Ferrite

c) Cementite

d) Pearlite

e) Bainite

f) Martensite

g) Troostite

h) Sorbite

AUSTENITE

Solid solution of carbon and/or other alloying

elements (e.g., Mn, Ni, etc.) in gamma iron

Carbon is in interstitial solid solution with iron

Austenite can dissolve max 2% carbon @ 1130˚C

Normally unstable at room temperature

Non-magnetic and soft

FERRITE

BCC iron phase with very limited solubility for

carbon (max sol 0.025% carbon @723˚C)

Dissolves only 0.008% C @ room temperature

Softest structure that appears on Fe-C

equilibrium diagram

CEMENTITE

Cementite or iron carbide (Fe3C), contains 6.67%

C by weight

Typically hard and brittle interstitial compound

Hardest structure that appears on Fe-C diagram

Crystal structure is orthorhombic

LEDEBURITE

Eutectic mixture of austenite and cementite

Contains 4.3% C @ 1130˚C

PEARLITE

Consist of alternate lamellae of ferrite and

cementite

Product of austenite decomposition of eutectoid

reaction

Eutectoid mixture of containing 0.8% C and is

formed @ 723˚C

IRON CARBON EQUILIBRIUM

DIAGRAM

INTRO

Fe-C equilibrium diagram forms a basis for

differentiating among iron (0.008%C or less),

hypoeutectoid steels (0.008%-0.8%C),

hupereutectoid steels (0.8%-2.0%C), hypoeutectic

CI (2%-4.3%C) and hypereutectic CI (above

4.3%C)

Has a peritectic, a eutectic and a eutectoid

Peritectic equation may be written as

cooling

Delta (δ) + liquid Austenite

heating

Horizontal line @ 2720 F shows peritectic reaction

Eutectic reaction may be written as

Liquid Austenite + cementite

[eutectic mixture (ledeburite)]

Takes place @ 2066 F (4.3%C)

Eutectoid reaction

Represented by horizontal line @ 1333 F

Solid ferrite + cementite

[eutectoid mixture (pearlite)]

HYPOEUTECTOID STEEL CONTAINING

0.4%C

Steel containing 0.4% carbon is a hypoeutectoid steel

Completely austenite above A3

Below A3 iron begins to change from FCC to BCC

BCC iron begins to separate out from austenite

BCC structure retain a small amount if carbon and referred as ferrite

As cooling proceeds, ferrite crystal grow in size at the expense of

austenite

By the time steel reaches A1 line, it is composed if half ferrite and

half austenite

At this stage austenite contains 0.83%C and since it cannot contain

more than this at 1333F, carbon precipitate as cementite if cooled

further

This cementite and still separating ferrite form alternate layers until

all austenite is consumed

The lamellae structure, i.e., eutectoid of ferrite and cementite

contains 0.83%C and is known as Pearlite

All hypoeutectoid steels when cooled from austenite state will

transform into ferrite and peralite in the same way

EUTECTOID STEEL CONTAINING 0.83%C

Will remain austenite up to point S

Transformation begins and end at the same

temperature (1333F)

Since eutectoid steel contains 0.83% carbon

initially, it follows that the final transformed

structure will be completely pearlite

HYPEREUTECTOID STEEL 1.2%C

As temperature falls and steel crosses Acm line

at point d and moves towards e, excess carbon

above the amount required to saturate austenite

(0.83%) is precipitated as cementite

Above lower critical temperature line (1333F) the

structure consists of austenite and cementite

As it is cooled further, austenite becomes less

rich in carbon and gets converted in pearlite

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- From USI Maintenance Expert in Babbitt Lining For 30 YearsDocument2 pagesFrom USI Maintenance Expert in Babbitt Lining For 30 YearsgregkilatonNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Erosion Shield Brazing Acceptance CriteriaDocument1 pageErosion Shield Brazing Acceptance CriteriagregkilatonNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Iron Carbon SystemDocument16 pagesIron Carbon SystemgregkilatonNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Finite Element AnalysisDocument113 pagesFinite Element AnalysisTochi Krishna Abhishek57% (7)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Memorandum Circular No. 03-08-2012Document20 pagesMemorandum Circular No. 03-08-2012gregkilatonNo ratings yet

- Iso 10423 - Api 6aDocument1 pageIso 10423 - Api 6agregkilaton0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- NDT Acceptance CriteriaDocument2 pagesNDT Acceptance CriteriagregkilatonNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Dye Penetrant Inspection ProcedureDocument13 pagesDye Penetrant Inspection ProcedureHafidzManaf100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- AutoCAD TrainingDocument20 pagesAutoCAD TrainingThulasi RamNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Duplex Stainless Steel Guide - Strengths, Uses & LimitationsDocument7 pagesDuplex Stainless Steel Guide - Strengths, Uses & LimitationsRizalzi BachtiarNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- How To Weld Duplex Stainless SteelDocument1 pageHow To Weld Duplex Stainless SteelgregkilatonNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 17-4 PH Against 17-7ph MaterialDocument2 pages17-4 PH Against 17-7ph MaterialgregkilatonNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- YANTRAS - What Is Their PurposeDocument5 pagesYANTRAS - What Is Their PurposegregkilatonNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Guardian Angels of The ZodiacDocument6 pagesThe Guardian Angels of The Zodiacgregkilaton100% (1)

- Application of Austenetic SSDocument2 pagesApplication of Austenetic SSgregkilatonNo ratings yet

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Astm E2375Document2 pagesAstm E2375gregkilatonNo ratings yet

