Professional Documents

Culture Documents

Chemical Reactions in Rusting of Iron

Uploaded by

Gagandeep SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Reactions in Rusting of Iron

Uploaded by

Gagandeep SinghCopyright:

Available Formats

Rust is a general term for describing iron oxides.

In colloquial usage, the term is applied to red oxides, formed by the reaction of iron and oxygen in the presence of water or air moisture. There are also other forms of rust, such as the result of the reaction of iron and chloride in an environment deprived of oxygen, such as rebar used in underwater concrete pillar which generates green rust. Several forms of rust are distinguishable visually and by spectroscopy, and form under different circumstances. Rust consists of hydrated iron(III) oxides Fe2O3nH2O and iron(III) oxide-hydroxide FeO (OH)Fe(OH)3.

Given sufficient time, oxygen, and water, any iron mass will eventually convert entirely to rust and disintegrate. Surface rust provides no protection to the underlying iron, unlike the formation of patina on copper surfaces. Rusting is the common term for corrosion of iron and its alloys, such as steel. Many other metals undergo equivalent corrosion, but the resulting oxides are not commonly called rust.

When impure (cast) iron is in contact with water, oxygen, or other strong oxidants, or acids, it rusts. If salt is present, for example in seawater or salt spray, the iron tends to rust more quickly, as a result of electrochemical reactions. Iron metal is relatively unaffected by pure water or by dry oxygen. As with other metals, like aluminiun, a tightly adhering oxide coating, a passivation layer, protects the bulk iron from further oxidation. The conversion of the passivating iron oxide layer to rust results from the combined action of two agents, usually oxygen and water. Other degrading solutions are sulfur dioxide in water and carbon dioxide in water. Under these corrosive conditions, iron hydroxide species are formed. Unlike iron oxides, the hydroxides do not adhere to the bulk metal. As they form and flake off from the surface, fresh iron is exposed, and the corrosion process continues until either all of the iron is consumed or all of the oxygen, water, carbon dioxide, or sulfur dioxide in the system are removed or consumed.

The rusting of iron is an electrochemical process that begins with the transfer of electrons from iron to oxygen. The rate of corrosion is affected by water and accelerated by electrolytes, as illustrated by the effects of road salt on the corrosion of automobiles. The key reaction is the reduction of oxygen: O2 + 4e + 2H2O 4OHBecause it forms hydroxide ions, this process is strongly affected by the presence of acid. Indeed, the corrosion of most metals by oxygen is accelerated at low pH. Providing the electrons for the above reaction is the oxidation of iron that may be described as follows: Fe Fe2+ + 2eThe following redox reaction also occurs in the presence of water and is crucial to the formation of rust: 4Fe2+ + O2 4Fe3+ + 2O2In addition, the following multistep acid-base reactions affect the course of rust formation:

Fe2+ + 2H2O Fe(OH)2 + 2H+Fe3+ + 3H2O Fe(OH)3 + 3H+as do the

following dehydration equilibria :

Fe(OH)2 FeO + H2OFe(OH)3 FeO(OH) + H2O2FeO(OH) Fe2O3 + H2O Rusted pyrite cubes embedded in a stony matrix From the above equations, it is also seen that the corrosion products are dictated by the availability of water and oxygen. With limited dissolved oxygen, iron(II)-containing materials are favoured, including FeO and black lodestone (Fe3O4). High oxygen concentrations favour ferric materials with the nominal formulae Fe(OH)3-xOx/2. The nature of rust changes with time, reflecting the slow rates of the reactions of solids. Furthermore, these complex processes are affected by the presence of other ions, such asCa2+, both of which serve as an electrolyte, and thus accelerate rust formation, or combine with the hydroxides and oxides of iron to precipitate a variety of Ca-FeO-OH species. A chemical rust indicator can be used for testing the presence of

Because of the widespread use and importance of iron and steel products, the prevention or slowing of rust is the basis of major economic activities in a number of specialized technologies. A brief overview of methods is presented here; for detailed coverage, see the cross-referenced articles. Rust is permeable to air and water, therefore the interior metallic iron beneath a rust layer continues to corrode. Rust prevention thus requires coatings that preclude rust formation.

You might also like

- 2.electrochemical CorrosionDocument2 pages2.electrochemical CorrosionSahil VishwakarmaNo ratings yet

- Difference Between Rust and CorrosionDocument5 pagesDifference Between Rust and Corrosionhutsonianp100% (2)

- Co 2Document17 pagesCo 2sreeram chowdharyNo ratings yet

- Carbon Steel Corrosion in Clay-Rich EnvironmentDocument10 pagesCarbon Steel Corrosion in Clay-Rich Environmentblackcurse29No ratings yet

- What Is CorrosionDocument4 pagesWhat Is CorrosionOsransyah Os100% (1)

- Article CO2CorrosionCHEM409 - Background of CO2 CorrosionDocument4 pagesArticle CO2CorrosionCHEM409 - Background of CO2 Corrosionmohamed samyNo ratings yet

- AI Hempadur Quattro XO 17870 EnglishDocument4 pagesAI Hempadur Quattro XO 17870 EnglishLuka BornaNo ratings yet

- 7 Forms of Corrosion IDocument39 pages7 Forms of Corrosion IJesus De la RosaNo ratings yet

- CorrosionDocument14 pagesCorrosionChalakAhmedNo ratings yet

- Atmospheric Corrosion MechanismDocument27 pagesAtmospheric Corrosion MechanismmghgolNo ratings yet

- Corrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips BurnersDocument13 pagesCorrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips Burnersravikanth_rNo ratings yet

- Salt TestDocument16 pagesSalt Testم.ذكى فضل ذكى100% (1)

- Wet Storage Stain On Galvanized SteelDocument8 pagesWet Storage Stain On Galvanized SteelDino PedutoNo ratings yet

- Review On Automotive Body Coating ProcessDocument4 pagesReview On Automotive Body Coating ProcessIJEMR JournalNo ratings yet

- Corrosion Under Insulation: A JPCL EresourceDocument47 pagesCorrosion Under Insulation: A JPCL Eresourcefahny100% (1)

- CuiDocument6 pagesCuiأحمد صبحىNo ratings yet

- Atmospheric Corrosion of Materials PDFDocument24 pagesAtmospheric Corrosion of Materials PDFMarcos LeiteNo ratings yet

- Welding International Volume 25 Heat Tint Colours On Stainless Steel and Welded JointsDocument5 pagesWelding International Volume 25 Heat Tint Colours On Stainless Steel and Welded JointsAPINo ratings yet

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDocument13 pagesEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyMad Max100% (1)

- Corrosion Inhibitors in Conversion Coatings. IIIDocument7 pagesCorrosion Inhibitors in Conversion Coatings. IIIAnonymous 6tg80e6BqANo ratings yet

- Galvanic CorrDocument6 pagesGalvanic CorrdhlinvaNo ratings yet

- Thermal Spray ProcessesDocument235 pagesThermal Spray ProcessesHasham AyubNo ratings yet

- Corrosion Problems in The Oil IndustryDocument8 pagesCorrosion Problems in The Oil IndustryUNIISCRIBDNo ratings yet

- Duplex SystemDocument9 pagesDuplex Systemnightmanmx100% (1)

- 3 1 Eight Forms CorrosionDocument20 pages3 1 Eight Forms CorrosionIbraheem KhressNo ratings yet

- Pa 3 PDFDocument0 pagesPa 3 PDFNageswara Rao BavisettyNo ratings yet

- The Life Cycle Costing of Corrosion in The Oil and Gas Industry: A GuidelineDocument58 pagesThe Life Cycle Costing of Corrosion in The Oil and Gas Industry: A Guidelineamine bouizarNo ratings yet

- Content: Aim of The ProjectDocument31 pagesContent: Aim of The ProjectDevi MeenakshiNo ratings yet