- Mandrel DrawingDocument4 pagesMandrel DrawinggregkilatonNo ratings yet

- Ashitaba HerbDocument5 pagesAshitaba HerbgregkilatonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Matls For Turbine BladesDocument1 pageMatls For Turbine BladesgregkilatonNo ratings yet

- Erosion Shield Brazing Acceptance CriteriaDocument1 pageErosion Shield Brazing Acceptance CriteriagregkilatonNo ratings yet

- Commonly Used Welding CodesDocument21 pagesCommonly Used Welding CodesgregkilatonNo ratings yet

- Pan Weighing Vs Moment WeighingDocument1 pagePan Weighing Vs Moment WeighinggregkilatonNo ratings yet

- Typical Material Specifications For Major Component PartsDocument9 pagesTypical Material Specifications For Major Component PartsSampath KumarNo ratings yet

- Fan Blade Design & TestingDocument6 pagesFan Blade Design & TestinggregkilatonNo ratings yet

- Acceptable Bolting Materials in H2S Contained Environment Per NaceDocument1 pageAcceptable Bolting Materials in H2S Contained Environment Per NacegregkilatonNo ratings yet

- Pan Weighing Vs Moment WeighingDocument1 pagePan Weighing Vs Moment WeighinggregkilatonNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Filtration Handbook Filtration and Flushing Strategy PDFDocument28 pagesFiltration Handbook Filtration and Flushing Strategy PDFAlberto AliagaNo ratings yet

- Home Automation Iot Bca Up (2ND SEMINAR PPT) RTDocument30 pagesHome Automation Iot Bca Up (2ND SEMINAR PPT) RTTejaswiniNo ratings yet

- Manual de Operacion de Bomba BlackmerDocument20 pagesManual de Operacion de Bomba BlackmerMorales EduardoNo ratings yet

- Bobcat Technical Information Bulletin - CompressDocument2 pagesBobcat Technical Information Bulletin - Compressgerman orejarenaNo ratings yet

- Nādatanumanisham Shankaram Namami Me Manasa ShirasaDocument12 pagesNādatanumanisham Shankaram Namami Me Manasa Shirasaveena murthyNo ratings yet

- UG WeibullDocument776 pagesUG WeibullCharles GuzmanNo ratings yet

- Shares Dan Yang Belum Diterbitkan Disebut Unissued SharesDocument5 pagesShares Dan Yang Belum Diterbitkan Disebut Unissued Sharesstefanus budiNo ratings yet

- USB GPW CB03 MT02 - EngDocument21 pagesUSB GPW CB03 MT02 - EngRafael BispoNo ratings yet

- The Machining of Brake DiscsDocument8 pagesThe Machining of Brake DiscsBusu Cyp100% (1)

- M.E. Comm. SystemsDocument105 pagesM.E. Comm. SystemsShobana SNo ratings yet

- Epoxy Hardeners, Water-Reducible: ProductsDocument1 pageEpoxy Hardeners, Water-Reducible: ProductsDhruv SevakNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Massive MIMO For Communications With Drone SwarmsDocument26 pagesMassive MIMO For Communications With Drone SwarmsAsher Suranjith JayakumarNo ratings yet

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDocument10 pagesA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJENo ratings yet

- Satellite TestingDocument30 pagesSatellite TestingXavier Ponce Ferrufino100% (1)

- Verify scope acceptance of project deliverablesDocument5 pagesVerify scope acceptance of project deliverablesmypmpbooksNo ratings yet

- Lesson 1Document24 pagesLesson 1Jayzelle100% (1)

- Ain 2016 Pilot Report m600Document4 pagesAin 2016 Pilot Report m600Antonio Cesar de Sa LeitaoNo ratings yet

- PM Master Data Template v1Document72 pagesPM Master Data Template v1Naseer SultanNo ratings yet

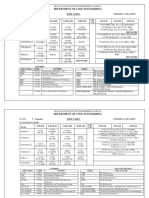

- Time TableDocument7 pagesTime TableChethan .H.GNo ratings yet

- Color Order SystemsDocument30 pagesColor Order SystemsBeyene DumechaNo ratings yet

- 1 05 Lab Crime Scene Sketch GADocument2 pages1 05 Lab Crime Scene Sketch GAthis is hardly gonna be usedNo ratings yet

- VCTDS 00543 enDocument62 pagesVCTDS 00543 enguido algaranazNo ratings yet

- Apriori AlgorithmDocument13 pagesApriori AlgorithmKiran JoshiNo ratings yet

- XS Power Batteries D Series InstructionsDocument2 pagesXS Power Batteries D Series InstructionsAutopiezas PanaNo ratings yet

- FTP FUNCTION MODULE in ABAPDocument8 pagesFTP FUNCTION MODULE in ABAPAdriano PermanaNo ratings yet

- Hot Rolled Sheet Pile SHZ Catalogue PDFDocument2 pagesHot Rolled Sheet Pile SHZ Catalogue PDFkiet eelNo ratings yet

- Material Balance of Naphtha Hydrotreater and Reformer ReactorsDocument22 pagesMaterial Balance of Naphtha Hydrotreater and Reformer ReactorsSukirtha GaneshanNo ratings yet

- GenEd Mathematics LLL PDFDocument32 pagesGenEd Mathematics LLL PDFArmely NiedoNo ratings yet

- Stereochemistry Practce PDFDocument6 pagesStereochemistry Practce PDFFerminNo ratings yet

- Excel Dynamic Arrays: Department Item Quantity Price Total $Document5 pagesExcel Dynamic Arrays: Department Item Quantity Price Total $Bilal Hussein SousNo ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To InformationJGD123No ratings yet