- Pitting CorrosionDocument29 pagesPitting Corrosionatikahj_3No ratings yet

- Flow in Flow-Accelerated Corrosion For Nuclear Power PlantDocument16 pagesFlow in Flow-Accelerated Corrosion For Nuclear Power PlantSalih Gürkan üyümezNo ratings yet

- D 4940 Â " 98 R03 RDQ5NDADocument3 pagesD 4940 Â " 98 R03 RDQ5NDAEnrique Rodriguez LunaNo ratings yet

- Corrosion: IntroducingDocument29 pagesCorrosion: Introducingkeval patelNo ratings yet

- Wet Storage Stain On Galvanized SteelDocument5 pagesWet Storage Stain On Galvanized Steele.vicente.caballeroNo ratings yet

- In-Situ Subsurface Coating of Corroded Steel Sheet Pile StructuresDocument142 pagesIn-Situ Subsurface Coating of Corroded Steel Sheet Pile StructuresyaofuzhangNo ratings yet

- Coating SDocument51 pagesCoating SBalaji GuruNo ratings yet

- Corrosion Management Issue140 LowResDocument32 pagesCorrosion Management Issue140 LowResReno100% (1)

- Filiform CorrosionDocument10 pagesFiliform CorrosionVisnu DrxsNo ratings yet

- Surface Preparation Standards - ComparasionDocument4 pagesSurface Preparation Standards - ComparasiontaiNo ratings yet

- Multiple Choice 11 Stainless SteelDocument3 pagesMultiple Choice 11 Stainless SteelThomas TuckerNo ratings yet

- Chem Unit 2 CorrosionAndItsControl PDFDocument18 pagesChem Unit 2 CorrosionAndItsControl PDFMohamed AbdouNo ratings yet

- White Rust PreventionDocument16 pagesWhite Rust PreventionSreedhar Patnaik.MNo ratings yet

- Protective Coat Surface PreparationsDocument6 pagesProtective Coat Surface Preparationsengineeringchemistry0% (1)

- Filming Corrosion Inhibitor For Oil and Gas FieldDocument20 pagesFilming Corrosion Inhibitor For Oil and Gas FieldelsyakiebNo ratings yet

- Corrosion & Non-Ferrous MetalDocument21 pagesCorrosion & Non-Ferrous Metalsiraphat.bmNo ratings yet

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical IndustriesDocument3 pagesAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining and Petrochemical IndustriesMahmoud Elmahdy100% (1)

- Corrosion (Compatibility Mode) 2Document54 pagesCorrosion (Compatibility Mode) 2Omkar Kumar JhaNo ratings yet

- Unit4.Protective Coats 4 CivilDocument5 pagesUnit4.Protective Coats 4 CivilengineeringchemistryNo ratings yet

- Review of Stress Corrosion Cracking of PipelineDocument6 pagesReview of Stress Corrosion Cracking of PipelinevladNo ratings yet

- Duplex Coatings, TSA, ZN Sprayed Coating, Sealer, Duplex, Ships, Oil&gasDocument40 pagesDuplex Coatings, TSA, ZN Sprayed Coating, Sealer, Duplex, Ships, Oil&gasXiaohua Chen100% (1)

- Zinc Silicate PrimersDocument9 pagesZinc Silicate PrimersminhnnNo ratings yet

- Form of Corrosion Illustration Form of Corrosion IllustrationDocument2 pagesForm of Corrosion Illustration Form of Corrosion IllustrationkhalesnabilNo ratings yet

- Coating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryDocument43 pagesCoating As An Ideal Prevention For Corrosion in Manufacture and Infrastructure IndustryLarasanto Larasanto100% (1)

- TMS: Thermal Metal Spray Coatings: Corrosion Engineering DivisionDocument7 pagesTMS: Thermal Metal Spray Coatings: Corrosion Engineering DivisionCorrosion Factory100% (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Amorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryFrom EverandAmorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryNo ratings yet

- Biological Treatment of Microbial Corrosion: Opportunities and ChallengesFrom EverandBiological Treatment of Microbial Corrosion: Opportunities and ChallengesNo ratings yet

- Reaction Paper-RprDocument6 pagesReaction Paper-Rprapi-543457981No ratings yet

- Nitric AcidDocument7 pagesNitric AcidKuldeep BhattNo ratings yet

- GEC - ReviewerDocument23 pagesGEC - ReviewerGlycel BagabagonNo ratings yet

- Contractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountDocument1 pageContractor: Item No. MRS-1st 2021 Ref. Description Unit Quantity Rate of Contractor Unit Rate in Words AmountusmanaliNo ratings yet

- 204-04B - Tire Pressure Monitoring System (TPMS)Document23 pages204-04B - Tire Pressure Monitoring System (TPMS)Sofia AltuzarraNo ratings yet

- Maintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBDocument10 pagesMaintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBAtaa AssaadNo ratings yet

- Bio411 C1Document1 pageBio411 C1Aqiena BalqisNo ratings yet

- TC 10 emDocument7 pagesTC 10 emDina LydaNo ratings yet

- DOWSIL™ 2-9034 Emulsion: Features & BenefitsDocument5 pagesDOWSIL™ 2-9034 Emulsion: Features & BenefitsLaban KantorNo ratings yet

- ASD Diagnosis Tools - UpToDateDocument3 pagesASD Diagnosis Tools - UpToDateEvy Alvionita Yurna100% (1)

- Education in America: The Dumbing Down of The U.S. Education SystemDocument4 pagesEducation in America: The Dumbing Down of The U.S. Education SystemmiichaanNo ratings yet

- Women and ViolenceDocument8 pagesWomen and ViolenceStyrich Nyl AbayonNo ratings yet

- FEM 3004 - Lab 10 Part 2editedDocument26 pagesFEM 3004 - Lab 10 Part 2editedAINA NADHIRAH BINTI A ROZEY / UPMNo ratings yet

- High Speed DoorsDocument64 pagesHigh Speed DoorsVadimMedooffNo ratings yet

- Electrical Data: PD2310 ApplicationsDocument1 pageElectrical Data: PD2310 ApplicationsKSNo ratings yet

- Ventricular Septal DefectDocument8 pagesVentricular Septal DefectWidelmark FarrelNo ratings yet

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaDocument53 pagesGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADNo ratings yet

- Feeder BrochureDocument12 pagesFeeder BrochureThupten Gedun Kelvin OngNo ratings yet

- D6228 - 10Document8 pagesD6228 - 10POSSDNo ratings yet

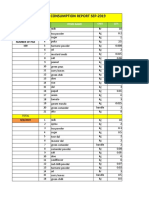

- Daily Staff Food Consumption Reports Sep-2019Document4 pagesDaily Staff Food Consumption Reports Sep-2019Manjit RawatNo ratings yet

- Task 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Document5 pagesTask 5 Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoNo ratings yet

- Big 9 Master SoalDocument6 pagesBig 9 Master Soallilik masrukhahNo ratings yet

- 7-Multiple RegressionDocument17 pages7-Multiple Regressionحاتم سلطانNo ratings yet

- CrewmgtDocument36 pagesCrewmgtDoddy HarwignyoNo ratings yet

- PolydactylyDocument43 pagesPolydactylyWara Samsarga GedeNo ratings yet

- Lesson 1 - Intro To Highway EngineeringDocument15 pagesLesson 1 - Intro To Highway EngineeringSaoirseNo ratings yet

- Discharge PlanDocument3 pagesDischarge PlanBALOGO TRISHA MARIENo ratings yet

- Guideline On Smacna Through Penetration Fire StoppingDocument48 pagesGuideline On Smacna Through Penetration Fire Stoppingwguindy70No ratings yet

- Funding HR2 Coalition LetterDocument3 pagesFunding HR2 Coalition LetterFox NewsNo ratings yet

- J130KDocument6 pagesJ130KBelkisa ŠaćiriNo ratings yet